This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

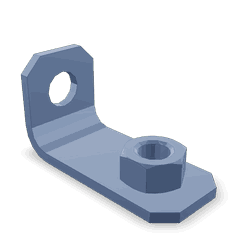

The Cummins 4009289 Cable Bracket is a component designed to facilitate the organization and secure placement of cables within commercial trucks. Its role is integral to maintaining the efficiency and reliability of the truck’s electrical system, ensuring that cables are neatly routed and protected from potential damage 1.

Basic Concepts of Cable Brackets

A cable bracket serves as a mounting point for cables, providing a structured pathway that helps in organizing and securing them. In the context of a truck’s electrical system, cable brackets play a role in preventing cable tangling, reducing the risk of electrical shorts, and ensuring that cables remain in place despite the vibrations and movements typical of truck operations 2.

Purpose of the 4009289 Cable Bracket

This Cummins part is specifically designed to secure and organize cables within a truck’s electrical system. By providing a designated space for cables, it helps in maintaining an orderly cable layout, which is crucial for the proper functioning of electrical components. This bracket ensures that cables are less likely to come into contact with moving parts or sharp edges, thereby reducing the risk of damage 3.

Key Features

The 4009289 is constructed from durable materials, ensuring it can withstand the harsh conditions often encountered in commercial trucking. Its design includes features such as pre-drilled holes for easy cable attachment and a robust structure that offers reliable support. Additionally, the bracket is engineered to accommodate various cable sizes, providing flexibility in its application.

Benefits of Using the 4009289 Cable Bracket

Utilizing this Cummins part offers several advantages. It enhances cable management by providing a structured pathway for cables, which helps in reducing the likelihood of electrical issues caused by cable tangling or damage. The bracket’s durable construction ensures long-lasting performance, contributing to the overall reliability of the truck’s electrical system.

Installation Process

Installing the 4009289 involves several steps to ensure it is securely and effectively placed. Begin by identifying the optimal location for the bracket, considering the routing of cables and the proximity to electrical components. Use the appropriate tools to attach the bracket to the truck’s frame, ensuring it is firmly in place. Route the cables through the bracket, securing them as necessary to maintain an organized layout.

Troubleshooting Common Issues

Common issues with cable brackets may include loose connections or damage to the bracket itself. To address these problems, first, ensure that all connections are secure and that the bracket is firmly attached to the truck’s frame. Inspect the bracket for any signs of damage, and replace it if necessary to maintain the integrity of the cable management system.

Maintenance Tips

Regular maintenance of the 4009289 is important to ensure its continued effectiveness. Inspect the bracket periodically for signs of wear or damage, and tighten any loose connections. Keeping the area around the bracket clean and free of debris will also help in maintaining its performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted partner for truck manufacturers and operators worldwide.

Cable Bracket 4009289 Compatibility with Cummins Engines

The Cable Bracket part number 4009289, manufactured by Cummins, is designed to integrate seamlessly with specific models of Cummins engines. This part is essential for maintaining the structural integrity and operational efficiency of the engine’s cable management system.

QSK19 Series

The QSK19 series engines, including the QSK19 CM500 and QSK19 CM850 MCRS, are equipped with the Cable Bracket 4009289. This bracket is crucial for the proper routing and securing of various cables within the engine compartment. Its design ensures that cables are held in place, preventing any potential damage or interference with engine components.

QSK19 CM500

In the QSK19 CM500 engine, the Cable Bracket 4009289 is strategically positioned to manage the cables associated with the engine’s control systems. Its placement is critical for maintaining the alignment and tension of these cables, which are vital for the engine’s performance and reliability.

QSK19 CM850 MCRS

Similarly, in the QSK19 CM850 MCRS engine, the Cable Bracket 4009289 plays a pivotal role in the cable management system. This bracket ensures that all cables are securely fastened and properly routed, which is essential for the engine’s operational efficiency and longevity. The MCRS designation indicates that this engine is part of the Marine Command Response System, further emphasizing the importance of precise cable management.

By using the Cable Bracket 4009289, these engines benefit from enhanced cable management, which contributes to overall engine performance and ease of maintenance.

Role of Part 4009289 Cable Bracket in Engine Systems

The 4009289 Cable Bracket is an essential component in the arrangement of various engine systems, ensuring secure and efficient operation. It plays a significant role in the integration and support of multiple engine components.

Turbocharger Integration

In turbocharger systems, the 4009289 Cable Bracket is used to secure cables that connect the turbocharger to the engine control unit (ECU). This ensures that the communication between the turbocharger and the ECU remains uninterrupted, allowing for precise control over boost levels and engine performance. The bracket helps in maintaining the correct tension and routing of the cables, which is vital for the turbocharger’s efficient operation.

Cooler Systems

When dealing with engine cooler systems, such as oil or charge air coolers, the 4009289 Cable Bracket supports the cables that monitor and control the cooling process. It ensures that sensors and actuators connected to the cooler are properly positioned and secured, allowing for accurate temperature readings and effective cooling management. This contributes to the overall reliability and performance of the engine.

Engine Oil Systems

In engine oil systems, the 4009289 Cable Bracket is instrumental in securing cables that connect to oil pressure sensors and other monitoring devices. By keeping these cables in place, the bracket ensures that the engine oil pressure is consistently monitored, allowing for timely detection of any issues related to oil flow or pressure. This helps in maintaining optimal engine lubrication and preventing potential damage.

Cover and Hand Hole Applications

The bracket also finds its use in securing cables around engine covers and hand holes. In these applications, it ensures that cables do not interfere with the opening and closing of covers or obstruct access to hand holes. This is particularly important during maintenance procedures, where easy access to various engine components is necessary. The 4009289 Cable Bracket helps in keeping the workspace organized and safe, reducing the risk of accidental damage to cables or other components.

Conclusion

The Cummins 4009289 Cable Bracket is a vital component in the maintenance and operation of commercial truck electrical systems. Its design and features contribute to the efficient management of cables, ensuring the reliability and performance of the truck’s electrical and engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.