This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4101350 Crankcase Breather is a component designed to facilitate the efficient operation of heavy-duty truck engines. Its purpose is to manage the pressure within the crankcase and to expel contaminants, thereby contributing to the overall health and performance of the engine.

Basic Concepts of Crankcase Breather

A crankcase breather is a component in an engine’s ventilation system. Its primary function is to allow gases produced during the combustion process to escape from the crankcase. This process helps maintain a balanced pressure within the crankcase, preventing the buildup of harmful gases and moisture that could otherwise lead to engine damage. The breather operates by venting these gases to the atmosphere or recirculating them back into the intake system, depending on the design 1.

Purpose of the 4101350 Crankcase Breather

This Cummins part plays a role in the operation of a truck by managing the pressure within the crankcase. It expels contaminants such as moisture and unburned fuel that accumulate during engine operation. By doing so, it helps to maintain a clean and dry environment within the crankcase, which is vital for the longevity and efficiency of the engine.

Key Features

The design and construction of the 4101350 incorporate several features that enhance its performance. It is constructed from durable materials to withstand the harsh conditions within the engine compartment. The breather includes filtration capabilities to trap particles and prevent them from re-entering the engine. Additionally, it may feature unique attributes such as a check valve to prevent backflow and a baffle system to separate oil from the gases.

Benefits

Utilizing the 4101350 offers several advantages. It contributes to improved engine performance by ensuring that the crankcase remains free from contaminants. This can lead to extended engine life, as the breather helps to prevent the buildup of sludge and other deposits that can cause wear and tear. Furthermore, it reduces maintenance requirements by minimizing the need for frequent oil changes and component replacements 2.

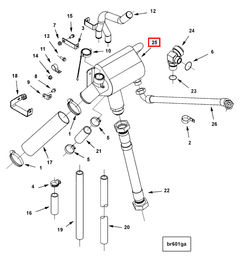

Installation Process

Installing the 4101350 involves several steps to ensure proper function. The process requires specific tools, such as wrenches and possibly a torque wrench, to secure the breather in place. It is important to follow the manufacturer’s instructions carefully, ensuring that all connections are tight and that the breather is correctly oriented. Attention to detail during installation is crucial to avoid leaks and ensure optimal performance.

Maintenance Tips

Regular maintenance of the 4101350 is important to ensure its continued effectiveness. This includes periodic inspection to check for signs of wear or damage. Cleaning the breather according to the manufacturer’s recommendations can help maintain its filtration capabilities. It is also advisable to follow the suggested inspection intervals to catch any potential issues early.

Troubleshooting Common Issues

Common problems associated with crankcase breathers can include leaks, blockages, or reduced efficiency. Troubleshooting these issues may involve checking for loose connections, inspecting the breather for damage, or cleaning the filtration system. Addressing these problems promptly can help maintain engine performance and prevent more serious issues from developing.

Regulatory Compliance

The 4101350 complies with industry standards and regulations, ensuring it meets safety and performance requirements. This compliance is important for maintaining the integrity of the engine and ensuring that the breather operates within the parameters set by automotive authorities.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a commitment to quality, Cummins offers a comprehensive product range that includes engines, filtration, emissions solutions, and power generation technologies. The company’s dedication to advancing technology and improving efficiency is evident in its diverse portfolio of products designed for various industries, including transportation, construction, and power generation.

Engine Compatibility

The Crankcase Breather part 4101350 is compatible with the following Cummins engines:

- QSK45

- CM500

These engines are known for their robust design and are widely used in various industrial and commercial applications, including power generation, marine, and heavy-duty transportation. The breather part is specifically tailored to fit these engines, ensuring a precise and reliable seal that maintains the integrity of the crankcase environment 3.

Installation and Functionality

When installed, the Crankcase Breather part 4101350 connects to the engine’s crankcase ventilation system. It allows for the controlled release of gases and vapors, preventing pressure build-up while simultaneously keeping contaminants out. This functionality is crucial for maintaining the health of the engine, as it helps to reduce wear and tear on internal components.

Importance in Engine Maintenance

Regular maintenance and timely replacement of the Crankcase Breather part 4101350 are essential for the longevity and performance of the engines it supports. Ensuring that this part is in good condition helps to maintain the overall efficiency of the engine, preventing potential issues that could arise from a malfunctioning breather system.

Conclusion

The 4101350 Crankcase Breather is a key component in the engine system, ensuring the proper functioning of the Positive Crankcase Ventilation (PCV) system, maintaining oil quality, and contributing to the engine’s overall efficiency and emission control. By integrating this part into the engine’s design, Cummins ensures that the engines operate smoothly and efficiently, providing reliable performance in demanding environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.