This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

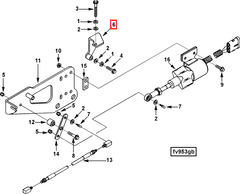

The Cable Bracket 3924430 is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This bracket is designed to facilitate the secure mounting and organization of cables within commercial truck operations. Its role is significant in maintaining the structural integrity and operational efficiency of the vehicle’s electrical systems 1.

Purpose and Function

The Cable Bracket 3924430 serves to anchor and route cables in a manner that minimizes interference with other components and reduces the risk of damage from vibrations or harsh environmental conditions. It integrates seamlessly with the truck’s electrical system, ensuring that cables are held firmly in place while allowing for necessary adjustments and maintenance 2.

Key Features

The design of the Cable Bracket 3924430 incorporates durable materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. It offers versatile mounting options, allowing it to be secured in various positions depending on the truck’s layout. Unique attributes such as its robust construction and ease of installation contribute to its reliable performance 3.

Benefits

Utilizing the Cable Bracket 3924430 provides several advantages. It enhances cable management by keeping wires organized and protected, which can lead to improved system reliability. The bracket’s durable construction contributes to the overall longevity of the truck’s electrical components. Additionally, by preventing cable damage, it may offer cost savings for fleet operators through reduced repair and replacement needs 4.

Installation Process

Installing the Cable Bracket 3924430 involves securing it to the truck’s frame using the appropriate fasteners. It is important to follow the manufacturer’s guidelines for placement to ensure optimal cable routing and protection. Tools required may include a drill, wrenches, and possibly a torque wrench to ensure fasteners are tightened to the correct specifications. Careful planning and execution during installation will result in a secure and effective mounting solution 5.

Maintenance and Troubleshooting

Regular inspection of the Cable Bracket 3924430 is recommended to ensure it remains in good condition and that cables are not compromised. Common issues may include loose fasteners or cable abrasion, which can be addressed by tightening components or adjusting cable routing. Prompt attention to these matters will help maintain the integrity of the electrical system 6.

Safety Considerations

When working with the Cable Bracket 3924430, it is important to observe safety protocols to protect both mechanics and operators. This includes ensuring the truck is properly grounded during electrical work, using the correct tools and personal protective equipment, and following all manufacturer guidelines to prevent accidents and ensure the component functions as intended 7.

Cummins Overview

Cummins is a reputable manufacturer with a long-standing history in the automotive industry. Known for their commitment to quality and innovation, Cummins produces a wide range of components that are designed to meet the rigorous demands of commercial and heavy-duty applications. Their products are engineered to deliver reliable performance and are backed by a reputation for excellence in the field 8.

Application with Cummins Engines

The Cable Bracket 3924430 is compatible with several Cummins engine models, including but not limited to:

- 6B5.9: This engine variant benefits from the precise fit and robust construction of the 3924430 bracket. It ensures that the cables are held firmly in place, reducing the risk of wear and tear, and maintaining the integrity of the engine’s electrical system.

The design of the bracket allows for easy installation and adjustment, making it a versatile solution for various engine configurations. Its placement is crucial for maintaining the functionality and reliability of the engine’s electrical and control systems 9.

Role of Part 3924430 Cable Bracket in Engine Systems

The 3924430 Cable Bracket is an integral component in the orchestration of various engine systems, ensuring the seamless operation of critical functions. It primarily serves as a secure mounting point for the cable that connects the Valve to the Fuel Shutoff mechanism.

When the Valve is actuated, either manually or automatically, the movement is transmitted through the cable to the Fuel Shutoff. The Cable Bracket ensures that this transmission is efficient and without undue strain on the cable. It provides a stable and vibration-resistant attachment point, which is essential given the dynamic environment of an engine compartment.

Moreover, the Cable Bracket’s positioning allows for optimal cable routing, minimizing the risk of abrasion or interference with other engine components. This careful routing is vital for maintaining the integrity of the cable and ensuring consistent operation of the Fuel Shutoff 10.

Conclusion

In summary, the 3924430 Cable Bracket plays a significant role in maintaining the structural and functional integrity of the cable system that connects the Valve to the Fuel Shutoff, contributing to the reliable performance of the engine system. Its durable construction, ease of installation, and versatile application make it a valuable component for Cummins engine systems.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358453.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.