This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

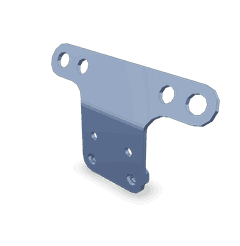

The 4975430 Wiring Retainer Bracket, manufactured by Cummins, is a component designed to enhance the electrical system’s organization and security in commercial trucks. Cummins, a well-established name in the commercial truck industry, ensures that this bracket meets the rigorous demands of heavy-duty applications, contributing to the efficient and reliable operation of trucks 1.

Basic Concepts of Wiring Retainer Brackets

A Wiring Retainer Bracket is a device used in vehicle electrical systems to organize and secure wiring. Its primary function is to maintain the integrity of the electrical connections by preventing wires from moving excessively, which could lead to wear, damage, or disconnection. This organization is vital for the consistent performance of the truck’s electrical system, ensuring that all components receive the necessary power without interruption 2.

Purpose of the 4975430 Wiring Retainer Bracket

This Cummins part is specifically designed to play a role in the electrical system of a truck by organizing and securing wiring. This bracket helps in maintaining the position of wires, reducing the risk of electrical faults that could arise from loose or damaged wires. By securing the wiring, it also contributes to the overall safety and reliability of the truck’s electrical system 3.

Key Features

The 4975430 Wiring Retainer Bracket boasts several key features that enhance its functionality. It is constructed from durable materials to withstand the harsh conditions of commercial truck operations. Its design includes specific elements that allow for easy installation and adjustment, ensuring that it can accommodate various wiring configurations. Additionally, the bracket’s unique characteristics, such as its robust construction and precise engineering, contribute to its effectiveness in securing and organizing wiring 4.

Benefits

The advantages provided by the 4975430 Wiring Retainer Bracket include improved wire management, which leads to a more organized and secure electrical system. This organization reduces the risk of electrical faults, enhancing the truck’s reliability. Furthermore, the bracket’s durable construction ensures longevity, providing a cost-effective solution for wire management in commercial trucks 1.

Installation Process

Installing the 4975430 Wiring Retainer Bracket involves several steps to ensure proper placement and functionality. First, identify the location where the bracket will be installed, ensuring it is in a position that allows for effective wire management. Next, use the appropriate tools to secure the bracket in place, following the manufacturer’s guidelines for tightness and alignment. Finally, route the wiring through the bracket, adjusting as necessary to ensure all wires are securely held in place 4.

Troubleshooting Common Issues

Common problems associated with Wiring Retainer Brackets may include loose connections or damage to the bracket itself. To address these issues, first, inspect the bracket and wiring for any signs of wear or damage. If the bracket is loose, tighten the mounting screws to secure it in place. For damaged brackets, replacement may be necessary to ensure the continued reliability of the electrical system 2.

Maintenance Tips

Regular maintenance of the 4975430 Wiring Retainer Bracket is crucial for its longevity and optimal performance. This includes periodic inspection of the bracket and wiring for signs of wear, damage, or loose connections. Cleaning the bracket to remove any dirt or debris that could affect its functionality is also recommended. Following these maintenance routines will help ensure the bracket continues to provide effective wire management 3.

Compatibility and Applications

The 4975430 Wiring Retainer Bracket is designed for use in a variety of trucks, demonstrating its versatility and widespread application in the industry. Its compatibility with different truck models highlights its importance in maintaining the electrical system’s integrity across various commercial truck operations 4.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. With a history of innovation and excellence, Cummins has established a reputation for producing components that meet the demanding requirements of heavy-duty applications. The 4975430 Wiring Retainer Bracket is a testament to Cummins’ dedication to enhancing the performance and reliability of commercial trucks 1.

Cummins Wiring Retainer Bracket 4975430 Compatibility

The Cummins Wiring Retainer Bracket, part number 4975430, is designed to fit seamlessly with several engine models. This bracket is essential for maintaining the integrity of the engine’s wiring system by securing and organizing the wiring harness. Below is a detailed look at the compatibility of this part with specific engine models:

QST30 CM2350 T101 and QST30 CM552

The Wiring Retainer Bracket 4975430 is specifically engineered to fit the QST30 CM2350 T101 and QST30 CM552 engines. These engines are known for their robust performance and reliability, often used in various industrial and commercial applications. The bracket ensures that the wiring harness remains properly positioned and protected, preventing any potential damage that could arise from movement or vibration 4.

Installation and Functionality

When installing the Wiring Retainer Bracket 4975430 on these engines, it is crucial to follow the manufacturer’s guidelines to ensure proper fitment and functionality. The bracket typically attaches to specific mounting points on the engine, securing the wiring harness in place. This not only aids in maintaining the structural integrity of the wiring system but also helps in improving the overall efficiency and safety of the engine operation 4.

Importance of Proper Fitment

Ensuring that the Wiring Retainer Bracket is correctly installed is vital for the longevity and performance of the engine. A well-fitted bracket prevents the wiring harness from becoming loose or damaged, which could lead to electrical issues and potential engine malfunctions. Regular checks and maintenance of the bracket can help in identifying any wear or damage early, allowing for timely repairs and avoiding costly downtime 3.

By understanding the compatibility and installation process of the Wiring Retainer Bracket 4975430 with the QST30 CM2350 T101 and QST30 CM552 engines, technicians and operators can ensure that their engines run smoothly and efficiently 4.

Role of Part 4975430 Wiring Retainer Bracket in Engine Systems

The 4975430 Wiring Retainer Bracket is an essential component in maintaining the integrity and organization of the wiring systems within various engine setups. This bracket is strategically positioned to secure and retain wiring harnesses and electronic control module (ECM) wiring, ensuring they remain in place and protected from potential damage.

In systems equipped with aftercoolers, the Wiring Retainer Bracket interfaces with the aftercooler (left) brackets. This integration helps in stabilizing the wiring that runs alongside the aftercooler, preventing it from being dislodged or damaged during engine operation. The bracket’s design allows for efficient routing of wires, reducing the risk of chafing against moving parts or heat sources 4.

When it comes to the harness and ECM wiring, the bracket plays a significant role in maintaining a tidy and secure environment. By clamping down on these wires, it prevents them from vibrating loose, which could lead to intermittent connections or complete failure of the electronic control systems. This is particularly important in high-vibration environments typical of engine compartments 2.

The bracket also contributes to the overall mounting strategy of the engine control module. By providing a stable platform for the ECM wiring, it ensures that the module receives consistent power and data signals. This reliability is vital for the engine control system to function correctly, as any disruption in the wiring could lead to erroneous readings or commands 3.

In summary, the 4975430 Wiring Retainer Bracket is a key component in the engine’s electrical system, offering stability, protection, and organization to the wiring harnesses and ECM wiring. Its proper installation and maintenance are essential for the reliable operation of the engine control systems 4.

Conclusion

The 4975430 Wiring Retainer Bracket by Cummins is a critical component for maintaining the integrity and organization of the electrical systems in commercial trucks. Its durable construction, ease of installation, and compatibility with various engine models make it a valuable asset for ensuring the reliable operation of truck electrical systems. Regular maintenance and proper installation are essential for maximizing the benefits of this Cummins part.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩ ↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ ↩ ↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ ↩ ↩ ↩ -

Cummins Inc. (n.d.). QSK78 CM2350 K154C, Service Manual (5676944).

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.