This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

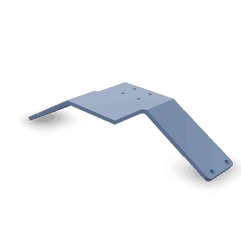

The Cummins 4924859 Heat Shield Bracket is a component designed to enhance the operation of commercial trucks. Its primary role is to support and secure the heat shield within the engine compartment, ensuring that it functions effectively to manage engine heat and protect surrounding components.

Purpose and Function

The Heat Shield Bracket serves a function in a truck’s engine compartment by supporting the heat shield. This bracket helps in positioning the heat shield correctly, which in turn aids in directing and dissipating heat away from sensitive engine components. By managing heat effectively, the bracket contributes to the overall performance and safety of the vehicle, ensuring that engine components operate within optimal temperature ranges and reducing the risk of heat-related damage 1.

Key Features

This Cummins part is engineered with several key features that enhance its functionality. It is constructed from durable materials that can withstand high temperatures and the rigors of commercial truck operation. The design of the bracket ensures a secure fit for the heat shield, with precise mounting points that allow for easy installation and adjustment. Additionally, the bracket may incorporate features such as heat-resistant coatings or specialized fasteners to further improve its performance and longevity 2.

Benefits

The installation of the Heat Shield Bracket offers several benefits. It plays a role in heat management by ensuring the heat shield is properly positioned to reflect and dissipate heat away from critical engine components. This not only helps in maintaining optimal engine temperature but also protects nearby components from heat damage. Furthermore, by contributing to efficient heat management, the bracket can indirectly support engine efficiency, potentially leading to improved fuel economy and reduced emissions 3.

Installation and Compatibility

Proper installation of the Heat Shield Bracket is important for its effective function. It should be securely fastened according to the manufacturer’s guidelines to ensure it holds the heat shield in the correct position. Compatibility with various truck models and engine types is a consideration, and it is important to verify that the bracket is suitable for the specific application to ensure optimal performance and safety 4.

Maintenance and Troubleshooting

Regular maintenance of the Heat Shield Bracket is recommended to ensure its continued effectiveness. This may include checking for secure fastening, inspecting for signs of wear or damage, and ensuring that the heat shield remains in good condition. Common issues that may arise include loosening of the bracket or damage to the heat shield, which can be addressed through re-tightening fasteners or replacing damaged components as necessary.

Safety Considerations

When handling and installing the Heat Shield Bracket, it is important to observe safety measures. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines for installation. Operational safety measures, such as regular inspections and maintenance, are also important to ensure the bracket continues to function as intended throughout the vehicle’s service life.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation in automotive components. With a rich history of providing reliable and high-performance parts, Cummins continues to play a significant role in advancing the efficiency, safety, and durability of commercial vehicles. The company’s dedication to excellence is evident in its wide range of products, including the 4924859 Heat Shield Bracket, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Heat Shield Bracket 4924859 Compatibility

The Cummins Heat Shield Bracket 4924859 is designed to fit seamlessly within a range of Cummins engines, ensuring optimal thermal management and operational efficiency. This part is crucial for maintaining the integrity of the engine’s cooling system by providing a secure mounting point for the heat shield.

QSK60 and CM850 Engines

The Heat Shield Bracket 4924859 is specifically engineered to integrate with the QSK60 and CM850 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as marine and industrial sectors. The bracket’s design ensures that the heat shield is properly aligned and secured, preventing any potential movement that could lead to overheating or damage.

MCRS Engines

Similarly, the MCRS engines benefit from the use of the Heat Shield Bracket 4924859. This bracket is essential for maintaining the structural integrity of the heat shield, which is vital for protecting sensitive engine components from excessive heat. The bracket’s precision fit ensures that the heat shield remains in place under all operating conditions, contributing to the longevity and efficiency of the engine.

Grouping for Efficiency

By grouping the QSK60 and CM850 engines together, it is evident that the Heat Shield Bracket 4924859 is designed to cater to engines that share similar operational demands and environments. This commonality allows for a standardized approach to thermal management, ensuring that the bracket performs consistently across different engine models. The MCRS engines, while distinct, also benefit from this bracket’s design, highlighting its versatility and effectiveness in various applications.

Role of Part 4924859 Heat Shield Bracket in Engine Systems

The Part 4924859 Heat Shield Bracket is a component in managing thermal conditions within engine systems. It is strategically positioned to safeguard adjacent components from excessive heat generated during engine operation.

Integration with Plumbing Components

When integrated with the plumbing components of an engine system, the Heat Shield Bracket ensures that the hoses and pipes remain within their optimal operating temperatures. This is particularly important for systems where coolant or other fluids are circulated under high temperatures. The bracket helps in maintaining the integrity of the plumbing by preventing thermal expansion and potential leaks that could arise from prolonged exposure to heat.

Function in Aftercooler Water Systems

In aftercooler water systems, the Heat Shield Bracket plays a significant role in protecting the aftercooler and associated water lines. The aftercooler is a component that cools the compressed air from the turbocharger before it enters the engine’s intake system. By shielding the aftercooler and its water lines from direct heat, the bracket helps in maintaining efficient cooling performance. This, in turn, ensures that the air entering the engine is at the desired temperature, contributing to better engine efficiency and performance.

The Heat Shield Bracket also aids in reducing the overall thermal load on the aftercooler system. By mitigating heat transfer, it helps in preserving the effectiveness of the cooling process, which is vital for the longevity and reliability of the engine system.

Conclusion

The Cummins 4924859 Heat Shield Bracket is a vital component in the thermal management of commercial truck engines. Its design and features contribute to the efficient operation of the engine by protecting sensitive components from excessive heat, ensuring optimal engine performance, and enhancing safety. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the Heat Shield Bracket, making it a reliable choice for commercial truck applications.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Singh, D. K. Dictionary of Mechanical Engineering. Springer Nature, 2024.

↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.