This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

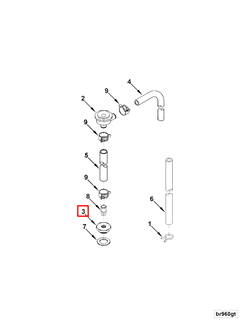

The Cummins 3356363 Filler Cap is a vital component in the fueling systems of commercial trucks. It ensures the secure and efficient transfer of fuel into the tank, contributing to the reliability and performance of the truck’s fueling system.

Purpose and Function

This Cummins part allows fuel to be introduced into the tank while preventing contaminants and vapors from escaping. It creates a seal that maintains the integrity of the fuel system, ensuring that fuel is contained within the tank and that the system operates under the correct pressure conditions. This cap is integral to the safe and efficient operation of the truck’s fuel system 1.

Key Features

The 3356363 Filler Cap is designed with features that enhance its performance and durability. It is typically made from materials resistant to corrosion and wear, ensuring longevity in demanding environments. The cap incorporates sealing mechanisms that provide a tight seal, preventing fuel leakage and the ingress of contaminants. Unique attributes may include an ergonomic design for ease of use and a venting system that allows for safe pressure release during fueling 2.

Benefits

The advantages provided by the 3356363 Filler Cap include improved fuel containment, which helps to maintain the correct fuel levels and prevents fuel loss. Its resistance to wear and corrosion ensures that it can withstand the rigors of regular use in commercial trucking. Additionally, the cap’s design contributes to ease of use for truck operators, simplifying the fueling process and reducing the risk of spills or accidents 3.

Installation and Usage

Proper installation of the 3356363 Filler Cap involves ensuring that it is correctly aligned with the fuel tank opening and securely fastened. Usage instructions typically include opening the cap by turning it counterclockwise to release the seal, fueling the truck, and then closing the cap by turning it clockwise until it clicks, indicating a secure seal. Specific instructions or precautions may be provided to ensure optimal performance and safety during operation.

Maintenance and Care

Routine maintenance of the 3356363 Filler Cap includes regular cleaning to remove any dirt or debris that may accumulate, inspection for signs of wear or damage, and replacement if necessary. Care should be taken to ensure that the sealing surfaces remain clean and undamaged to maintain the integrity of the seal. Following manufacturer guidelines for maintenance will help prolong the cap’s lifespan and ensure continued reliable operation.

Troubleshooting Common Issues

Common problems that may arise with the 3356363 Filler Cap include leaks or difficulty in operation. Troubleshooting steps may involve checking the cap for proper alignment and secure fastening, inspecting the sealing surfaces for damage or contamination, and ensuring that the venting system is not obstructed. Solutions may include cleaning the cap and sealing surfaces, or replacing the cap if it is damaged or worn.

Safety Considerations

When handling and maintaining the 3356363 Filler Cap, it is important to follow safety precautions and best practices. This includes proper handling of fuel to prevent spills and accidents, adherence to manufacturer guidelines for installation and maintenance, and ensuring that the fueling area is well-ventilated and free from ignition sources. These practices help to ensure the safe and effective use of the filler cap.

Environmental Impact

The use and disposal of the 3356363 Filler Cap have environmental considerations. Efforts to minimize waste and pollution may include recycling options for the cap and its components, as well as responsible disposal practices. Cummins Inc. and other manufacturers are increasingly focused on developing products that are environmentally friendly and sustainable, reflecting a commitment to reducing the environmental impact of their products.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for a variety of applications, including commercial trucking.

Compatibility with Cummins Engines

The Cummins part number 3356363, identified as a Filler Cap, is designed to fit seamlessly with a range of Cummins engines. This filler cap is a crucial component that ensures the proper sealing and maintenance of the engine’s fuel or coolant systems.

4B3.9 Engine

The 4B3.9 engine is a part of the Cummins B Series engines, known for their reliability and efficiency. The filler cap 3356363 is specifically engineered to fit the fuel system of the 4B3.9 engine. It ensures that the fuel tank remains sealed, preventing contamination and ensuring optimal fuel quality. The cap is designed to withstand the operational pressures and temperatures of the engine, providing a durable and long-lasting solution.

6B5.9 Engine

The 6B5.9 engine, another member of the Cummins B Series, also benefits from the use of the filler cap 3356363. This cap is integral to the engine’s coolant system, ensuring that the coolant reservoir remains sealed. Proper sealing is critical for maintaining the correct coolant levels and preventing the ingress of contaminants, which can lead to engine damage. The cap’s design ensures a secure fit, making it easy to install and remove during routine maintenance.

Grouping of Engines

Both the 4B3.9 and 6B5.9 engines fall under the Cummins B Series, which is renowned for its robust performance and durability. The filler cap 3356363 is compatible with these engines due to its universal design, which adheres to the specifications required by Cummins for these models. This compatibility ensures that the filler cap provides the necessary sealing and protection for both fuel and coolant systems across these engine types.

Role of Part 3356363 Filler Cap in Engine Systems

Part 3356363 Filler Cap is integral to the efficient operation of several engine components, ensuring optimal performance and longevity. When integrated with the breather system, this filler cap allows for the controlled release of pressure built up within the crankcase. This is essential for maintaining a stable environment within the crankcase, preventing undue stress on seals and gaskets.

In conjunction with the crankcase, the filler cap plays a part in the ventilation process. As the engine operates, it generates gases and vapors that need to be expelled to avoid contamination and pressure build-up. The filler cap, working in tandem with the crankcase ventilation system, ensures these byproducts are effectively managed.

Furthermore, when paired with a breather kit, the filler cap enhances the overall efficiency of the breather system. The breather kit typically includes various components designed to regulate airflow and pressure within the engine. The filler cap, as a component of this kit, contributes to the seamless operation of these elements, ensuring that the engine maintains peak performance under varying conditions.

Conclusion

In summary, part 3356363 Filler Cap is a key component in the ventilation and pressure management systems of engine components, working in harmony with the breather, crankcase, and breather kit to ensure the engine operates efficiently and reliably.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Peters, George, and Barbara J Peters. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.