4917562

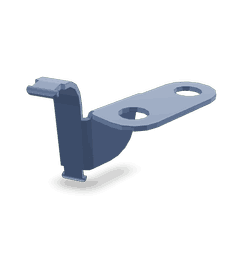

Wiring Retainer Bracket

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4917562 Wiring Retainer Bracket is a component manufactured by Cummins, a well-established name in the commercial truck industry. This bracket is designed to play a significant role in the electrical systems of commercial trucks, contributing to the overall efficiency and reliability of truck operations.

Purpose of the Wiring Retainer Bracket

The Wiring Retainer Bracket serves to secure and organize wiring harnesses within a truck’s electrical system. By holding the wiring in place, it helps prevent damage from vibrations and movement, ensuring that electrical connections remain reliable. This function is vital for maintaining the integrity of the truck’s electrical system, which is essential for the operation of various components and systems within the vehicle 1.

Key Features

This Cummins part is constructed with durability and performance in mind. It is made from high-quality materials that can withstand the harsh conditions often encountered in commercial truck environments. The design includes mounting options that allow for flexible installation in various truck configurations. Additionally, the bracket may feature unique characteristics such as corrosion-resistant coatings or ergonomic designs that enhance its functionality and longevity 2.

Benefits

Incorporating the 4917562 into a truck’s electrical system offers several advantages. It improves wire management by keeping wiring harnesses organized and protected, which can reduce the risk of electrical faults. This, in turn, enhances the overall safety and reliability of the truck’s electrical system, contributing to more efficient and trouble-free operations 3.

Installation and Maintenance

Proper installation of the Wiring Retainer Bracket is key to ensuring its effectiveness. Recommended tools and procedures should be followed to secure the bracket in place and connect it to the wiring harnesses. Routine maintenance, including periodic inspections for signs of wear or damage, is also important to ensure continued optimal performance. This may involve checking for loose connections, signs of corrosion, or physical damage to the bracket or wiring 4.

Troubleshooting Common Issues

Common problems associated with wiring retainer brackets can include loose connections, corrosion, or physical damage. Troubleshooting these issues involves a systematic approach to diagnose and resolve problems effectively. This may include tightening connections, cleaning or replacing corroded parts, or repairing or replacing damaged components to restore the bracket’s functionality.

Compatibility and Applications

The 4917562 is compatible with a range of truck models and engine types manufactured by Cummins. Its applications extend to various commercial truck configurations and operating environments, making it a versatile component for enhancing the electrical systems of commercial vehicles.

Safety Considerations

When working with electrical components and wiring retainer brackets, it is important to observe safety precautions and best practices. This includes following manufacturer guidelines and industry standards to ensure safe and reliable operation. Proper handling, installation, and maintenance of electrical components are crucial for the safety of personnel and the reliability of the vehicle.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality, innovation, and customer satisfaction. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, designed to meet the demanding requirements of commercial truck operations. Cummins’ reputation for excellence is built on a foundation of rigorous testing, advanced engineering, and a dedication to providing reliable and high-performance components for the automotive industry.

Cummins Wiring Retainer Bracket 4917562 Compatibility

The Cummins Wiring Retainer Bracket, part number 4917562, is designed to secure and organize wiring within the engine compartment. This bracket is engineered to fit seamlessly with several Cummins engine models, ensuring that electrical connections remain stable and protected.

QSK60 and CM850 Engines

The QSK60 and CM850 engines are part of Cummins’ heavy-duty diesel engine lineup, known for their robust performance and reliability in demanding applications. The Wiring Retainer Bracket 4917562 is specifically designed to integrate with these engines, providing a secure mounting point for wiring harnesses. This ensures that the electrical systems remain organized, reducing the risk of damage from vibrations and environmental factors.

MCRS Engines

The MCRS (Modular Component Reconfigurable System) engines are another series where the Wiring Retainer Bracket 4917562 proves indispensable. These engines are designed for flexibility and modularity, allowing for various configurations to meet specific operational needs. The bracket’s design ensures that wiring is neatly managed, facilitating easier maintenance and troubleshooting. This is particularly important in environments where space is limited, and the organization of electrical components can significantly impact overall efficiency.

Grouping of Engines

The QSK60 and CM850 engines, while distinct in their applications, share a common requirement for reliable wiring management. The Wiring Retainer Bracket 4917562 is engineered to meet these needs, providing a consistent solution across both engine types. Similarly, the MCRS engines benefit from the bracket’s design, which supports the modular nature of these engines by keeping wiring organized and secure.

Role of Part 4917562 Wiring Retainer Bracket in Engine Systems

The 4917562 Wiring Retainer Bracket is a component in organizing and securing wiring within engine systems. Its primary function is to maintain the integrity and safety of the electrical connections by preventing wires from coming into contact with moving parts or hot surfaces.

Integration with the Engine Control Module (ECM)

When integrating with the Engine Control Module (ECM), the 4917562 Wiring Retainer Bracket ensures that the sensitive wiring connected to the ECM is neatly organized and protected. This is particularly important as the ECM relies on consistent and reliable data from various sensors to manage engine performance. The bracket helps in reducing the risk of wire damage, which could lead to intermittent connections or complete failure of the ECM system.

Application in Engine Systems

In engine systems, the 4917562 Wiring Retainer Bracket plays a role in maintaining the structural integrity of the wiring harness. It secures wires that run from the ECM to various components such as sensors, actuators, and other control units. By keeping these wires in place, the bracket helps in preventing chafing against sharp edges or vibrations that could degrade the wire insulation over time.

Enhancing System Reliability

The use of the 4917562 Wiring Retainer Bracket enhances the overall reliability of the engine system. It ensures that all electrical connections remain secure and undisturbed, which is vital for the consistent operation of the engine. This is especially important in high-vibration environments where unsecured wiring can lead to significant issues.

Supporting Diagnostic and Maintenance Efforts

From a maintenance perspective, the 4917562 Wiring Retainer Bracket simplifies diagnostic efforts. By keeping wires organized and easily accessible, technicians can more quickly identify and address any issues that may arise. This not only saves time but also reduces the likelihood of misdiagnosis due to tangled or obscured wiring.

Conclusion

The 4917562 Wiring Retainer Bracket is a critical component in the electrical systems of commercial trucks, offering benefits such as improved wire management, enhanced safety, and increased reliability. Proper installation, maintenance, and troubleshooting are essential to ensure its effectiveness and the overall performance of the vehicle’s electrical system.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Bonnick, Allan, and Derek Newbold. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.