This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

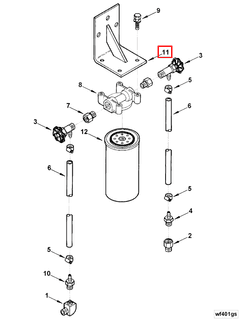

The Corrosion Resistor Bracket, part number 3047367, manufactured by Cummins, is a component designed for use in commercial trucks. It plays a role in protecting various truck components from the adverse effects of corrosion, which can be particularly problematic in heavy-duty applications. Corrosion resistance is vital in ensuring the longevity and reliability of truck components, especially those exposed to harsh environmental conditions 1.

Basic Concepts of Corrosion Resistor Brackets

Corrosion resistor brackets are designed to shield and support other components, reducing the impact of corrosive environments. These brackets are engineered based on principles of corrosion resistance, which involve selecting materials and designs that minimize the degradation caused by environmental factors such as moisture, chemicals, and temperature fluctuations. Common materials used in these brackets include stainless steel, galvanized steel, and various alloys known for their resistance to corrosion 2.

Purpose of the Corrosion Resistor Bracket

The Corrosion Resistor Bracket is specifically designed to support and protect components within a truck’s system. It plays a role in maintaining the structural integrity of attached parts and shielding them from environmental damage. By doing so, it helps in preserving the functionality and extending the lifespan of these components.

Key Features

This Cummins part boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that offer superior resistance to corrosion. The design includes robust mounting points and a structure that ensures stability under various conditions. Additionally, the bracket may feature unique characteristics such as a protective coating or specialized alloys that further improve its resistance to environmental factors.

Benefits

Utilizing the Corrosion Resistor Bracket in commercial trucks offers several advantages. It contributes to the improved longevity of attached components by providing a barrier against corrosion. This, in turn, can lead to reduced maintenance costs and enhanced overall performance of the truck. The bracket’s durable construction ensures that it can withstand the rigors of heavy-duty use, making it a valuable addition to any truck’s component lineup.

Installation

Proper installation of the Corrosion Resistor Bracket is crucial for ensuring its effectiveness. The process involves securing the bracket to the designated mounting points on the truck, ensuring a snug and stable fit. It is important to follow the manufacturer’s guidelines to avoid common mistakes such as over-tightening or improper alignment, which can compromise the bracket’s functionality.

Troubleshooting

Occasionally, issues may arise with the Corrosion Resistor Bracket, such as signs of corrosion, loose fittings, or structural damage. Identifying these problems early is important for maintaining the bracket’s effectiveness. Troubleshooting steps may include inspecting the bracket for visible damage, tightening any loose fittings, and applying a protective coating if corrosion is detected. In cases of significant damage, replacement may be necessary to ensure continued protection of the attached components.

Maintenance

Regular maintenance of the Corrosion Resistor Bracket is recommended to ensure its continued performance. This includes routine inspections for signs of wear or damage, cleaning the bracket to remove any buildup that could accelerate corrosion, and applying a protective coating as needed. Knowing when to consider replacement or repair is also part of effective maintenance, helping to maintain the bracket’s effectiveness over time.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, with a history of producing high-quality components. The company’s product range includes a variety of parts designed for durability and performance in heavy-duty applications. Cummins’ commitment to quality and innovation is evident in its manufacturing processes and the reputation of its products among truck operators and maintenance professionals.

Cummins Corrosion Resistor Bracket 3047367 Compatibility

The Cummins Corrosion Resistor Bracket part number 3047367 is designed to be compatible with a range of Cummins engines, ensuring robust protection against corrosion in various engine environments. This bracket is specifically engineered to fit seamlessly with the following engine models:

-

K19 Engines

- The K19 engines benefit from the corrosion resistor bracket by providing a reliable mounting point that helps to shield critical components from corrosive elements. This bracket is essential in maintaining the longevity and performance of the engine by preventing rust and other forms of corrosion.

-

QSK19 CM2350

- For the QSK19 CM2350 engine, the corrosion resistor bracket plays a crucial role in protecting the engine’s internal components from environmental factors that can lead to corrosion. Its precise fit ensures that the bracket remains secure and effective over the engine’s operational life.

-

K114, QSK19 CM500, QSK19 CM850 MCRS

- The K114, QSK19 CM500, and QSK19 CM850 MCRS engines also integrate the corrosion resistor bracket to enhance durability and reliability. This bracket is designed to withstand the rigors of continuous operation and harsh conditions, providing a stable and corrosion-resistant mounting solution.

By using the Cummins Corrosion Resistor Bracket 3047367, these engines can operate more efficiently and with reduced maintenance needs, ensuring that they remain in optimal condition for extended periods.

Role of Part 3047367 Corrosion Resistor Bracket in Engine Systems

The Part 3047367 Corrosion Resistor Bracket is integral to the secure and efficient operation of various engine components. This bracket is designed to mount resistors in environments where corrosion could otherwise compromise performance and longevity.

Integration with Engine Components

-

Resistor Mounting: The primary function of the Corrosion Resistor Bracket is to provide a stable mounting solution for resistors. By securely holding resistors in place, it ensures that these components remain in the correct position and orientation, which is essential for the accurate functioning of the electrical circuits within the engine system.

-

Corrosion Resistance: In engine environments, components are often exposed to moisture, chemicals, and varying temperatures, all of which can lead to corrosion. The Corrosion Resistor Bracket is engineered to withstand these conditions, protecting the resistors and other connected components from corrosive damage. This ensures that the electrical properties of the resistors remain consistent over time, maintaining the reliability of the engine’s electrical systems.

-

Thermal Management: Resistors can generate heat during operation. The bracket’s design allows for adequate heat dissipation, preventing overheating that could lead to component failure. Proper thermal management is vital for the sustained performance of resistors and the overall engine system.

-

Vibration Dampening: Engines are subject to significant vibrations. The Corrosion Resistor Bracket is designed to absorb and dampen these vibrations, ensuring that the resistors remain securely mounted and function correctly without being dislodged or damaged.

-

Electrical Isolation: The bracket provides necessary electrical isolation between the resistor and other metal components, preventing short circuits and ensuring that the electrical current flows as intended through the resistor.

-

Space Optimization: In compact engine designs, space is at a premium. The Corrosion Resistor Bracket is designed to efficiently use available space, allowing for the optimal placement of resistors without interfering with other components.

By fulfilling these roles, the Part 3047367 Corrosion Resistor Bracket contributes to the reliable and efficient operation of engine systems, ensuring that resistors perform their intended functions under various operating conditions.

Conclusion

The Corrosion Resistor Bracket, part number 3047367, manufactured by Cummins, is a critical component in the protection and longevity of commercial truck components. Its design and features ensure that it can withstand harsh environmental conditions, providing a stable and corrosion-resistant mounting solution for various engine components. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part, ensuring the reliable and efficient operation of truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.