This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

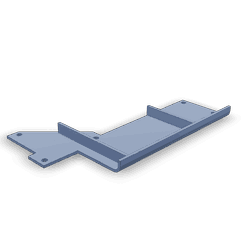

The Corrosion Resistor Bracket, part number 4913613, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is known for its commitment to innovation and quality. This bracket is significant in the context of truck operations, providing enhanced durability and resistance to environmental factors.

Purpose and Function

The Corrosion Resistor Bracket plays a role in supporting and securing various components within the truck’s engine system. It is typically positioned in areas exposed to harsh environmental conditions, such as moisture and chemicals, which can lead to corrosion. By providing a stable mounting point, it ensures that connected components remain securely in place, contributing to the overall efficiency and reliability of the truck’s operation.

Key Features

The design and material characteristics of the Corrosion Resistor Bracket are tailored to enhance its performance and durability. Constructed from high-grade materials, it exhibits strong resistance to corrosion, which is vital for components exposed to the elements. Its design includes features that facilitate easy installation and integration with other parts, ensuring a secure fit and long-lasting performance.

Benefits

Utilizing the Corrosion Resistor Bracket offers several advantages. Its robust construction contributes to improved longevity, reducing the frequency of replacements and associated costs. The bracket’s resistance to environmental factors minimizes the risk of corrosion-related failures, enhancing the truck’s reliability. Additionally, its design allows for ease of maintenance, making it a practical choice for fleet managers and technicians.

Installation Process

Installing the Corrosion Resistor Bracket involves several steps to ensure proper placement and functionality. Begin by identifying the correct location for the bracket, following the manufacturer’s guidelines. Use the appropriate tools to secure the bracket in place, ensuring it is firmly attached to the truck’s frame or designated mounting point. Verify that all connections are secure and that the bracket is aligned correctly with other components.

Maintenance and Troubleshooting

Regular maintenance of the Corrosion Resistor Bracket is important to ensure its continued performance. Inspect the bracket periodically for signs of wear or damage, and clean it as necessary to remove any buildup that could affect its function. Common issues may include loosening of the bracket or corrosion in surrounding areas. Addressing these problems promptly with the appropriate repairs or adjustments will help maintain the bracket’s effectiveness.

Environmental Considerations

The use of the Corrosion Resistor Bracket contributes to the environmental performance of the truck by reducing the incidence of corrosion-related failures. This not only extends the lifespan of the truck but also minimizes the need for frequent replacements, which can have environmental impacts. The bracket’s durability and resistance to corrosion play a role in supporting the overall sustainability of truck operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a pioneer in the automotive industry, known for its innovative solutions and commitment to quality. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to innovation and customer satisfaction underscores its position as a trusted partner in the automotive sector. 1

Cummins Corrosion Resistor Bracket 4913613 Compatibility

The Cummins Corrosion Resistor Bracket, part number 4913613, is a component designed to enhance the longevity and performance of various engine systems. This bracket is engineered to protect critical engine parts from corrosion, ensuring that the engine operates efficiently and reliably over time.

K19 Engine Series

The K19 engine series by Cummins is renowned for its robust design and exceptional performance in demanding applications. The Corrosion Resistor Bracket 4913613 is specifically designed to fit seamlessly within the architecture of the K19 engines. Its placement is crucial for safeguarding sensitive components from the detrimental effects of corrosion, which can otherwise lead to costly repairs and downtime.

Grouping of Compatible Engines

While the primary focus here is on the K19 engine series, it is important to note that the Corrosion Resistor Bracket 4913613 is also compatible with other Cummins engine models that share similar design characteristics and mounting points. This ensures that the bracket can be utilized across a broader range of Cummins engines, providing a standardized solution for corrosion protection.

By integrating the Corrosion Resistor Bracket 4913613 into the engine assembly, users can expect improved durability and reduced maintenance needs. This part is a testament to Cummins’ commitment to quality and reliability, ensuring that their engines remain in optimal condition for extended periods. 2

Role of Part 4913613 Corrosion Resistor Bracket in Engine Systems

The 4913613 Corrosion Resistor Bracket is integral to the structural and functional integrity of various engine systems. This component is designed to support and secure resistors within the engine assembly, ensuring they remain in optimal position and condition despite exposure to harsh environmental conditions.

In the context of the engine’s electrical system, the bracket plays a significant role in maintaining the stability of resistors, which are essential for regulating electrical current and voltage. By providing a corrosion-resistant mounting point, it prevents the degradation of the resistors due to moisture, chemicals, or other corrosive elements that can be present in engine compartments.

Additionally, the bracket contributes to the overall reliability of the engine’s performance. It ensures that the resistors are correctly aligned with other electrical components, such as sensors, control modules, and wiring harnesses. This alignment is vital for the precise operation of the engine’s electronic control systems, which rely on consistent and accurate electrical signals.

Furthermore, the use of a corrosion-resistant material in the bracket’s construction extends the lifespan of the resistors and the bracket itself. This durability is particularly important in engines that operate in demanding environments, such as those found in marine, industrial, or off-road applications, where exposure to salt, chemicals, and extreme temperatures is common.

In summary, the 4913613 Corrosion Resistor Bracket is a key component in ensuring the longevity and efficiency of the engine’s electrical systems by providing a secure, corrosion-resistant mounting solution for resistors. 3

Conclusion

The Corrosion Resistor Bracket 4913613 by Cummins is a vital component in the maintenance and efficiency of commercial truck engines. Its design and material properties ensure durability and resistance to corrosion, contributing to the overall reliability and sustainability of truck operations. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are essential for maximizing the benefits of this part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.