This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

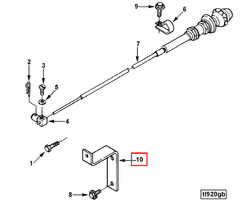

The Cummins 3919871 Cable Bracket is a component designed for use in commercial trucks. It serves to secure and organize various cables within the vehicle, ensuring they are properly managed and protected. This part plays a significant role in maintaining the integrity and functionality of the truck’s electrical systems 1.

Purpose and Function

The primary role of the Cable Bracket is to secure and organize cables within the truck. By providing a structured environment for cables, it helps prevent them from becoming tangled or damaged. This organization is vital for the proper functioning of the truck’s electrical systems, ensuring that signals and power are transmitted efficiently and reliably 2.

Key Features

This Cummins part is constructed from durable materials, designed to withstand the rigors of commercial truck environments. Its design includes features that allow for easy cable routing and secure attachment, ensuring that cables remain in place even under vibration and movement. The bracket’s construction is robust, providing long-lasting performance and reliability 3.

Benefits

Using the 3919871 offers several benefits. It improves cable management by providing a designated space for cables, reducing the risk of tangling and damage. This organized approach enhances the safety and reliability of the truck’s electrical systems. Additionally, by securing cables, the bracket helps protect them from physical damage, extending their lifespan and ensuring consistent performance 4.

Installation and Usage

Proper installation of the 3919871 involves securing it in the designated location within the truck. This process may require specific tools, such as wrenches or screwdrivers, depending on the truck’s design. Once installed, cables can be routed through the bracket, ensuring they are organized and protected. It is important to follow the manufacturer’s guidelines for installation to ensure optimal performance and safety 5.

Troubleshooting and Maintenance

Common issues with the 3919871 may include loose connections or cable damage. Regular inspection and maintenance can help identify and address these issues promptly. Ensuring that cables are properly secured and not showing signs of wear or damage is crucial. Additionally, cleaning the bracket and surrounding area can prevent debris from affecting its performance 6.

Cummins Overview

Cummins is a well-established company in the commercial truck industry, known for its high-quality engines and components. With a history of innovation and reliability, Cummins offers a wide range of products designed to enhance the performance and efficiency of commercial vehicles. The company’s reputation for quality and durability is reflected in its product offerings, including the 3919871 7.

Role of 3919871 in Engine Systems

In the orchestration of engine systems, the 3919871 assumes a significant role by providing a secure mounting point for various cables integral to engine operation. This part is instrumental in maintaining the structural integrity and precise alignment of cables, which are essential for the reliable function of components such as the lever and throttle 8.

Integration with the Lever

The lever, a pivotal component in engine systems, relies on the 3919871 to ensure that the connecting cables are held firmly in place. This bracket allows for the adjustment and maintenance of cable tension, which is vital for the lever’s responsive operation. Whether it’s for shifting gears in a transmission system or actuating other mechanical functions, the bracket’s role in supporting the lever’s cable is indispensable 9.

Contribution to Throttle Operation

Throttle control is another area where the 3919871 plays a part. The throttle, which regulates the amount of fuel and air entering the engine, is often connected via a cable system. The bracket ensures that this cable remains taut and correctly aligned, facilitating smooth and accurate throttle responses. This is particularly important in maintaining engine performance and fuel efficiency, as any slack or misalignment in the cable could lead to inconsistent throttle operation 10.

Conclusion

In summary, the 3919871 is a key component in the engine system’s cable management, supporting the functionality of the lever and throttle by providing a stable and adjustable mounting solution for cables. Its design and placement are tailored to enhance the precision and reliability of engine operations.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.