This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

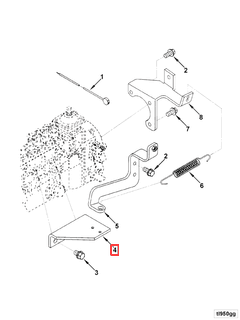

The Cummins 3922862 Cable Bracket is a component designed to support and secure cables within commercial trucks. Its role is significant in maintaining the structural integrity and operational efficiency of the vehicle. This bracket ensures that cables are properly managed, reducing the risk of damage and enhancing the overall performance of the truck 1.

Basic Concepts of Cable Brackets

Cable brackets are components used in vehicles to hold and organize cables. They play a role in maintaining the structural integrity of the vehicle by securing cables in place, preventing them from moving or becoming damaged. In trucks, cable brackets contribute to operational efficiency by ensuring that cables are properly managed, which can help prevent electrical issues and improve the reliability of the vehicle 2.

Purpose of the Cummins 3922862 Cable Bracket

The Cummins 3922862 Cable Bracket is specifically designed to support and secure cables in commercial trucks. It plays a role in the truck’s operation by providing a stable attachment point for cables, which helps in managing cable routing and reducing the risk of cable damage. This bracket ensures that cables remain in their intended positions, contributing to the overall safety and efficiency of the truck 3.

Key Features

The Cummins 3922862 Cable Bracket is constructed from durable materials, ensuring it can withstand the rigors of commercial truck environments. Its design includes features such as precise mounting points and robust construction, which enhance its performance and durability. These characteristics ensure that the bracket can effectively support and secure cables over time 4.

Benefits

The Cummins 3922862 Cable Bracket offers several benefits, including improved cable management. By securely holding cables in place, it reduces the likelihood of cable damage and enhances the safety of the truck’s electrical system. Additionally, the bracket contributes to the longevity of cable systems by preventing wear and tear, ensuring that cables remain functional and reliable 5.

Installation Process

Installing the Cummins 3922862 Cable Bracket involves several steps to ensure proper attachment and functionality. Begin by identifying the correct location for the bracket on the truck. Use the provided mounting hardware to secure the bracket in place, ensuring that it is firmly attached. Route the cables through the bracket, making sure they are properly supported and not under tension. Finally, double-check all connections to ensure they are secure and the bracket is correctly installed 6.

Troubleshooting and Maintenance

Common issues with the Cummins 3922862 Cable Bracket may include loose connections or damaged brackets. To troubleshoot, inspect the bracket and its attachments regularly for signs of wear or damage. Ensure that cables are not frayed or pinched, and that the bracket remains securely mounted. Regular maintenance, such as tightening connections and checking for corrosion, can help ensure optimal performance and longevity 7.

Common Applications

The Cummins 3922862 Cable Bracket is commonly used in various types of commercial trucks, including those equipped with Cummins engines. It is particularly useful in trucks where cable management is critical for operational efficiency and safety. Specific models and configurations may vary, but the bracket is designed to be versatile and compatible with a range of truck applications 8.

Safety Considerations

When installing and maintaining the Cummins 3922862 Cable Bracket, it is important to consider safety. Ensure that the bracket is properly secured to prevent it from becoming a hazard. Handle cables carefully to avoid damage, and conduct regular inspections to identify any potential issues. Secure attachments and regular maintenance are key to ensuring the bracket performs its function safely and effectively 9.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and commitment to innovation. The company’s extensive product range and focus on customer satisfaction make it a trusted name in the industry 10.

Compatibility with Cummins Engines

The Cable Bracket 3922862, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for securing and routing cables within the engine compartment, ensuring that electrical connections remain stable and reliable.

6C8.3

The 6C8.3 engine benefits from the Cable Bracket 3922862, which helps in maintaining the integrity of the electrical system by providing a secure mounting point for cables. This bracket ensures that cables are properly aligned and protected from potential damage due to engine vibrations or movement.

ISC CM850

In the ISC CM850 engine, the Cable Bracket 3922862 plays a vital role in organizing and securing the engine’s electrical cables. Its design allows for efficient cable management, which is essential for the smooth operation of the engine’s electronic control systems.

ISL9 CM2150 SN

For the ISL9 CM2150 SN engine, the Cable Bracket 3922862 is integral to the engine’s electrical infrastructure. It provides a robust mounting solution that ensures cables are kept in place, reducing the risk of disconnections or damage that could lead to operational issues.

QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine also utilizes the Cable Bracket 3922862. This bracket is essential for maintaining the structural integrity of the engine’s electrical system, ensuring that all cables are securely fastened and properly routed to prevent interference with other engine components.

QSL9 CM850 (CM2850)

Similar to the QSC8.3 CM850 (CM2850), the QSL9 CM850 (CM2850) engine incorporates the Cable Bracket 3922862 to manage and secure its electrical cables. This part is crucial for ensuring that the engine’s electrical system operates efficiently and reliably, with all cables properly positioned and protected.

Role of Part 3922862 Cable Bracket in Engine Systems

The part 3922862 Cable Bracket is an essential component in the assembly and operation of various engine systems. It provides a secure mounting point for the cable that connects the throttle lever to the water pump in manual engine control systems.

Integration with Drive and Water Pump

In engine systems, the drive mechanism is responsible for transferring power from the engine to other components. The water pump, a key component in cooling systems, ensures that coolant circulates effectively to maintain optimal engine temperature. The Cable Bracket plays a significant role here by securing the cable that links the throttle lever to the water pump. This connection allows for precise control over the water pump’s operation, ensuring it responds accurately to the throttle settings.

Connection to Throttle Lever

The throttle lever is a pivotal part of the manual engine control system, allowing the operator to adjust the engine’s power output. The Cable Bracket ensures that the cable connecting the throttle lever to the water pump remains taut and aligned. This alignment is vital for the lever to transmit the operator’s inputs effectively to the water pump, thereby controlling the flow of coolant and, consequently, the engine’s cooling efficiency.

Ensuring Stability and Precision

By providing a stable mounting point, the Cable Bracket helps maintain the integrity of the cable’s path. This stability is essential for the consistent and accurate transmission of force from the throttle lever to the water pump. Without a secure mounting, the cable could become misaligned or slack, leading to inefficient engine performance and potential overheating.

Enhancing Manual Engine Control System Performance

In manual engine control systems, the precision of component interactions is paramount. The Cable Bracket contributes to this precision by ensuring that the cable remains in the correct position and under the appropriate tension. This setup allows for smooth and responsive control over the engine’s cooling system, enhancing overall engine performance and reliability.

Conclusion

The Cummins 3922862 Cable Bracket is a critical component in the maintenance and operation of commercial trucks and various Cummins engines. Its role in securing and organizing cables ensures the structural integrity and operational efficiency of the vehicle. By providing a stable mounting point for cables, this part enhances the safety and reliability of the truck’s electrical system, contributing to the overall performance and longevity of the vehicle.

-

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022

↩ -

The Complete Vehicle, Michael Trzesniowski, Springer Nature, 2023

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022

↩ -

The Complete Vehicle, Michael Trzesniowski, Springer Nature, 2023

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022

↩ -

The Complete Vehicle, Michael Trzesniowski, Springer Nature, 2023

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.