3070499

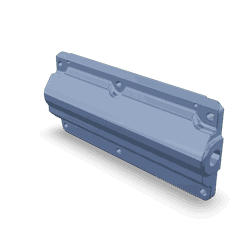

Cam Follower Housing

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3070499 Cam Follower Housing is a critical component in the valve train system of heavy-duty truck engines. It ensures precise and reliable valve operation, contributing to the engine’s performance and efficiency. This part is designed to facilitate the operation of heavy-duty trucks by maintaining the engine’s timing and reducing wear on critical components 1.

Basic Concepts of Cam Follower Housing

A Cam Follower Housing is a protective enclosure that houses the cam follower, which interacts directly with the camshaft to control the opening and closing of engine valves. The housing includes components such as the cam follower, bearing surfaces, and lubrication channels. Its primary function is to provide a stable and lubricated environment for the cam follower, reducing wear and ensuring smooth operation 2.

Role of the 3070499 Cam Follower Housing in Truck Operation

The Cummins 3070499 Cam Follower Housing is designed to enhance the operation of heavy-duty truck engines by ensuring that the cam follower operates within a controlled environment. This minimizes friction and wear, contributing to precise valve timing, efficient combustion, and power delivery. Additionally, it reduces noise and vibration, leading to smoother engine operation 3.

Key Features of the 3070499 Cam Follower Housing

The Cummins 3070499 Cam Follower Housing is constructed from high-strength materials to withstand the rigors of heavy-duty truck operation. It features precise machining for optimal fit and function, and advanced lubrication channels to ensure consistent oil flow to critical components, enhancing longevity and performance.

Benefits of Using the 3070499 Cam Follower Housing

Incorporating the Cummins 3070499 Cam Follower Housing into truck engines offers several benefits, including improved engine performance through accurate valve timing and reduced friction. Its durable construction and advanced design elements enhance the engine’s reliability and longevity. Precise engineering helps maintain consistent engine operation, leading to better fuel efficiency and reduced maintenance requirements.

Installation Process

Installing the Cummins 3070499 Cam Follower Housing requires careful attention to detail. The process involves removing the old housing, inspecting the camshaft and valve train components for wear, and then installing the new housing. Specific tools may be required to ensure proper alignment and torque specifications are met. It is important to follow the manufacturer’s guidelines to ensure a successful installation.

Common Issues and Troubleshooting

Common issues with the Cummins 3070499 Cam Follower Housing may include wear on the cam follower, lubrication problems, or misalignment. Troubleshooting steps involve inspecting the housing for signs of wear or damage, ensuring proper lubrication, and checking the alignment of the cam follower with the camshaft. Regular maintenance and timely replacement of worn components can prevent many issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3070499 Cam Follower Housing, regular maintenance is recommended. This includes checking the lubrication system to ensure consistent oil flow, inspecting the housing for signs of wear or damage, and replacing any worn components as necessary. Additionally, following the manufacturer’s recommended service intervals for inspection and maintenance will help in maintaining the housing’s performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the automotive industry, particularly in the heavy-duty truck sector, Cummins is known for its high-quality, reliable, and innovative products. The company’s commitment to excellence and customer satisfaction has established it as a leader in the industry.

Cummins Cam Follower Housing 3070499 Compatibility

The Cummins Cam Follower Housing part number 3070499 is designed to fit seamlessly with several engine models, ensuring compatibility and reliability across different engine types. This part is integral to the engine’s operation, providing a housing for the camshaft followers, which are essential for the smooth functioning of the engine’s valve train.

Compatible Engines

- G855

- N14 CELECT PLUS

- N14 MECHANICAL

These engines benefit from the precise fit and robust construction of the Cummins Cam Follower Housing 3070499, ensuring optimal performance and longevity.

Additional Compatibility

- QSN14 CM876 N103

- QSNT14 CM876 N102

The part 3070499 also fits these engines, providing the same level of reliability and performance. This compatibility extends across these models, ensuring that the housing meets the specific needs of each engine variant.

By ensuring that the Cam Follower Housing 3070499 is compatible with these engines, Cummins maintains a high standard of quality and performance, making it a reliable choice for engine maintenance and repair.

Understanding the Integration of Part 3070499 Cam Follower Housing in Engine Systems

The part 3070499 Cam Follower Housing is an integral component in the orchestration of various engine systems, ensuring the seamless operation of the engine’s mechanical functions. This housing is designed to accommodate the cam follower lever, which plays a significant role in the valve train mechanism of an engine.

Interaction with the Block and Cylinder

The Cam Follower Housing is strategically positioned within the engine block, adjacent to the cylinder. Its primary function is to provide a stable and secure environment for the cam follower lever. This lever, in turn, is responsible for translating the rotational motion of the camshaft into linear motion, which is essential for the opening and closing of the engine’s valves. The housing’s precise location within the block ensures minimal friction and maximum efficiency in this motion transfer.

Role in the Valve Train Mechanism

In conjunction with the cam follower lever, the Cam Follower Housing contributes to the overall efficiency of the valve train. The valve train is a series of components that control the timing and duration of the valve’s opening and closing. The housing’s role is to support the lever as it interacts with the camshaft, ensuring that the valve operation is smooth and consistent. This is particularly important in high-performance engines where precision and reliability are paramount.

Integration with the Campaign Kit

When part of a campaign kit, the Cam Follower Housing is often included to address specific issues or improvements identified in the engine’s design or operation. The campaign kit may contain updated or modified components, including the housing, to enhance engine performance, reliability, or to correct a known issue. The housing’s integration into such a kit underscores its importance in maintaining or upgrading the engine’s operational standards.

Synergy with the Follower and Cam

The Cam Follower Housing works in tandem with the follower and cam to ensure the engine’s valves operate in sync with the piston’s movement. The follower, which is housed within the Cam Follower Housing, makes direct contact with the cam. This contact is what drives the lever, and subsequently, the valve. The housing’s design must account for the dynamic forces at play during engine operation, providing a durable and reliable interface between the follower, lever, and cam.

Conclusion

The Cummins 3070499 Cam Follower Housing plays a vital role in the operation of heavy-duty truck engines. Its precise design and robust construction ensure optimal performance and longevity. By understanding its integration within the engine system and following proper maintenance practices, users can maximize the benefits of this critical component.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.