This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

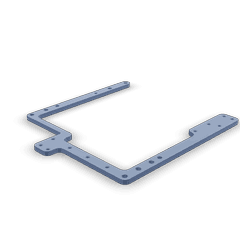

The Cummins 4967295 Heat Shield Bracket is a component designed for use in heavy-duty truck systems. Its primary role is to support and position the heat shield, which protects surrounding components from excessive heat generated by the engine and exhaust system. This bracket ensures that the heat shield remains in the correct position, thereby contributing to the efficient and safe operation of the truck’s engine system 3.

Purpose and Function

The Heat Shield Bracket plays a role in the engine system by securing the heat shield in place. The heat shield, in turn, protects nearby components from the high temperatures produced by the engine and exhaust. This protection helps maintain the integrity and functionality of these components, which can be adversely affected by prolonged exposure to heat. By reducing the risk of heat-related damage, the bracket contributes to the overall efficiency and safety of the truck’s engine system 4.

Key Features

The Cummins 4967295 Heat Shield Bracket is designed with specific characteristics to enhance its performance and durability. It is typically made from high-strength materials that can withstand the rigors of heavy-duty truck environments. The bracket’s design ensures a secure fit for the heat shield, minimizing the risk of displacement or failure. Additionally, it may feature corrosion-resistant coatings or treatments to prolong its service life in harsh conditions 2.

Benefits

The use of the Heat Shield Bracket offers several advantages. By effectively supporting the heat shield, it helps improve engine longevity by reducing the wear and tear on nearby components caused by heat. This can lead to fewer repairs and maintenance interventions. Additionally, the bracket contributes to enhanced overall performance of the truck by ensuring that the engine system operates within optimal temperature ranges 3.

Installation and Compatibility

Proper installation of the Heat Shield Bracket is vital for its effective function. Installation procedures typically involve securing the bracket to the truck’s chassis or engine compartment in the designated location. It is important to follow manufacturer guidelines to ensure correct placement and attachment. Compatibility information, including specific truck models and engine types, should be consulted to ensure the bracket is suitable for the intended application 1.

Maintenance and Troubleshooting

Regular maintenance of the Heat Shield Bracket is recommended to ensure its optimal functioning. This may include inspecting the bracket and heat shield for signs of wear, corrosion, or damage, and performing any necessary repairs or replacements. Common issues that may arise include bracket displacement, heat shield deterioration, or fastener corrosion. Troubleshooting steps may involve re-securing the bracket, replacing the heat shield, or addressing corrosion with appropriate treatments 2.

Safety Considerations

When handling and installing the Heat Shield Bracket, it is important to follow safety protocols to mitigate potential hazards. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against sharp edges or hot surfaces. Additionally, ensuring that the engine and exhaust system are cool before beginning work can help prevent burns or other injuries 4.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has built a reputation for excellence in the manufacturing of automotive parts. The company’s dedication to research and development ensures that its products, including the 4967295 Heat Shield Bracket, meet the demanding requirements of heavy-duty truck applications 3.

Engine Compatibility

The Heat Shield Bracket 4967295 is designed to fit seamlessly within the engine architecture of several Cummins models. This part is engineered to provide thermal protection and structural support, ensuring the longevity and efficiency of the engine.

QSK60 and CM850 Engines

The Heat Shield Bracket 4967295 is specifically tailored for the QSK60 and CM850 engines. These engines are known for their robust performance and reliability in demanding applications. The bracket’s design allows it to interface with the engine’s heat management systems, effectively shielding sensitive components from excessive heat. This is particularly important in maintaining optimal engine operation and preventing thermal damage 3.

MCRS Engines

The MCRS engines also benefit from the Heat Shield Bracket 4967295. This part is engineered to fit precisely within the MCRS engine’s layout, providing essential thermal protection and structural integrity. The bracket’s placement is critical in ensuring that the engine’s components remain within safe operating temperatures, thereby enhancing the engine’s overall performance and lifespan 3.

Grouping Considerations

While the Heat Shield Bracket 4967295 is designed to fit the QSK60, CM850, and MCRS engines individually, its compatibility within these engines is grouped based on the shared thermal management needs and structural requirements. This ensures that the bracket provides consistent performance across different engine models, maintaining the high standards of quality and reliability associated with Cummins products 3.

Role of Part 4967295 Heat Shield Bracket in Engine Systems

When integrating the 4967295 Heat Shield Bracket into engine systems, particularly those equipped with a turbocharger, its function becomes apparent. The Heat Shield Bracket is designed to mitigate the intense heat generated by the turbocharger, which operates at extremely high temperatures due to the compression of air and the subsequent combustion process.

The bracket securely holds the heat shield in place, ensuring it effectively covers and insulates nearby components from the turbocharger’s heat. This includes protecting the engine bay’s wiring harnesses, fuel lines, and other sensitive parts that could be damaged by prolonged exposure to high temperatures.

Additionally, the Heat Shield Bracket plays a role in maintaining the overall thermal management of the engine system. By reducing heat transfer to adjacent components, it helps in preserving their structural integrity and operational efficiency. This is particularly important in high-performance engines where components are already operating at their thermal limits 4.

In turbocharged engines, where the turbocharger itself can reach temperatures exceeding 1,000 degrees Fahrenheit, the Heat Shield Bracket ensures that the heat does not adversely affect the surrounding engine components. This not only enhances the durability of the engine but also contributes to its reliable performance over time 4.

The effective placement and secure fitting of the Heat Shield Bracket are essential for optimal engine operation, ensuring that the benefits of turbocharging are realized without compromising the integrity of the engine’s other critical components 4.

Conclusion

The Cummins 4967295 Heat Shield Bracket is a vital component in heavy-duty truck engine systems, providing essential thermal protection and structural support. Its design and features ensure the efficient and safe operation of the engine, contributing to the longevity and performance of the truck. Proper installation, maintenance, and adherence to safety protocols are crucial for maximizing the benefits of this Cummins part.

-

R2.8 CM2220 R101B, Bulletin Number 5467557, Operation and Maintenance Manual

↩ -

A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Allan Bonnick and Derek Newbold, Elsevier Ltd, 2011

↩ ↩ -

Vocational Vehicles and Applications, Michael Hilgers and Wilfried Achenbach, Springer Vieweg, 2021

↩ ↩ ↩ ↩ ↩ ↩ -

Light and Heavy Vehicle Technology, Fourth Edition, MJ Nunney, Butterworth-Heinemann, 2007

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.