This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

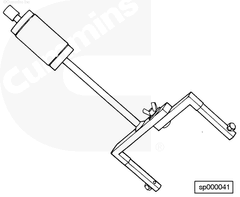

The Puller, M.B. Cap (Part #3375356) by Cummins is a specialized tool designed for the maintenance and operation of commercial trucks. This component is integral to the efficient removal and installation of various truck components, ensuring that maintenance tasks are performed with precision and safety.

Basic Concepts

The Puller, M.B. Cap functions as a mechanical device used to extract components such as bearings, gears, and shafts from their housings. It operates by applying force to the component, allowing for its safe and effective removal without causing damage. The tool consists of several components, including a cap that fits over the component, a puller mechanism, and attachment points for applying force. Understanding these basic concepts is fundamental to utilizing this Cummins part effectively in truck maintenance.

Purpose and Role

The primary purpose of the Puller, M.B. Cap is to facilitate the removal and installation of truck components. It plays a significant role in maintenance operations by ensuring that components can be extracted and replaced with minimal risk of damage. This tool is particularly useful in scenarios where components are tightly fitted or require precise alignment during installation.

Key Features

The Puller, M.B. Cap is designed with several key features that enhance its performance and durability. It is constructed from high-quality materials to withstand the rigors of commercial truck maintenance. The design includes a cap that securely fits over the component, a robust puller mechanism, and ergonomic handles for operator comfort. These features contribute to the tool’s effectiveness and longevity.

Benefits

Using the Puller, M.B. Cap offers several benefits in truck maintenance. It improves efficiency by allowing for quicker and more precise component removal and installation. The tool reduces the risk of damage to components during maintenance tasks, which can save time and resources. Additionally, it enhances safety for operators by providing a controlled method for applying force, minimizing the potential for injury 1.

Troubleshooting and Maintenance

To ensure the Puller, M.B. Cap remains in optimal condition, regular maintenance and troubleshooting are recommended. Common issues may include wear on the cap or puller mechanism, which can be addressed by inspecting the tool regularly and replacing worn parts as needed. Proper storage in a dry, clean environment will also contribute to the tool’s longevity 2.

Application in Truck Maintenance

The Puller, M.B. Cap is commonly used in various truck maintenance scenarios. It is designed to work with components such as bearings, gears, and shafts, facilitating their removal and installation. Specific applications may include the maintenance of transmission systems, differentials, and engine components. Following manufacturer guidelines for use ensures the tool is applied correctly in these scenarios.

Safety Considerations

When using the Puller, M.B. Cap, several safety considerations should be taken into account. Proper handling techniques are crucial to prevent injury and ensure the tool’s effectiveness. Operators should wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against potential hazards. Awareness of the tool’s limitations and the specific requirements of the maintenance task at hand will contribute to a safe working environment 3.

Cummins Overview

Cummins is a renowned manufacturer with a strong reputation in the automotive and heavy-duty truck industry. The company is committed to quality and innovation, producing a wide range of components and tools designed to enhance the performance and reliability of commercial vehicles. Cummins’ dedication to excellence is evident in their products, including the Puller, M.B. Cap, which embodies the company’s focus on durability, efficiency, and safety in truck maintenance.

Conclusion

The Puller, M.B. Cap (Part #3375356) by Cummins is a vital tool in the maintenance and operation of commercial trucks. Its design and features ensure efficient, safe, and precise removal and installation of truck components, contributing to the overall performance and reliability of commercial vehicles. Regular maintenance and adherence to safety guidelines are essential to maximize the tool’s effectiveness and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.