This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4001004 Cable Bracket is a component designed to facilitate the secure routing and organization of cables within commercial trucks. Its role is significant in maintaining the structural integrity and operational efficiency of the vehicle’s electrical systems.

Basic Concepts of Cable Brackets

Cable brackets are fixtures used in vehicles to hold and guide cables, ensuring they are properly positioned and protected. These brackets contribute to the overall structural integrity of a truck by preventing cable tangling and damage, which can lead to electrical failures. They also enhance operational efficiency by ensuring cables are routed in a manner that minimizes interference with other components and reduces the risk of wear and tear 1.

Purpose of the Cummins 4001004 Cable Bracket

This Cummins part is specifically designed to secure and route cables within a truck’s electrical system. It plays a role in maintaining the organization of cables, which is vital for the proper functioning of electrical components. By securing cables in place, it helps prevent them from coming into contact with moving parts or sharp edges, which could cause damage or malfunction.

Key Features

The 4001004 is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features such as mounting points and cable guides, which facilitate easy installation and effective cable management. The bracket’s unique characteristics, such as its corrosion-resistant coating, enhance its performance and longevity in various operating conditions 2.

Benefits

This part offers several benefits, including improved cable management, which leads to a more organized and efficient electrical system. Its enhanced durability ensures long-term reliability, reducing the need for frequent replacements. Additionally, by securing cables effectively, it contributes to the overall reliability of the truck’s electrical system, minimizing the risk of electrical failures.

Installation Process

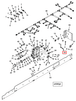

Installing the Cable Bracket involves several steps to ensure proper placement and function. First, identify the correct location for the bracket based on the truck’s design and the cable routing requirements. Use the appropriate tools to secure the bracket in place, ensuring it is firmly attached to prevent movement. Finally, route the cables through the bracket, making sure they are properly guided and secured to avoid any potential damage or interference.

Troubleshooting Common Issues

Common problems associated with cable brackets include loose connections and wear and tear. To address these issues, regularly inspect the bracket and cables for signs of damage or wear. Tighten any loose connections and replace worn or damaged components as necessary to maintain the integrity of the electrical system 3.

Maintenance Tips

To prolong the life of the 4001004, incorporate regular maintenance practices into your routine. This includes inspecting the bracket and cables for signs of wear, ensuring all connections are secure, and cleaning the bracket to remove any dirt or debris that could affect its performance. Regular maintenance helps prevent issues before they become significant problems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components designed to enhance the performance and reliability of commercial vehicles, reflecting its dedication to excellence and customer satisfaction.

Compatibility with Cummins Engines

This part is designed to be compatible with a range of Cummins engines. Specifically, this part fits seamlessly with the following engines:

- QSK45 CM500

- QSK60 CM500

- QSK60G

This bracket is engineered to provide a secure mounting point for cables, ensuring they remain properly aligned and protected within the engine compartment. The design of the bracket allows for easy installation and adjustment, accommodating the unique layout and requirements of each engine model.

For the QSK45 CM500 and QSK60 CM500, the bracket’s placement is critical in maintaining the integrity of the engine’s electrical and control systems. Similarly, for the QSK60G, the bracket ensures that all cables are managed efficiently, reducing the risk of wear and damage due to movement or vibration.

By using the 4001004, technicians and operators can ensure that their engines maintain optimal performance and reliability, as the bracket plays a key role in the overall organization and functionality of the engine’s cable management system.

Role of Part 4001004 Cable Bracket in Engine Systems

The 4001004 is an essential component in the integration and secure mounting of various cables within engine systems. It facilitates the organized routing of cables from the Engine Control Module (ECM) to other critical components, ensuring that signal transmission remains unimpeded and reliable.

In engine systems, the Cable Bracket supports the cables that connect the ECM to sensors, actuators, and other control units. This secure mounting prevents cable fatigue and damage, which can otherwise lead to signal loss or erratic engine performance.

Additionally, the bracket plays a significant role in maintaining the structural integrity of the cable network. By providing a stable attachment point, it reduces the risk of cables becoming dislodged during engine operation, which is particularly important in high-vibration environments typical of engine compartments.

The organized routing afforded by the Cable Bracket also aids in thermal management. It ensures that cables are positioned away from high-temperature zones, reducing the risk of insulation degradation and maintaining the efficiency of signal transmission.

Furthermore, the bracket contributes to the overall modularity of the engine system. It allows for easier access to cables during maintenance or upgrades, simplifying the process of diagnosing and rectifying issues related to the engine control system.

Conclusion

In summary, the 4001004 Cable Bracket is integral to the reliable operation of engine systems by securing and organizing cables, enhancing durability, aiding in thermal management, and supporting system modularity.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Klyde, Michael and VanGelder, Kirk. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Genta, Giancarlo and Morello, Lorenzo. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.