This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

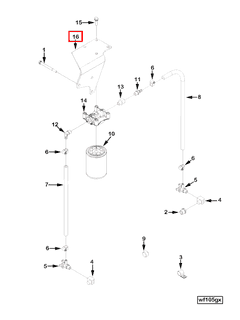

The Corrosion Resistor Bracket 3325493 by Cummins is a specialized component designed to enhance the durability and reliability of heavy-duty truck applications. This bracket is engineered to withstand harsh environmental conditions and mechanical stresses, ensuring long-term performance and safety in demanding operational environments 3.

Purpose and Function

The Corrosion Resistor Bracket 3325493 plays a role in the structural integrity of heavy-duty trucks by securing critical components in place. It is typically positioned in areas exposed to moisture, chemicals, and physical stress. By providing a stable mounting point, it ensures that connected parts remain securely fastened, which is vital for the overall functionality and safety of the vehicle 1.

Key Features

The design of the Corrosion Resistor Bracket 3325493 incorporates several key features that enhance its performance. Constructed from high-grade materials, it exhibits exceptional resistance to corrosion, which is crucial in environments where exposure to salt, chemicals, and moisture is common. Additionally, its robust design allows it to endure significant mechanical stress without deformation or failure 2.

Benefits

The advantages of using the Corrosion Resistor Bracket 3325493 include enhanced durability, improved safety, and reduced maintenance requirements. Its corrosion-resistant properties ensure a longer service life, minimizing the need for frequent replacements. Furthermore, by maintaining secure component placement, it contributes to the overall safety and reliability of the truck, reducing the risk of operational failures.

Installation Considerations

Proper installation of the Corrosion Resistor Bracket 3325493 is crucial for its effectiveness. It is recommended to follow manufacturer guidelines to ensure correct placement and secure fastening. Special tools may be required to achieve the proper torque specifications, ensuring that the bracket is installed correctly and functions as intended.

Maintenance and Troubleshooting

Routine maintenance practices for the Corrosion Resistor Bracket 3325493 include regular inspections for signs of wear, corrosion, or looseness. Ensuring that all fasteners are tight and that the bracket remains free of debris will help maintain its integrity. If any issues are detected, prompt corrective action should be taken to prevent further degradation.

Common Issues and Solutions

Typical problems that may arise with the Corrosion Resistor Bracket 3325493 include corrosion in harsh environments and mechanical wear from constant vibration. Solutions to these issues involve applying protective coatings to mitigate corrosion and ensuring that all fasteners are regularly checked and tightened to prevent loosening.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history of innovation and a strong reputation in the automotive industry, Cummins is known for producing high-quality, reliable products that meet the demanding needs of heavy-duty applications 3.

Compatibility

The Corrosion Resistor Bracket, part number 3325493, is designed to be compatible with a range of Cummins engines, ensuring robust protection against corrosion in various engine configurations. This bracket is integral to maintaining the structural integrity and longevity of the engine components, particularly in environments where corrosion is a significant concern.

NH/NT 855 Engines

The NH/NT 855 engines benefit from the installation of the 3325493 bracket. This bracket is engineered to secure specific components, preventing them from direct exposure to corrosive elements. Its placement is critical in areas where the engine is most susceptible to corrosion, ensuring that the engine’s operational efficiency and lifespan are preserved.

QSNT14 CM876 N102 Engines

For the QSNT14 CM876 N102 engines, the 3325493 bracket is equally essential. This engine model, known for its reliability and performance, requires precise engineering components to maintain its operational standards. The bracket’s role in these engines is to provide a stable mounting point that resists corrosion, thereby protecting the engine’s internal components from the damaging effects of moisture and other corrosive agents.

Grouping of Engines

The compatibility of the 3325493 bracket extends across various engine models, including but not limited to the NH/NT 855 and QSNT14 CM876 N102. This bracket is designed to fit seamlessly into the engine’s architecture, ensuring that it provides the necessary support and protection without requiring significant modifications to the engine’s design. Its universal fitment across different engine models underscores its versatility and importance in maintaining engine health and performance.

Role of Part 3325493 Corrosion Resistor Bracket in Engine Systems

The Corrosion Resistor Bracket (Part 3325493) is an essential component in various engine systems, providing a robust mounting solution for the Corrosion Resistor. This bracket ensures that the resistor is securely fastened, allowing it to function effectively within the engine’s electrical system.

In the context of engine systems, the Corrosion Resistor Mounting bracket plays a significant role in maintaining the integrity of the electrical connections. By resisting corrosion, it helps prevent electrical failures that could arise from corroded connections. This is particularly important in environments where the engine is exposed to moisture or other corrosive elements.

The Corrosion Resistor itself is designed to manage electrical resistance within the engine system. When mounted using the Corrosion Resistor Bracket, it ensures that the resistor remains in optimal condition, thereby contributing to the overall reliability of the engine’s electrical components.

Additionally, the bracket’s design allows for easy installation and maintenance, making it a practical choice for both engineers and mechanics. Its corrosion-resistant properties extend the lifespan of the mounted components, reducing the need for frequent replacements and repairs.

Conclusion

In summary, the Corrosion Resistor Bracket (Part 3325493) is a vital component that enhances the durability and performance of the engine’s electrical system by providing a secure and corrosion-resistant mounting solution for the Corrosion Resistor. Its robust design, compatibility with various Cummins engines, and ease of maintenance make it an indispensable part of heavy-duty truck applications.

-

Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, John Dixon, Cengage Learning, 2014

↩ -

Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.