This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

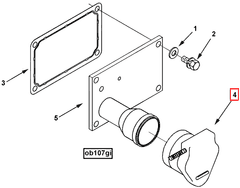

Introduction

The Cummins 3252100 Filler Cap is a component designed for use in commercial trucks. It ensures the secure and efficient transfer of fuel into the tank, maintaining the operational integrity of the vehicle’s fuel system and contributing to the overall efficiency and reliability of the truck 1.

Purpose and Function

The 3252100 Filler Cap acts as a barrier between the fuel tank and the external environment, facilitating the secure connection of a fuel dispenser nozzle. It is engineered to prevent fuel spillage and contamination, ensuring clean fuel during the refueling process. Additionally, it maintains the pressure within the fuel tank, which is crucial for the proper operation of the vehicle’s fuel system 2.

Key Features

The design of the 3252100 Filler Cap incorporates high-quality materials resistant to wear and environmental factors. It includes a sealing mechanism for a tight fit on the fuel tank, preventing leaks. Unique design elements may include a venting system to release pressure build-up within the tank, facilitating a smoother fueling process.

Benefits

The 3252100 Filler Cap offers improved fuel containment, reducing the risk of spills and environmental contamination. Its resistance to wear ensures a longer service life, and its design contributes to ease of use for the operator, making the refueling process more convenient and efficient.

Installation and Usage

Proper installation of the 3252100 Filler Cap is crucial for optimal performance. The installation process involves securing the cap onto the fuel tank opening, ensuring a tight seal. Usage is straightforward, requiring the operator to align the fuel dispenser nozzle with the cap and press to initiate fuel transfer. Ensuring the cap is properly seated after refueling maintains the integrity of the fuel system.

Maintenance and Care

Routine maintenance of the 3252100 Filler Cap is important for its longevity and performance. This includes regular cleaning to remove dirt or debris, and periodic inspection for wear or damage, particularly on the sealing surfaces. If wear or damage is detected, replacement should be considered to ensure the continued efficiency and safety of the fuel system.

Troubleshooting Common Issues

Common problems with the 3252100 Filler Cap include leaks or difficulty in operation. Leaks may indicate wear on the sealing surfaces or damage to the cap, requiring inspection and possible replacement. Difficulty in operation, such as the cap not seating properly, may be due to debris or misalignment, which can often be resolved through cleaning and proper alignment during installation.

Safety Considerations

When handling and maintaining the 3252100 Filler Cap, it is important to observe safety practices and precautions. This includes adhering to manufacturer guidelines and industry standards for the handling of fuel system components. Safety considerations also encompass the proper use of personal protective equipment when performing maintenance tasks, to protect against potential hazards associated with fuel and its vapors.

Environmental Impact

The use and disposal of the 3252100 Filler Cap have environmental considerations. Proper waste management practices should be followed to minimize environmental impact. This includes recycling options for the cap, if available, and ensuring that any waste is disposed of in accordance with local regulations and guidelines.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing products and services that drive progress in the transportation, construction, mining, oil and gas, and power generation industries.

Role of Part 3252100 Filler Cap in Engine Systems

The 3252100 Filler Cap is integral to the engine’s maintenance and operation, ensuring that the fuel system remains sealed and protected from contaminants. It is designed to fit seamlessly with several engine models, including the ISM CM570, ISM CM570/870, QSM11 CM570, K19, L10 MECHANICAL, M11 CELECT PLUS, and N14 MECHANICAL engines, ensuring a secure fit and reliable performance.

Integration with Key Components

The 3252100 Filler Cap interfaces with the oil fill system, allowing for the addition of oil to the engine. It is connected to the oil fill cover, cylinder block, oil pan, valve and EBM cover, oil level and gauge, hand hole cover, and oil gauge and oil pan cover. This integration ensures the engine receives the necessary lubrication for optimal performance and longevity.

Conclusion

The Cummins 3252100 Filler Cap plays a crucial role in the fueling and lubrication systems of commercial trucks. Its design and features ensure secure fuel transfer, maintain fuel system integrity, and contribute to the overall efficiency and reliability of the vehicle. Proper installation, maintenance, and adherence to safety practices are essential for the optimal performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.