This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5371000 Crankcase Breather is a component designed to facilitate the proper ventilation of the crankcase in heavy-duty trucks. Its role is significant in maintaining the engine’s operational efficiency and longevity. This breather system is engineered to manage the pressure and contaminants within the crankcase, ensuring the engine operates under optimal conditions.

Basic Concepts of Crankcase Breathers

A crankcase breather is a device that allows air to escape from the crankcase of an engine. As the engine operates, it produces gases and vapors that need to be expelled to prevent pressure buildup and contamination. Proper ventilation is vital for the engine’s health, as it helps in maintaining a stable environment within the crankcase, which is crucial for the lubrication system and overall engine performance 1.

Purpose of the Cummins 5371000 Crankcase Breather

This Cummins part is specifically designed to address the ventilation needs of heavy-duty truck engines. It plays a role in managing the pressure and contaminants within the crankcase by allowing the escape of gases and vapors produced during engine operation. This helps in maintaining a balanced pressure within the crankcase, which is important for the efficient operation of the engine 2.

Key Features

The 5371000 is constructed with materials that ensure durability and efficiency. Its design includes filtration capabilities that help in trapping contaminants before they can re-enter the engine, thus contributing to the cleanliness of the crankcase environment. Unique design elements may include a robust housing and a filtration system that is tailored to the demanding conditions under which heavy-duty trucks operate 3.

Benefits

The use of the 5371000 can lead to improved engine performance by ensuring that the crankcase remains free of excessive pressure and contaminants. This can result in reduced wear on engine components, as the lubrication system operates more effectively in a clean and stable environment. Additionally, the breather contributes to the enhanced longevity of the engine by maintaining optimal conditions within the crankcase 4.

Installation and Compatibility

Proper installation of the 5371000 is important to ensure it functions as intended. Specific requirements or considerations may vary depending on the truck model, and it is important to follow manufacturer guidelines to ensure compatibility and correct fitting. This ensures that the breather system integrates seamlessly with the engine’s ventilation system.

Maintenance and Troubleshooting

Regular maintenance of the 5371000 is important to ensure its optimal performance. This includes inspection intervals to check for any signs of wear or damage, and cleaning procedures to maintain the filtration system’s efficiency. Common issues that may arise include blockages or leaks, and troubleshooting steps may involve cleaning or replacing components as necessary.

Environmental and Safety Considerations

The 5371000 contributes to reducing emissions by ensuring that the crankcase ventilation system operates efficiently, which can help in minimizing the release of harmful gases. Additionally, by maintaining a stable environment within the engine compartment, it enhances safety by reducing the risk of pressure-related issues that could lead to engine damage.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a history of producing diesel engines and related components. The company is known for its commitment to quality and innovation, which is reflected in its product line, including the 5371000. Cummins’ reputation in the industry is built on its ability to deliver reliable and efficient solutions for heavy-duty applications.

Crankcase Breather Part 5371000 Compatibility with Cummins Engines

This part is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. It is engineered to manage the pressure within the engine’s crankcase, preventing oil contamination and ensuring the engine operates efficiently.

ISG12 G CMOH6.0 G111, Z14 CM2670 Z103B

The 5371000 is compatible with the ISG12 G CMOH6.0 G111 engine. This compatibility ensures that the breather effectively handles the pressure variations within the engine’s crankcase, maintaining the integrity of the engine’s oil system and preventing oil leaks.

Similarly, the Z14 CM2670 Z103B engine also benefits from the use of the 5371000. This part is specifically designed to fit the unique requirements of this engine model, ensuring that it operates smoothly and efficiently.

By integrating the 5371000 into these engines, users can expect enhanced engine performance, reduced maintenance needs, and improved overall reliability. This compatibility underscores Cummins’ commitment to providing high-quality components that meet the demands of their diverse engine lineup.

Understanding the Integration of Part 5371000 Crankcase Breather in Engine Systems

The 5371000 is an essential component that works in conjunction with several key elements within an engine system to maintain optimal performance and longevity. Its primary function is to manage the pressure within the crankcase by allowing gases to escape, thus preventing the buildup of harmful contaminants.

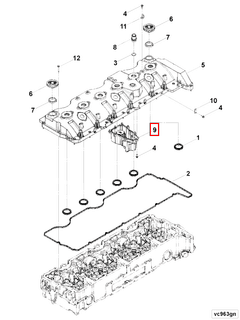

Interaction with the Valve Cover

The Crankcase Breather is typically mounted on the valve cover, forming a sealed connection. This arrangement ensures that any gases expelled from the crankcase are directed away from the engine’s internal components. The valve cover itself is designed to protect the valve train and other upper engine components from external contaminants while maintaining a sealed environment.

Role in the Valve Cover Arrangement

In a valve cover arrangement, the Crankcase Breather plays a significant role by providing a pathway for gases to exit the crankcase. This is particularly important in systems where positive crankcase ventilation (PCV) is employed. The breather helps in regulating the flow of these gases, ensuring that they are either recirculated back into the intake system or expelled from the engine bay, depending on the specific design of the PCV system.

The effective integration of the Crankcase Breather with the valve cover and the overall valve cover arrangement is vital for maintaining engine health. It helps in reducing the accumulation of sludge and other deposits within the crankcase, which can otherwise lead to increased wear on moving parts and potentially catastrophic engine failure.

By facilitating the proper ventilation of the crankcase, the Crankcase Breather contributes to a more stable and efficient engine operation, ensuring that the engine runs smoothly and reliably over its service life.

Conclusion

The Cummins 5371000 Crankcase Breather is a vital component for maintaining the health and efficiency of heavy-duty truck engines. Its role in managing crankcase pressure and contaminants ensures optimal engine performance and longevity. Proper installation, maintenance, and understanding of its integration within engine systems are key to maximizing the benefits of this part.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Taghavifar, Hamid and Mardani, Aref. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Han, Zhiyu. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.