This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

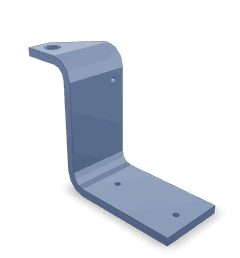

The Magnetic Switch Mounting Bracket, identified by part number 4944244, is a component manufactured by Cummins, a well-established leader in the automotive and heavy-duty truck industry. This bracket is integral to the operational efficiency of commercial trucks, facilitating the secure and effective mounting of magnetic switches. Its role in ensuring the proper function of various truck systems underscores its significance in maintaining vehicle performance and reliability 1.

Purpose and Function

The Magnetic Switch Mounting Bracket serves a pivotal role in the operation of a truck by providing a stable and secure platform for the magnetic switch. This bracket ensures that the magnetic switch is correctly positioned and aligned, which is crucial for its interaction with other components and systems within the truck. The magnetic switch, when properly mounted, can accurately detect the presence of metal objects, which is often used in applications such as proximity sensing for automated systems or safety mechanisms. The bracket’s design allows for precise placement, ensuring that the switch operates within specified parameters and interacts effectively with the truck’s electronic systems 2.

Key Features

The Magnetic Switch Mounting Bracket is designed with several key features that enhance its performance and durability. Constructed from high-strength materials, the bracket is built to withstand the rigors of commercial truck operations. Its design includes provisions for easy attachment and adjustment, allowing for versatile installation in various truck models. The bracket is also engineered to provide a stable and vibration-resistant mount, which is critical for the accurate functioning of the magnetic switch. Additionally, the bracket’s design incorporates corrosion-resistant coatings, ensuring longevity and reliability in diverse operating environments 3.

Benefits

The Magnetic Switch Mounting Bracket offers several advantages that contribute to the overall efficiency and reliability of truck operations. By providing a secure and stable mount for the magnetic switch, the bracket helps ensure consistent and accurate performance of the switch. This, in turn, enhances the reliability of the systems that depend on the switch’s input, such as automated braking systems or proximity sensors. The bracket’s easy installation and maintenance features also contribute to reduced downtime and lower maintenance costs, making it a valuable component for fleet operators.

Installation Process

Installing the Magnetic Switch Mounting Bracket involves several steps to ensure proper setup and function. Begin by identifying the correct mounting location on the truck, ensuring it aligns with the intended application of the magnetic switch. Secure the bracket to the truck using the provided fasteners, ensuring a tight and stable fit. Next, mount the magnetic switch onto the bracket, making any necessary adjustments to ensure it is aligned correctly and operates within its specified parameters. Finally, test the switch to confirm it is functioning as intended, making any further adjustments if necessary.

Troubleshooting and Maintenance

Common issues with the Magnetic Switch Mounting Bracket may include misalignment of the magnetic switch, corrosion, or physical damage to the bracket. To address these issues, begin by inspecting the bracket and switch for any signs of wear or damage. Ensure the bracket is securely fastened and the switch is properly aligned. If corrosion is present, clean the affected areas and apply a corrosion-resistant coating. Regular maintenance, including periodic inspections and cleaning, will help prevent issues and ensure the continued reliable operation of the bracket and switch.

Safety Considerations

When working with the Magnetic Switch Mounting Bracket, it is important to follow several safety guidelines to ensure proper handling and usage. Always wear appropriate personal protective equipment, such as gloves and safety glasses, when installing or maintaining the bracket. Ensure the truck is parked on a level surface and the engine is turned off before beginning any work. Follow all manufacturer instructions for installation and maintenance to avoid damage to the bracket or switch. Additionally, be aware of the magnetic properties of the switch and avoid placing metallic objects near the switch during operation to prevent interference.

Cummins Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, with a rich history of innovation and quality. Established in 1919, Cummins has built a reputation for producing reliable and high-performance components that meet the demanding requirements of commercial truck operations. The company’s commitment to quality is evident in its rigorous testing and quality control processes, ensuring that each component, including the Magnetic Switch Mounting Bracket, meets the highest standards of performance and durability. Cummins continues to lead the industry with its focus on innovation, providing solutions that enhance the efficiency and reliability of commercial trucks.

Compatibility with Cummins Engines

This Cummins part is designed to fit seamlessly with specific Cummins engine models. This part is essential for the proper installation and operation of the magnetic switch, which plays a vital role in the engine’s ignition system.

QSB6.7 M CM2250

The QSB6.7 M CM2250 engine benefits from the precise fit of the 4944244 bracket. This bracket ensures that the magnetic switch is securely mounted, allowing for consistent and reliable engine performance. The bracket’s design is tailored to the unique specifications of the QSB6.7 M CM2250, ensuring optimal alignment and functionality.

QSC8.3 CM850 (CM2850)

Similarly, the QSC8.3 CM850 (CM2850) engine is engineered to work with the 4944244 Magnetic Switch Mounting Bracket. This bracket is integral to the engine’s ignition system, providing a stable mounting point for the magnetic switch. The bracket’s compatibility with the QSC8.3 CM850 (CM2850) ensures that the engine operates smoothly and efficiently, with the magnetic switch positioned correctly for optimal performance.

By ensuring that the magnetic switch is securely mounted, the 4944244 bracket helps maintain the integrity of the engine’s ignition system, contributing to the overall reliability and longevity of the engine.

Role in Engine Systems

The 4944244 Magnetic Switch Mounting Bracket is integral to the efficient operation of electric starting systems in engines. This component serves as a secure attachment point for the magnetic switch, ensuring it remains firmly in place during engine operation.

When integrated with the electric starting system, the mounting bracket allows for the precise alignment of the magnetic switch with other components, such as the starter solenoid and the battery terminals. This alignment is essential for the reliable transmission of electrical signals that initiate the starting sequence.

In addition, the mounting bracket facilitates the connection of accessories that rely on the electric starting system. These accessories may include ignition systems, fuel pumps, and other engine control units that require a stable and consistent power supply.

The secure attachment provided by the mounting bracket ensures that the magnetic switch can withstand the vibrations and stresses inherent in engine operation, maintaining a stable electrical connection. This stability is vital for the consistent performance of the starting system, contributing to the overall reliability and efficiency of the engine.

Conclusion

The 4944244 Magnetic Switch Mounting Bracket is a critical component in the operation of commercial trucks and Cummins engines. Its role in securely mounting the magnetic switch ensures the reliable function of various truck systems, contributing to the overall performance and reliability of the vehicle. The bracket’s design, featuring high-strength materials, easy installation, and corrosion-resistant coatings, enhances its durability and effectiveness. Regular maintenance and adherence to safety guidelines are essential for the continued reliable operation of this part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.