This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

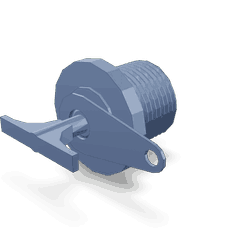

Understanding the Cummins 3102287 Filler Cap for Commercial Trucks

Introduction to Cummins

Cummins, a global leader in diesel engines and related components, is synonymous with reliability and innovation. Their extensive range of products is designed to meet the demanding needs of commercial trucking, ensuring optimal performance and durability. Among their many offerings, the Cummins 3102287 Filler Cap stands out as a critical component in the maintenance and operation of commercial truck engines.

Introduction to the 3102287 Filler Cap

The Cummins 3102287 Filler Cap is an essential part of the fuel system in commercial trucks. This component is specifically designed to ensure the safe and efficient filling of diesel fuel while preventing contamination and maintaining the integrity of the fuel system. Its robust design and precise engineering make it a vital element in the overall performance and longevity of truck engines.

Basic Concepts Related to Filler Caps

A filler cap, in general, serves as the primary seal for the fuel tank, allowing for the addition of fuel while preventing spills, leaks, and the ingress of contaminants. The design typically includes a sealing mechanism that ensures a tight fit, often incorporating materials like rubber or silicone to maintain an effective seal over time 1.

How a Filler Cap Works

The mechanics of a filler cap involve a simple yet effective design. When the cap is screwed onto the fuel tank, a sealing ring within the cap creates a barrier that prevents fuel from escaping and contaminants from entering. The materials used are chosen for their durability and resistance to the chemicals found in diesel fuel, ensuring long-term reliability 2.

Purpose of the Cummins 3102287 Filler Cap

The Cummins 3102287 Filler Cap plays a crucial role in the operation of a truck engine by maintaining proper fuel levels and ensuring that the fuel remains uncontaminated. This is vital for the engine’s performance, as clean fuel is essential for efficient combustion and power generation. Additionally, the filler cap is a key component in routine maintenance, directly impacting the engine’s longevity and overall performance.

Importance in Maintenance

Regular inspection and maintenance of the filler cap are critical. A well-maintained filler cap ensures that the fuel system operates efficiently, reducing the risk of engine damage and extending the lifespan of the engine. It also plays a role in preventing fuel spills, which can be hazardous and costly 3.

Troubleshooting and Maintenance Suggestions

Common issues with filler caps include leaks, cracks, and improper sealing. These problems can lead to fuel loss, contamination, and potential engine damage. To address these issues, it is important to perform regular inspections and replace the filler cap if any signs of wear or damage are detected. Ensuring that the cap is properly tightened after fueling can also prevent many common problems.

Maintenance Best Practices

To ensure optimal performance and longevity of the Cummins 3102287 Filler Cap, it is recommended to follow these best practices:

- Inspect the filler cap regularly for signs of wear, cracks, or leaks.

- Ensure the cap is properly tightened after each fueling to maintain a secure seal.

- Replace the filler cap if any damage is detected to prevent fuel loss and contamination.

- Keep the area around the filler cap clean to avoid introducing contaminants into the fuel system.

Cummins’ Commitment to Quality

Cummins is renowned for its commitment to quality, which is evident in the production of the 3102287 Filler Cap. The company employs rigorous quality assurance processes to ensure that each component meets the highest standards of durability and performance. Cummins also integrates innovative technologies and materials into their designs, enhancing the functionality and reliability of their products.

Expert Insights and Best Practices

Industry experts emphasize the importance of proper handling and maintenance of filler caps. Regular inspections and timely replacements are crucial to prevent costly engine damage. Real-world case studies have shown that neglecting the maintenance of filler caps can lead to significant issues, including fuel contamination and engine failure. Therefore, it is essential to adhere to best practices and manufacturer recommendations 4.

Conclusion

The Cummins 3102287 Filler Cap is a critical component in the fuel system of commercial trucks, ensuring safe and efficient fuel filling while preventing contamination. Regular maintenance and inspection of the filler cap are vital for the engine’s performance and longevity. Cummins’ commitment to quality and innovation ensures that their filler caps are reliable and durable, making them a trusted choice for commercial trucking applications. Prioritizing the maintenance and proper use of filler caps is essential for engineers, mechanics, truck drivers, and fleet operators to ensure optimal engine performance and longevity.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety

↩ -

Quansheng Zhang, Shengbo Eben, Li Kun Deng, Automotive Air Conditioning: Optimization, Control and Diagnosis

↩ -

Tom Denton, Automotive Technician Training

↩ -

Andrew Livesey, The Repair of Vehicle Bodies

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.