This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

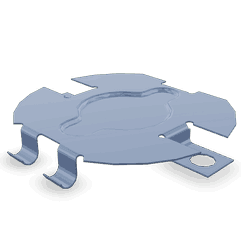

The Breather Baffle 3096430 is a component designed by Cummins for use in heavy-duty truck engines. Its purpose is to manage the airflow within the engine’s crankcase, ensuring optimal performance and longevity of the engine. This part is significant in heavy-duty truck operations as it contributes to maintaining engine efficiency and reducing the need for frequent maintenance.

Basic Concepts

A breather baffle is a device that regulates the flow of air within an engine’s crankcase. It operates on the principle of allowing air to enter and exit the crankcase while preventing the escape of oil vapors and contaminants. This is achieved through a series of baffles and passages that direct the airflow in a controlled manner. The Breather Baffle 3096430 functions within this context by providing a structured pathway for air to circulate, which helps in maintaining a clean and stable environment within the engine 1.

Purpose and Role

The Breather Baffle 3096430 plays a specific role in the operation of a truck by ensuring that the engine’s crankcase maintains an appropriate pressure balance. This balance is crucial for the efficient operation of the engine, as it prevents the buildup of pressure that could lead to oil leaks or other performance issues. Additionally, it helps in keeping the engine’s internal components clean by preventing the accumulation of contaminants, thereby contributing to the engine’s longevity 2.

Key Features

The Breather Baffle 3096430 is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. Its design includes multiple baffles that are strategically placed to optimize airflow and filtration. The materials used are resistant to the harsh conditions within the engine, ensuring that the baffle can withstand high temperatures and pressures. Additionally, the baffle may feature unique attributes such as enhanced filtration capabilities or improved sealing mechanisms that further enhance its performance.

Benefits

The installation of the Breather Baffle 3096430 offers several benefits. It contributes to improved engine performance by ensuring a stable crankcase environment, which allows the engine to operate more efficiently. Additionally, it reduces the need for frequent maintenance by preventing the buildup of contaminants and maintaining optimal pressure levels. The enhanced durability of the engine, due to the baffle’s protective role, also leads to longer service intervals and reduced overall maintenance costs.

Installation Process

Installing the Breather Baffle 3096430 requires careful attention to detail to ensure proper functionality. The process involves removing the old baffle, if present, and cleaning the installation area to ensure a secure fit. The new baffle is then positioned according to the manufacturer’s instructions, ensuring that all baffles and passages are correctly aligned. Tools required may include wrenches and sealant, and precautions should be taken to avoid damaging the baffle or the engine components during installation.

Common Issues and Troubleshooting

Common issues with the Breather Baffle 3096430 may include blockages in the baffle passages, which can lead to pressure imbalances within the crankcase. Troubleshooting involves inspecting the baffle for any signs of obstruction and cleaning or replacing it if necessary. Additionally, ensuring that the baffle is correctly installed and sealed can prevent issues related to air leaks or oil contamination.

Maintenance Tips

Regular maintenance of the Breather Baffle 3096430 is important to ensure its optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the baffle to remove any accumulated contaminants, and ensuring that all seals and connections are intact. Following the manufacturer’s recommended maintenance schedule will help in maintaining the efficiency and longevity of the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. The company’s product range includes a variety of engines and components designed for heavy-duty applications, demonstrating its commitment to meeting the needs of its customers with high-performance solutions.

Cummins Breather Baffle Part 3096430 in Engine Applications

The Cummins Breather Baffle part number 3096430 is a critical component in the engine systems of various Cummins engines, including the QSK19 CM500. This part plays a pivotal role in maintaining the integrity and efficiency of the engine’s crankcase ventilation system.

In the QSK19 CM500 engine, the breather baffle is designed to manage the flow of gases within the crankcase. It ensures that the crankcase pressure is maintained at an optimal level, preventing the escape of harmful gases into the environment while also avoiding the ingestion of contaminants back into the engine. This is achieved by directing the gases through specific pathways, thereby enhancing the overall performance and longevity of the engine.

The breather baffle is engineered to fit seamlessly within the engine’s architecture, ensuring that it integrates smoothly with other components. Its placement is crucial for effective ventilation and pressure management, which are essential for the engine’s operational efficiency. The design of the baffle allows it to withstand the high temperatures and pressures encountered within the engine, making it a durable and reliable component.

In the context of the QSK19 CM500 engine, the breather baffle is part of a comprehensive ventilation system that includes other components such as the PCV (Positive Crankcase Ventilation) valve and various hoses and ducts. These components work in unison to maintain the engine’s health and efficiency. The breather baffle’s role in this system is to ensure that the crankcase gases are properly managed, contributing to the engine’s overall performance and reliability.

The integration of the breather baffle in the QSK19 CM500 engine is a testament to Cummins’ commitment to quality and performance. By ensuring that this part fits perfectly within the engine’s design, Cummins guarantees that the engine operates at peak efficiency, with minimal environmental impact.

Role of Part 3096430 Breather Baffle in Engine Systems

The 3096430 Breather Baffle is an essential component in maintaining the efficiency and reliability of engine systems. It is strategically positioned within the valve cover arrangement to manage the airflow and pressure dynamics inside the engine.

Integration with Valve Cover Arrangement

In the valve cover arrangement, the Breather Baffle works in conjunction with the valve cover to regulate the ventilation of the crankcase. It ensures that any excess pressure or vacuum is effectively managed, preventing oil leaks and maintaining optimal engine performance. The baffle directs the flow of air and gases, allowing for efficient breathing of the engine while keeping contaminants at bay.

Function within the Valve Cover

Inside the valve cover, the Breather Baffle plays a pivotal role in separating the oil mist from the air. As the engine operates, it produces a mixture of air and oil vapor. The baffle helps in settling the oil droplets back into the sump, ensuring that the oil remains within the engine and does not escape through the ventilation system. This process is vital for maintaining proper lubrication and preventing oil loss.

Interaction with Valves

The Breather Baffle also indirectly affects the performance of the valves. By ensuring a clean and regulated airflow within the valve cover, it helps in maintaining a stable environment for the valves to operate. This stability is essential for the precise timing and sealing of the valves, which are critical for engine efficiency and longevity.

Overall Impact on Engine Systems

In summary, the 3096430 Breather Baffle is a key component in the engine’s ventilation system. Its proper function ensures that the engine breathes efficiently, maintains optimal pressure levels, and keeps the internal components clean and well-lubricated. This, in turn, contributes to the overall reliability and performance of the engine system.

Conclusion

The Breather Baffle 3096430 by Cummins is a critical component in the maintenance and efficiency of heavy-duty truck engines. By managing airflow within the crankcase, it ensures optimal engine performance, reduces maintenance needs, and contributes to the longevity of the engine. Its robust design, high-quality materials, and strategic placement within the engine system make it a reliable and essential part for any heavy-duty application.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.