This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4927617 Wiring Retainer Bracket is a component designed to secure and organize wiring within commercial trucks. Its purpose is to maintain the integrity of the electrical system by keeping wires in place and protecting them from potential damage. This Cummins part plays a role in ensuring the reliable operation of the truck’s electrical components 1.

Basic Concepts of Wiring Retainer Brackets

A Wiring Retainer Bracket is a device used in a vehicle’s electrical system to hold and organize wires. It contributes to the overall performance and safety of the truck by preventing wires from coming into contact with moving parts or sharp edges, which could lead to damage or short circuits. Proper wire management is vital for the consistent and safe operation of the vehicle’s electrical systems 2.

Purpose of the 4927617 Wiring Retainer Bracket

The 4927617 is specifically designed to secure and route wires within the electrical system of a truck. It helps in maintaining wire integrity by preventing chafing, abrasion, and other forms of damage that could occur during vehicle operation. This bracket ensures that wires remain in their designated paths, reducing the risk of electrical faults.

Key Features

The 4927617 features a robust construction, typically made from durable materials to withstand the harsh conditions found in commercial truck environments. Its design includes elements that allow for easy wire routing and secure attachment points. Unique attributes may include corrosion-resistant coatings and adjustable mounting options to accommodate various wiring configurations.

Benefits

The 4927617 offers several benefits, including improved wire management that enhances the organization and protection of the electrical system. Its durable construction contributes to the longevity of the wiring, potentially reducing maintenance needs and associated costs. Enhanced durability also means fewer interruptions in service due to electrical issues.

Installation Process

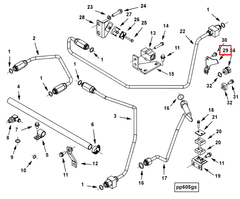

Installing the 4927617 involves several steps to ensure optimal performance. Begin by identifying the correct location for the bracket within the truck’s electrical system. Use the appropriate tools to secure the bracket in place, ensuring it is firmly attached to the vehicle’s structure. Route the wires through the bracket, making sure they are snugly held without being overly tight, which could cause damage. Finally, inspect the installation to confirm that all wires are properly secured and the bracket is stable.

Troubleshooting Common Issues

Common problems with Wiring Retainer Brackets may include wire chafing or bracket misalignment. To address wire chafing, inspect the area for any signs of wear or damage and adjust the bracket or wiring as necessary to prevent further abrasion. For bracket misalignment, ensure that the bracket is correctly installed and securely fastened. If necessary, reposition the bracket to achieve the proper alignment and secure it again.

Maintenance Tips

Regular maintenance of the 4927617 involves inspecting it for signs of wear, corrosion, or damage. Cleaning the bracket and surrounding areas can prevent the buildup of dirt and debris that could affect its performance. Schedule inspections as part of routine vehicle maintenance to ensure the bracket remains in good condition and continues to effectively protect the wiring.

Compatibility and Applications

The 4927617 is designed for use in specific types of trucks and electrical systems. It is important to verify compatibility with the truck model and electrical system to ensure proper fit and function. This bracket is commonly used in applications where reliable wire management and protection are critical for the safe and efficient operation of the vehicle.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration, and power generation equipment. The company has a reputation for quality and reliability, which is reflected in its components like the 4927617. Cummins’ commitment to innovation and customer satisfaction underscores the trust placed in its products by professionals in the industry 3.

Cummins Engine Compatibility with Wiring Retainer Bracket 4927617

The Wiring Retainer Bracket 4927617, manufactured by Cummins, is a component in the electrical systems of several Cummins engine models. This part is designed to secure and organize wiring harnesses, ensuring that electrical connections remain stable and protected from potential damage.

QSK60 Series

The QSK60 series engines, known for their robust performance and reliability, integrate the Wiring Retainer Bracket 4927617 to maintain the integrity of their electrical systems. This bracket is essential in managing the complex wiring configurations found in these high-output engines, ensuring that all electrical components function optimally.

CM850 Series

In the CM850 series, the Wiring Retainer Bracket 4927617 plays a pivotal role in the engine’s electrical architecture. These engines, often used in marine and industrial applications, benefit from the bracket’s ability to keep wiring organized and secure, which is crucial for maintaining consistent performance and reliability in demanding environments.

MCRS Series

The MCRS series engines, designed for heavy-duty applications, also utilize the Wiring Retainer Bracket 4927617. This part is integral to the MCRS engines’ electrical systems, providing the necessary support and organization for wiring harnesses. Its use in these engines ensures that electrical connections remain intact, even under the most strenuous conditions.

By incorporating the Wiring Retainer Bracket 4927617, Cummins ensures that these engines maintain their high standards of performance and reliability, providing a seamless and efficient electrical system.

Role of Part 4927617 Wiring Retainer Bracket in Engine Systems

The wiring retainer bracket, specifically part 4927617, is a component in maintaining the integrity and organization of the wiring systems within various engine components. It ensures that wires are securely held in place, preventing them from coming into contact with moving parts such as the camshaft and valve mechanisms.

When installed, the wiring retainer bracket supports the wiring that connects to the injector and the engine control module (ECM). This is particularly important in high-performance engines where the wiring must withstand vibrations and heat. The bracket helps to maintain a tidy and efficient wiring layout, which is vital for the reliable operation of performance parts.

Additionally, the bracket plays a role in protecting the wiring from potential damage caused by the movement of the cylinder head and other engine parts. By securing the wires, it ensures that they do not interfere with the operation of these components, thereby contributing to the overall performance and reliability of the engine system.

Conclusion

In summary, the wiring retainer bracket is a key element in the engine’s electrical system, ensuring that all connections remain secure and organized, which is essential for the engine’s performance and longevity.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Cummins Inc. Company Overview. Available at: Cummins Official Website (Accessed: March 2024).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.