This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

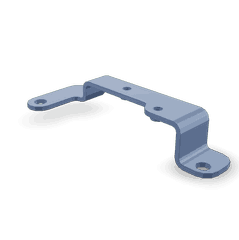

The Cummins 4943061 Wiring Retainer Bracket is a component designed for use in commercial trucks. It serves to secure and organize the wiring harnesses within the vehicle’s electrical system. This bracket plays a role in maintaining the structural integrity and operational efficiency of the truck’s electrical components 1.

Purpose and Function

The primary purpose of the Wiring Retainer Bracket is to hold wiring harnesses in place, ensuring they remain organized and protected within the truck’s chassis. By securing the harnesses, the bracket helps prevent chafing, abrasion, and potential damage to the wires, which could lead to electrical faults. It operates as part of the truck’s electrical system by providing a stable mounting point for the harnesses, thereby contributing to the overall reliability and safety of the vehicle’s electrical operations 2.

Key Features

The Cummins 4943061 Wiring Retainer Bracket is characterized by its robust design and the materials used in its construction. It is typically made from durable plastics or metals, chosen for their strength and resistance to the harsh conditions found under the hood of commercial trucks. The bracket’s design includes features such as mounting points and clips that allow for secure attachment of the wiring harnesses. These attributes enhance its performance and durability, ensuring it can withstand the vibrations and environmental factors encountered in truck operations 3.

Benefits

The use of the Wiring Retainer Bracket offers several benefits. It improves the organization of wiring harnesses, making them less susceptible to damage from moving parts or environmental factors. This organization reduces the risk of electrical issues that could arise from damaged or disconnected wires. Additionally, by securing the harnesses, the bracket contributes to the enhanced safety and reliability of the truck’s electrical system, potentially reducing downtime and maintenance costs.

Installation and Usage

Proper installation of the Wiring Retainer Bracket is crucial for its effective function. Installation guidelines recommend identifying the correct location for the bracket within the truck’s chassis, ensuring it is securely fastened to prevent movement. Tools required may include wrenches or screwdrivers, depending on the bracket’s design. Precautions during installation include ensuring the bracket does not interfere with other components and that all wiring is properly secured and protected.

Maintenance and Troubleshooting

To ensure the optimal performance of the Wiring Retainer Bracket, regular maintenance is advised. This includes inspecting the bracket for signs of wear, corrosion, or damage and cleaning it as necessary to remove any debris or contaminants. Addressing common issues such as corrosion or physical damage to the bracket promptly can help maintain the integrity of the truck’s electrical system and prevent potential failures.

Manufacturer Information

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to quality and innovation in producing automotive components. With a history of developing reliable and efficient parts for commercial vehicles, Cummins has built a reputation for excellence. The company’s dedication to advancing technology and improving product performance underscores its position as a leader in the industry.

Compatibility with Cummins Engines

This Cummins part, the Wiring Retainer Bracket 4943061, is designed to be compatible with a range of Cummins engines. It plays a role in securing and organizing the wiring harness within the engine compartment, ensuring that electrical connections remain stable and protected.

ISB (Chrysler)

The ISB engine, developed by Chrysler, is a robust and reliable power unit that has been widely adopted in various applications. The Wiring Retainer Bracket 4943061 fits seamlessly with the ISB engine, providing a secure mounting point for the wiring harness. This helps in maintaining the integrity of the electrical system and prevents any potential damage due to movement or vibration.

ISB CM850

The ISB CM850 engine is another variant within the Cummins ISB family, known for its efficiency and power. The Wiring Retainer Bracket 4943061 is engineered to integrate perfectly with the ISB CM850, ensuring that the wiring harness is properly anchored. This bracket is essential for maintaining the structural integrity of the engine’s electrical system, particularly in demanding environments where vibrations and movement are common.

Grouping of Engines

The compatibility of the Wiring Retainer Bracket 4943061 with the ISB and ISB CM850 engines highlights the importance of using OEM-approved parts for maintenance and repairs. Cummins has designed this bracket to fit multiple models within the ISB series, demonstrating a commitment to providing reliable and versatile solutions for their engine lineup. This ensures that users can maintain their engines with confidence, knowing that the parts are specifically engineered for their applications.

Role in Engine Systems

The 4943061 Wiring Retainer Bracket is a component in maintaining the integrity and organization of the engine control wiring harness within various engine systems. This bracket securely holds the wiring harness in place, ensuring that the wires remain protected from potential damage caused by engine vibrations, heat, and moving parts.

When installed, the Wiring Retainer Bracket keeps the engine control wiring neatly organized and away from high-temperature areas and sharp edges. This not only enhances the durability of the wiring but also ensures consistent and reliable electrical connections. Proper retention of the wiring harness is vital for the efficient operation of the engine control system, as it prevents wires from becoming frayed, disconnected, or short-circuited.

Additionally, the bracket aids in simplifying the diagnostic and maintenance processes. By keeping the wiring harness in an orderly manner, technicians can more easily access and inspect the wires, reducing the time required for troubleshooting and repairs. This organization also minimizes the risk of accidental damage during routine maintenance checks.

Conclusion

In summary, the 4943061 Wiring Retainer Bracket plays a role in safeguarding the engine control wiring harness, contributing to the overall reliability and performance of the engine system. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of organization, protection, and maintenance make it a valuable component in the electrical systems of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.