This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3235123 Crankcase Breather is a component designed to facilitate the proper ventilation of the crankcase in heavy-duty truck engines. Its role is significant as it helps maintain the engine’s internal environment, ensuring optimal performance and longevity.

Basic Concepts of Crankcase Breathers

A crankcase breather is a device that allows air to escape from the crankcase as the engine operates. This is important because as the pistons move, they create pressure within the crankcase, which can lead to the formation of blow-by gases—a mixture of air, fuel, and combustion byproducts. The breather system helps to vent these gases, preventing pressure build-up that could lead to oil leaks and other engine issues. Proper ventilation is crucial for maintaining engine health and efficiency 1.

Purpose and Role in Truck Operation

The Cummins 3235123 Crankcase Breather is specifically engineered to address the ventilation needs of heavy-duty truck engines. By allowing the escape of blow-by gases, it helps to maintain a stable pressure within the crankcase. This contributes to consistent engine performance and reduces the risk of oil contamination. Additionally, it plays a role in minimizing oil consumption by preventing the dilution of oil with blow-by gases, which can degrade oil quality and reduce its lubricating effectiveness 2.

Key Features

The Cummins 3235123 Crankcase Breather is characterized by its robust design and high-quality materials. It is constructed to withstand the harsh conditions typical of heavy-duty truck operations. The breather includes filtration elements that capture contaminants from the expelled gases, ensuring that only clean air re-enters the engine. Its design also incorporates features that enhance its durability and reliability in demanding environments.

Benefits

The use of the Cummins 3235123 Crankcase Breather offers several advantages. It contributes to improved engine efficiency by maintaining optimal crankcase pressure and oil quality. Reduced emissions are another benefit, as the breather helps to capture and redirect harmful gases, minimizing their release into the atmosphere. Additionally, the breather enhances engine durability by preventing oil contamination and reducing wear on engine components 3.

Troubleshooting and Maintenance

Common issues with crankcase breathers include clogging and leaks. Regular inspection and maintenance are recommended to ensure the breather operates effectively. Diagnostic procedures may involve checking for signs of oil leaks, assessing the breather’s filtration efficiency, and ensuring there is no obstruction in the ventilation path. Maintenance practices include cleaning or replacing the breather as necessary to maintain its functionality.

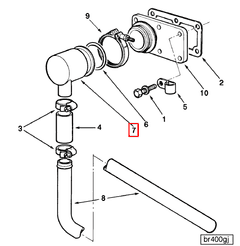

Installation Considerations

Proper installation of the Cummins 3235123 Crankcase Breather is vital for its effective operation. Installation procedures should follow manufacturer guidelines, including torque specifications for securing the breather in place and ensuring proper sealing to prevent leaks. Compatibility with various engine configurations should be verified to ensure optimal performance and integration within the engine system.

Performance Impact

The Cummins 3235123 Crankcase Breather influences engine performance in several ways. By regulating crankcase pressure, it helps to maintain consistent oil levels and quality, which is crucial for engine lubrication. This can lead to reduced oil consumption and lower emissions. Additionally, the breather contributes to overall engine reliability by preventing issues related to pressure build-up and oil contamination.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a history of innovation and a strong reputation in the automotive industry, Cummins is known for producing high-quality components that enhance the performance and reliability of vehicles, particularly in heavy-duty applications.

Compatibility with Cummins Engines

The Cummins BREATHER,CRANKCASE part number 3235123 is designed to fit seamlessly with various Cummins engines. This part is engineered to ensure proper ventilation and pressure management within the engine’s crankcase, which is essential for maintaining optimal engine performance and longevity.

K19 Engine Family

The BREATHER,CRANKCASE part 3235123 is specifically designed to integrate with the K19 engine family. This family of engines is known for its robust construction and reliability, making it a popular choice in various industrial and commercial applications. The K19 engines benefit from the precise fit and functionality of the 3235123 part, ensuring that the crankcase is properly ventilated and pressure is managed effectively.

The compatibility of this part with the K19 engines is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and durability. By ensuring that the BREATHER,CRANKCASE part fits perfectly with the K19 engines, Cummins guarantees that these engines can operate at peak efficiency, reducing the risk of damage and extending the overall lifespan of the engine.

Understanding the Role of Part 3235123 BREATHER,CRANKCASE in Engine Systems

In the realm of engine systems, the part 3235123 BREATHER,CRANKCASE is an essential component that facilitates the efficient operation of the crankcase breather system. This component is strategically positioned to manage the pressure within the crankcase, ensuring that the engine operates smoothly and efficiently.

Integration with Crankcase Breather System

The crankcase breather system is designed to release built-up gases and vapors from the crankcase, which are byproducts of the combustion process. Part 3235123 plays a significant role in this system by allowing these gases to escape while preventing external contaminants from entering the crankcase. This balance is vital for maintaining the integrity of the engine oil and ensuring optimal engine performance.

Interaction with Breather Location

The effectiveness of part 3235123 is highly dependent on its precise location within the engine system. Typically, this component is installed at a point where it can efficiently vent gases while being shielded from direct exposure to the elements. The breather location is carefully chosen to maximize airflow and minimize the risk of contamination. This strategic placement ensures that the crankcase remains pressurized at an optimal level, which is essential for the proper functioning of the piston rings and overall engine efficiency.

Contribution to Engine Health

By integrating part 3235123 into the crankcase breather system, engineers and mechanics can significantly enhance engine health. The component helps in reducing the accumulation of sludge and moisture within the crankcase, which are common issues that can lead to decreased engine performance and increased wear on internal components. Additionally, it aids in maintaining a consistent oil level, which is critical for lubrication and cooling within the engine.

Enhanced System Performance

The presence of part 3235123 in the breather system contributes to the overall performance of the engine. By ensuring that the crankcase remains free from excessive pressure and contamination, this component allows the engine to operate more efficiently. This results in better fuel economy, reduced emissions, and prolonged engine life. Furthermore, it supports the maintenance of proper oil viscosity, which is essential for the lubrication of moving parts within the engine.

Conclusion

The Cummins 3235123 Crankcase Breather is a vital component in the engine system, playing a key role in the crankcase breather system. Its proper integration and strategic placement are essential for maintaining engine health, enhancing performance, and ensuring the longevity of the engine.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Konrad Reif Ed. (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

MJ Nunney. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.