This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

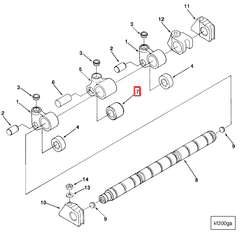

The 3895487 Cam Follower Roller, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the engine manufacturing industry, produces this part to enhance the performance and reliability of truck engines. Cam follower rollers play a role in the operation of an engine by facilitating the transfer of motion from the camshaft to the valve train, ensuring precise and efficient valve operation 1.

Basic Concepts of Cam Follower Rollers

Cam follower rollers are components within an engine that interact directly with the camshaft. Their primary function is to convert the rotational motion of the camshaft into linear motion for the valve train. This conversion allows for the opening and closing of engine valves at precise intervals, which is important for the engine’s combustion process. Roller-type cam followers, like the 3895487, are specifically designed to reduce friction and wear between the camshaft and the valve train components. They achieve this by rolling over the cam lobes instead of sliding, which minimizes contact stress and enhances the longevity of the engine components 2.

Purpose of the 3895487 Cam Follower Roller

The 3895487 Cam Follower Roller is integral to the operation of a truck engine. It translates the motion from the camshaft to the valve train, ensuring that the valves open and close at the correct times. This precise timing is vital for the engine’s performance, fuel efficiency, and emissions control. By facilitating smooth and efficient valve operation, the 3895487 Cam Follower Roller contributes to the overall reliability and efficiency of the truck’s engine 3.

Key Features

The 3895487 Cam Follower Roller boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that offer superior resistance to wear and corrosion. The design includes precision-machined rollers that ensure smooth operation and minimal friction. Additionally, the roller’s unique attributes, such as its robust construction and advanced engineering, contribute to its ability to withstand the high stresses and temperatures encountered in commercial truck engines 4.

Benefits

The use of the 3895487 Cam Follower Roller in a truck engine offers several benefits. It contributes to improved engine efficiency by ensuring precise valve timing and reducing friction within the valve train. This results in enhanced fuel economy and reduced emissions. Furthermore, the roller’s design helps to minimize wear on engine components, leading to longer engine life and reduced maintenance costs. The overall performance of the truck is also enhanced, providing smoother operation and increased reliability 1.

Installation and Usage

Proper installation of the 3895487 Cam Follower Roller is crucial for its effective operation within the engine system. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly and efficiently. During installation, attention should be paid to aligning the roller with the camshaft and ensuring it is securely fastened. Once installed, the roller operates within the engine system by rolling over the cam lobes, transferring motion to the valve train, and facilitating the opening and closing of the engine valves 2.

Troubleshooting

Common issues associated with cam follower rollers include noise, increased friction, and premature wear. These issues can often be identified through routine engine inspections and diagnostic tests. To address potential problems with the 3895487 Cam Follower Roller, a step-by-step troubleshooting guide should be followed. This may involve inspecting the roller for signs of wear or damage, checking the alignment and fit within the engine, and ensuring that all related components are in good condition. If issues are detected, the roller may need to be adjusted, repaired, or replaced to restore optimal engine performance 3.

Maintenance

To ensure the longevity and optimal performance of the 3895487 Cam Follower Roller, recommended maintenance practices should be followed. This includes regular inspections to check for signs of wear or damage, cleaning the roller and surrounding components to remove any debris or contaminants, and lubricating as necessary to reduce friction and wear. The frequency of inspections and maintenance procedures will depend on the engine’s operating conditions and usage. When significant wear or damage is detected, consideration should be given to replacing the roller to prevent further engine issues 4.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to quality and innovation in the industry. With a rich history of producing reliable and high-performance engine components, Cummins has established a reputation for excellence. The company’s dedication to research and development ensures that its products, like the 3895487 Cam Follower Roller, meet the demanding requirements of commercial truck applications. Cummins’ focus on quality, durability, and performance makes it a trusted name in the engine manufacturing sector 1.

Cummins Cam Follower Roller 3895487 in L10 Engines

The Cummins Cam Follower Roller 3895487 is a component in the L10 engine family, which includes both the L10 CELECT and L10 MECHANICAL variants. This part plays a role in the engine’s operation by ensuring smooth and efficient interaction between the camshaft and the valve train.

In the L10 CELECT engine, the Cam Follower Roller 3895487 is designed to work seamlessly with the engine’s electronic control system. This integration allows for precise control over valve timing and lift, enhancing the engine’s performance and fuel efficiency. The CELECT variant’s advanced technology benefits from the reliability and durability of the Cummins Cam Follower Roller, ensuring consistent engine operation under varying conditions.

Similarly, in the L10 MECHANICAL engine, the Cam Follower Roller 3895487 is engineered to provide robust performance. This engine relies on mechanical linkages for valve operation, and the roller’s design supports the high-stress environment of the valve train. The roller’s ability to maintain a tight clearance with the camshaft is crucial for minimizing friction and wear, thereby extending the engine’s lifespan.

Both engines benefit from the precision engineering of the Cummins Cam Follower Roller 3895487, which is crafted to meet the stringent demands of heavy-duty applications. This part’s compatibility with both the L10 CELECT and L10 MECHANICAL engines underscores its versatility and importance in maintaining engine integrity and performance 2.

Understanding the Role of Part 3895487 Cam Follower Roller in Engine Systems

The part 3895487 Cam Follower Roller is a component in the operation of various engine systems, particularly in the interaction between the camshaft and the valve train. This component facilitates smooth and efficient motion transfer from the camshaft to the cam follower lever, ensuring precise valve timing and operation 3.

Interaction with the Cam Follower

The Cam Follower Roller, identified by part number 3895487, directly contacts the camshaft lobes. Its primary function is to translate the rotational motion of the camshaft into linear motion of the cam follower. This translation is vital for the opening and closing of engine valves at the correct times, which is fundamental for engine performance and efficiency 4.

Role in the Cam Follower Lever Mechanism

When the Cam Follower Roller engages with the camshaft, it exerts force on the Cam Follower Lever. This lever then amplifies the motion, transferring it to the valve mechanism. The roller’s design minimizes friction and wear, ensuring that the lever operates smoothly and reliably over the engine’s lifespan 1.

Integration with the Campaign Kit

In scenarios where engine modifications or upgrades are necessary, the Campaign Kit often includes the Cam Follower Roller. This kit may contain various components designed to enhance engine performance, and the roller ensures that the new camshaft’s profile is accurately followed, maintaining the intended performance improvements 2.

Contribution to the Camshaft Kit

The Camshaft Kit, which typically includes high-performance camshafts and associated components, relies on the Cam Follower Roller for optimal function. The roller’s precision and durability are key to handling the increased stresses and higher RPMs that performance camshafts introduce, ensuring that the valve train operates efficiently and reliably 3.

Conclusion

In summary, the part 3895487 Cam Follower Roller plays a role in the coordination and efficiency of engine systems by ensuring smooth and accurate motion transfer from the camshaft to the valve train components. Its integration with the cam follower, cam follower lever, campaign kit, and camshaft kit underscores its importance in both standard and high-performance engine applications 4.

-

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ ↩ ↩ ↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ ↩ ↩ ↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ ↩ ↩ ↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.