This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

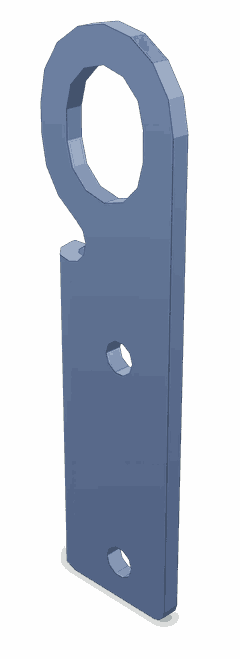

The 4982770 Lifting Bracket, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, is known for producing high-quality heavy-duty truck components. This Cummins part is integral to the maintenance and operational efficiency of commercial trucks. It facilitates the safe and effective lifting and securing of heavy components during maintenance or repair work, playing a significant role in the overall maintenance strategy for heavy-duty trucks.

Basic Concepts of Lifting Brackets

Lifting brackets are mechanical devices used in the automotive industry to support and lift heavy components safely. In the context of heavy-duty trucks, these brackets are essential for tasks that involve the removal or installation of large parts, such as engines or transmissions. The mechanical principles behind lifting brackets involve the distribution of weight and the application of leverage to lift heavy loads without causing strain or damage. Their role in ensuring safe and efficient truck maintenance cannot be overstated, as they help prevent accidents and equipment damage during servicing 1.

Purpose of the 4982770 Lifting Bracket

The 4982770 Lifting Bracket is specifically designed to aid in the lifting and securing of heavy components within commercial trucks. It is used during maintenance or repair operations to provide a stable and secure point for lifting equipment to attach. This bracket ensures that the lifting process is conducted safely and efficiently, reducing the risk of injury to personnel and damage to the truck’s components. Its application is vital for maintaining the operational integrity and safety of commercial trucks.

Key Features

The 4982770 Lifting Bracket boasts several key features that enhance its functionality and durability in heavy-duty applications. Its design incorporates robust materials and precise engineering to withstand the stresses of lifting heavy loads. Unique attributes, such as its ergonomic design for easy attachment and detachment, contribute to its effectiveness. These features ensure that the bracket can endure the rigors of commercial truck maintenance while providing a reliable solution for lifting operations.

Benefits of Using the 4982770 Lifting Bracket

Utilizing the 4982770 Lifting Bracket offers several advantages in truck maintenance practices. It improves safety during lifting operations by providing a secure attachment point for lifting equipment. Its durable construction ensures longevity, reducing the need for frequent replacements. Additionally, the bracket’s design facilitates ease of use, allowing for quick and efficient attachment and detachment. These benefits contribute to more efficient and safer maintenance procedures for commercial trucks 2.

Installation and Usage Guidelines

Proper installation and usage of the 4982770 Lifting Bracket are crucial for its effectiveness and safety. Installation should follow manufacturer guidelines to ensure secure attachment to the truck’s structure. Usage involves attaching lifting equipment to the bracket and ensuring that all connections are secure before lifting. Best practices include regular inspections of the bracket for wear or damage and adhering to weight limits specified by the manufacturer. These steps ensure the bracket’s optimal performance and safety during use.

Troubleshooting and Maintenance

Common issues with lifting brackets may include wear and tear, misalignment, or damage from heavy use. Troubleshooting steps involve inspecting the bracket for any signs of damage, ensuring it is correctly aligned, and replacing any worn or damaged components. Regular maintenance, such as cleaning and checking for structural integrity, is vital to ensure the longevity and optimal performance of the 4982770 Lifting Bracket. Regular inspections help identify potential issues before they lead to safety concerns or equipment failure 3.

Safety Considerations

When using the 4982770 Lifting Bracket, adhering to safety protocols is paramount. This includes following manufacturer guidelines for installation, usage, and weight limits. Safety standards should be observed to prevent accidents and ensure operational safety. This involves using the bracket within its specified parameters, ensuring all personnel are trained in its use, and conducting regular safety checks. Adhering to these safety considerations helps maintain a safe working environment during truck maintenance operations.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the production of heavy-duty truck components. The company is committed to quality, innovation, and customer satisfaction, ensuring that its products meet the highest standards of performance and reliability. Cummins’ extensive range of components, including the 4982770 Lifting Bracket, reflects its dedication to enhancing the efficiency and safety of commercial truck operations.

Cummins Engine Part 4982770: Lifting Bracket Compatibility

The Cummins part 4982770, a Lifting Bracket, is designed to be compatible with a range of Cummins engines. This part is essential for safely lifting and securing the engine during maintenance and installation processes. Below is a detailed overview of the engines with which this lifting bracket is compatible:

Compatible Engines

- D4.0 CM2620 D103B

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B

- ISB4.5 CM2350 B104

- ISF3.8 CM2220 AN

- ISF3.8 CM2350 F109

- QSF3.8 CM2880 F112

Grouping of Compatible Engines

Group 1: F3.8 Series

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

- F3.8 F102

- ISF3.8 CM2220 AN

- ISF3.8 CM2350 F109

- QSF3.8 CM2880 F112

The F3.8 series engines share a common architecture, making the lifting bracket compatible across these models. This commonality allows for streamlined maintenance and repair processes.

Group 2: F4.5 Series

- F4.5 CM2620 F139B

The F4.5 series engine, while slightly different in specifications, is also compatible with the lifting bracket. This compatibility ensures that the same lifting bracket can be used across different engine sizes within the same series.

Group 3: ISB4.5 Series

- ISB4.5 CM2350 B104

The ISB4.5 series engine is another model that fits the lifting bracket. This compatibility is crucial for efficient engine handling and maintenance.

Standalone Models

- D4.0 CM2620 D103B

The D4.0 CM2620 D103B engine, while unique in its specifications, is also compatible with the lifting bracket. This ensures that even less common engines can be maintained with the same lifting hardware.

By ensuring compatibility across these various engine models, the Cummins part 4982770 Lifting Bracket provides a versatile solution for engine maintenance and installation.

Role of Part 4982770 Lifting Bracket in Engine Systems

Part 4982770, the Lifting Bracket, is integral to the lifting arrangement in engine systems. It serves as a pivotal attachment point for hoists and rigging equipment, facilitating the safe and efficient lifting of heavy engine components during maintenance, repair, or installation processes.

When integrated into the lifting arrangement, the Lifting Bracket ensures that the load is distributed evenly, minimizing the risk of damage to both the engine components and the lifting equipment. It interfaces with various engine components such as the engine block, cylinder heads, and turbochargers, providing a secure connection point that allows for precise maneuvering.

In practical application, the Lifting Bracket is often used in conjunction with slings and spreader bars to maintain balance and stability during lifts. Its design allows for versatile attachment configurations, accommodating different lifting scenarios and ensuring that the engine components are handled with the utmost care.

The Lifting Bracket also plays a role in enhancing workplace safety by providing a reliable point of attachment, reducing the likelihood of accidents during lifting operations. Its integration into the lifting arrangement is a testament to its importance in maintaining the integrity and safety of engine maintenance procedures 4.

Conclusion

The 4982770 Lifting Bracket by Cummins is a critical component in the maintenance and repair of commercial trucks and engines. Its robust design, compatibility with various Cummins engines, and the safety it provides during lifting operations make it an indispensable tool for professionals in the automotive industry. Proper installation, regular maintenance, and adherence to safety protocols ensure the optimal performance and longevity of this part, contributing to the overall efficiency and safety of truck and engine maintenance procedures.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.