This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

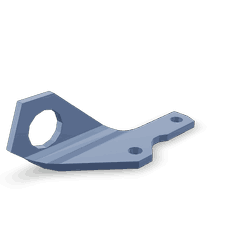

The Cummins 4982525 Lifting Bracket is a specialized component designed for commercial trucks, facilitating secure handling and lifting of heavy engine components during maintenance and repair. Its robust design and functionality are tailored to meet the demanding requirements of commercial truck operations, ensuring both efficiency and safety 1.

Purpose and Functionality

This Cummins part is utilized to secure and lift substantial components during maintenance or repair activities. It provides a stable and reliable point of attachment for lifting equipment, allowing for the safe manipulation of heavy parts. The bracket is integral in scenarios where precise and secure lifting is required to avoid damage to the vehicle or injury to personnel 2.

Key Features

The design of the 4982525 incorporates robust material characteristics that enhance its performance and durability. Crafted from high-strength materials, it is engineered to withstand the rigors of commercial truck environments. Unique attributes of this bracket include its precise engineering for optimal strength-to-weight ratio and its design that ensures compatibility with standard lifting equipment used in the industry 3.

Benefits

The 4982525 Lifting Bracket offers several advantages. It contributes to improved safety during lifting operations by providing a secure attachment point, reducing the risk of accidents. Its durable construction ensures long-term reliability, minimizing the need for frequent replacements. Additionally, the bracket is designed for ease of use, allowing for quick and efficient attachment and detachment during maintenance tasks.

Installation Process

Proper installation of the Lifting Bracket involves several steps. First, identify the correct location on the truck where the bracket will be attached. Use the appropriate tools to secure the bracket in place, ensuring it is firmly fastened. It may be necessary to use additional components, such as bolts or spacers, to complete the installation. Always refer to the manufacturer’s guidelines for specific instructions and torque specifications.

Maintenance and Care

To ensure the longevity and reliable performance of the 4982525, regular maintenance and care are recommended. Inspect the bracket for any signs of wear or damage before each use. Clean the bracket and its attachment points to remove any debris or corrosion that could affect its performance. Lubricate moving parts as necessary to ensure smooth operation.

Troubleshooting Common Issues

Common problems with the 4982525 may include corrosion, wear, or loose connections. To address these issues, first, inspect the bracket for any visible damage or corrosion. Tighten any loose connections and replace any worn or damaged components. Regular maintenance, as outlined above, can help prevent many of these issues from arising.

Safety Considerations

When using the 4982525, it is important to observe safety practices and precautions. Ensure that the bracket is properly installed and secured before use. Use appropriate personal protective equipment (PPE) when handling heavy components. Follow operational guidelines provided by the manufacturer to ensure safe and effective use of the bracket.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, continually advancing its product offerings to meet the evolving needs of its customers.

Role of Part 4982525 Lifting Bracket in Engine Systems

The 4982525 is an essential component in the arrangement and handling of engine systems, particularly when dealing with the long block. This bracket facilitates the secure lifting and positioning of the long block during installation, maintenance, or removal processes.

When integrating the Lifting Bracket with the engine system, it is attached to specific mounting points on the long block. These mounting points are strategically located to ensure balanced lifting, minimizing the risk of damage to the engine components. The bracket’s design allows for even distribution of weight, which is vital during the lifting process to prevent undue stress on any single part of the engine.

In practical application, the Lifting Bracket is used in conjunction with lifting equipment such as cranes or hoists. Once the bracket is securely fastened to the long block, the lifting equipment can be hooked to the bracket, enabling the engine to be lifted smoothly and safely. This setup is particularly beneficial in workshops where precise alignment and secure handling of heavy engine components are required.

Additionally, the Lifting Bracket plays a role in the overall arrangement of the engine within the vehicle’s chassis. By providing a stable and reliable means to lift the long block, it allows mechanics and engineers to position the engine accurately within the engine bay. This is important for ensuring proper clearances, alignment with other components, and overall fitment within the vehicle.

Conclusion

The Cummins 4982525 Lifting Bracket is a critical component in the maintenance and repair of commercial trucks, offering durability, safety, and efficiency in lifting operations. Its robust design and precise engineering make it an indispensable tool for mechanics and engineers working with Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.