This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

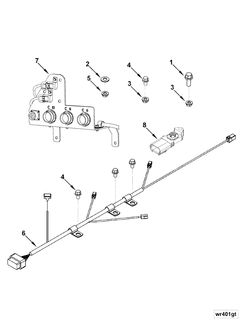

The Cummins 4967001 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses within heavy-duty trucks. Its role is significant in maintaining the integrity and safety of the truck’s electrical system, ensuring that wires are properly managed and protected from potential damage 1.

Purpose and Function

The primary role of the Wiring Retainer Bracket is to secure and organize the wiring harnesses within the truck. By holding the wires in place, it helps prevent them from coming into contact with moving parts or sharp edges, which could lead to wear, fraying, or even electrical faults. This organization contributes to the overall integrity of the electrical system, enhancing safety and reliability during operation 2.

Key Features

The Cummins 4967001 Wiring Retainer Bracket is crafted from durable materials, ensuring it can withstand the rigors of heavy-duty truck environments. Its design includes features that allow for easy attachment and adjustment, facilitating secure and organized wire management. The bracket’s robust construction and thoughtful design contribute to its performance and longevity 3.

Benefits

Utilizing the Cummins 4967001 Wiring Retainer Bracket offers several advantages. It improves wire management by keeping wires neatly organized and secured, which reduces the risk of electrical faults. This organization also enhances safety during operation by minimizing the chances of wire damage or interference with other components. Additionally, proper wire management can lead to easier troubleshooting and maintenance, contributing to the overall efficiency of the truck’s electrical system 4.

Installation and Usage

Proper installation of the Wiring Retainer Bracket involves securing it in a location that allows for optimal wire management without obstructing other components. It should be fastened securely to ensure it remains in place under the dynamic conditions of truck operation. Careful consideration should be given to the routing of wires through the bracket to avoid tension or sharp bends that could lead to damage 1.

Maintenance and Troubleshooting

Regular inspection of the Wiring Retainer Bracket is recommended to ensure it remains securely fastened and that the wires are in good condition. Common issues may include loose brackets or damaged wires, which can be addressed by re-securing the bracket or repairing/replacing the affected wires. Attention to these details can help maintain the effectiveness of the electrical system 2.

Safety Considerations

When installing or maintaining the Wiring Retainer Bracket, it is important to follow safety guidelines to avoid electrical hazards. This includes ensuring the truck’s electrical system is de-energized before beginning work, using appropriate personal protective equipment, and verifying that all connections are secure to prevent electrical shorts or fires 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, including diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins plays a significant role in the development and production of automotive components, including the 4967001 Wiring Retainer Bracket, designed to meet the demanding requirements of heavy-duty truck operations 4.

Cummins Wiring Retainer Bracket 4967001 in Engine Applications

The Cummins Wiring Retainer Bracket 4967001 is a component used in various Cummins engine models. This part is designed to secure and organize the wiring harness within the engine compartment, ensuring that electrical connections remain stable and protected from potential damage.

QSK19 Engines

In the QSK19 series, the Wiring Retainer Bracket 4967001 plays a role in maintaining the integrity of the engine’s electrical system. This engine series is known for its robust performance and reliability, often used in heavy-duty applications such as marine and industrial settings. The bracket helps in managing the complex wiring layout, ensuring that all connections are secure and easily accessible for maintenance.

CM850 Engines

The CM850 engines benefit from the use of the Wiring Retainer Bracket 4967001. These engines are typically employed in commercial and industrial applications, where durability and efficiency are paramount. The bracket aids in the efficient routing and securing of wiring, which is important for the engine’s operational efficiency and longevity.

MCRS Engines

For the MCRS engines, the Wiring Retainer Bracket 4967001 is part of the engine’s electrical management system. These engines are often utilized in military and defense applications, where reliability and performance under extreme conditions are important. The bracket ensures that the wiring is properly managed, reducing the risk of electrical faults and enhancing the overall safety and reliability of the engine.

Grouping Considerations

When considering the application of the Wiring Retainer Bracket 4967001 across different engine series, it is important to note that while the specific engine models may vary, the fundamental role of the bracket remains consistent. It provides a reliable means of securing and organizing the wiring harness, which is important for the proper functioning of the engine’s electrical system.

Role of Part 4967001 Wiring Retainer Bracket in Engine Systems

The 4967001 Wiring Retainer Bracket is a component in organizing and securing the wiring systems within engine compartments. It is specifically designed to work in conjunction with the Electronic Control Module (ECM) Wiring Harness and the overall Harness system.

Integration with ECM Wiring Harness

The ECM Wiring Harness is a network of wires that connect the ECM to various sensors, actuators, and other electronic components within the engine system. The 4967001 Wiring Retainer Bracket plays a role in this setup by providing a secure mounting point for the harness. This ensures that the wires are neatly organized and protected from potential damage caused by engine vibrations or heat.

Securing the Harness

Beyond the ECM Wiring Harness, the 4967001 Wiring Retainer Bracket is also integral in securing the broader Harness system. This includes all the wiring that runs throughout the engine compartment, connecting different components and systems. By clamping down on these wires, the bracket prevents them from becoming tangled or frayed, which could lead to electrical issues or even failures.

Enhancing System Reliability

The proper installation of the 4967001 Wiring Retainer Bracket contributes to the overall reliability of the engine’s electrical system. It ensures that all connections remain intact and that the wiring is less likely to be affected by the harsh environment within the engine compartment. This, in turn, helps maintain the efficiency and performance of the engine.

Facilitating Maintenance and Repairs

In addition to its role during normal operation, the 4967001 Wiring Retainer Bracket also aids in maintenance and repair processes. By keeping the wiring organized and accessible, it simplifies the process of diagnosing and addressing electrical issues. Mechanics can more easily trace wires, identify problems, and make necessary repairs or adjustments.

Conclusion

The Cummins 4967001 Wiring Retainer Bracket is a vital component in the maintenance and operation of heavy-duty truck electrical systems. Its design and functionality contribute to the safety, reliability, and efficiency of the truck’s electrical system, making it an essential part for any heavy-duty application.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ ↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ ↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.