This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

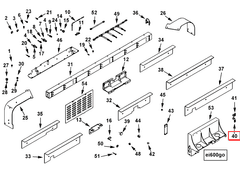

The Cummins 4016354 Cable Bracket is a component designed for use in commercial trucks. Its primary role is to support and secure cables within the truck’s electrical and mechanical systems. A cable bracket, in general, serves to organize and protect cables, ensuring they remain in place and function correctly under various operating conditions 1.

Purpose and Function

This Cummins part is specifically engineered to hold and route cables in commercial truck applications. It plays a role in maintaining the integrity of the truck’s electrical and mechanical systems by securing cables, which helps prevent damage from vibrations and other dynamic forces encountered during operation. This bracket ensures that cables are positioned correctly, reducing the risk of interference with other components and enhancing the overall reliability of the truck’s systems 2.

Key Features

The 4016354 is constructed from durable materials, designed to withstand the harsh environments typical of commercial truck operations. Its design includes features such as mounting points and cable guides, which facilitate easy installation and secure cable placement. The bracket’s robust construction contributes to its longevity and effectiveness in protecting cables from wear and tear 3.

Benefits

Using this part offers several advantages. It improves cable management by keeping cables organized and protected, which can lead to fewer electrical issues and easier troubleshooting. The bracket’s durable design enhances the longevity of the cables it protects, potentially reducing maintenance costs. Additionally, by ensuring cables are securely in place, the bracket contributes to the overall efficiency and safety of the truck 4.

Installation and Compatibility

Proper installation of the 4016354 involves securing it to the truck’s frame or chassis using the appropriate fasteners. It may require tools such as wrenches or drills, depending on the specific installation scenario. Compatibility with various truck models and systems should be verified to ensure optimal performance and integration within the truck’s existing infrastructure.

Maintenance and Troubleshooting

Regular maintenance of the 4016354 includes inspecting it for signs of wear or damage and ensuring that cables remain securely fastened. Common issues may include loose brackets or damaged cables, which can be addressed by tightening fasteners or replacing worn components. Adhering to a maintenance schedule can help prevent more significant problems and ensure the bracket continues to perform its intended function effectively.

Safety Considerations

When installing or maintaining the 4016354, it is important to follow safety guidelines. This includes using the appropriate tools and personal protective equipment to prevent injuries. Additionally, ensuring that the bracket is correctly installed and secured can help avoid operational issues that could pose safety risks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 4016354, which is designed to meet the demanding requirements of commercial truck applications.

Role of 4016354 Cable Bracket in Engine Systems

The 4016354 is an essential component in the integration and organization of various engine systems. It facilitates the secure attachment and routing of cables, ensuring efficient operation and maintenance of the engine.

Integration with Accessories

In engine systems, the Cable Bracket plays a significant role in the integration of accessories. It provides a stable mounting point for cables that connect accessories such as turbochargers, fuel injectors, and air conditioning systems. By securing these cables, the bracket ensures that accessories receive consistent power and signals, which is vital for their reliable operation.

Electrical System Support

The electrical system of an engine relies heavily on the proper routing and protection of cables. The 4016354 supports this by holding cables in place, preventing them from coming into contact with moving parts or heat sources. This not only protects the integrity of the electrical signals but also enhances the safety and reliability of the engine’s electrical components.

Mounting and Organization

Effective cable management is key to maintaining a clean and organized engine compartment. The 4016354 aids in this by providing designated points for cable attachment. This organization reduces the risk of cable damage and makes it easier for mechanics to access and service various engine components.

Engine Monitor Connectivity

Engine monitors require precise and consistent data to function correctly. The 4016354 ensures that the cables connecting sensors and monitors are securely routed and protected. This reliability in data transmission is essential for accurate engine performance monitoring and diagnostics.

Conclusion

In summary, the 4016354 is a fundamental component in the efficient and safe operation of engine systems, supporting the integration of accessories, the reliability of the electrical system, the organization of cables, and the accurate functioning of engine monitors.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.