This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

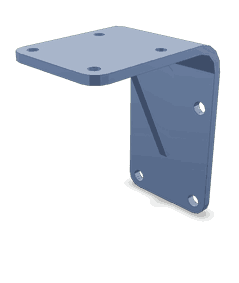

The Corrosion Resistor Bracket 4910300 is a component designed by Cummins, a leading manufacturer in the heavy-duty truck industry. This bracket is engineered to enhance the durability and functionality of heavy-duty trucks by providing resistance to corrosion. Cummins is renowned for its commitment to quality and innovation, making this part a reliable choice for truck operators and maintenance professionals.

Purpose and Function

The Corrosion Resistor Bracket 4910300 plays a role in protecting critical components of heavy-duty trucks from the adverse effects of corrosion. By securing and supporting various parts, it contributes to the overall functionality and longevity of the vehicle. Its design ensures that even in harsh environments, the bracket maintains its integrity, thereby supporting the truck’s performance and reliability 1.

Key Features

The Corrosion Resistor Bracket 4910300 is constructed using high-quality materials that are resistant to corrosion, such as treated steel or specialized alloys. Its design incorporates features that enhance its durability and effectiveness, including precise engineering to fit securely within the truck’s structure. Additionally, the bracket may feature coatings or treatments that further protect against environmental factors, ensuring long-term performance 2.

Benefits

One of the primary advantages of the Corrosion Resistor Bracket 4910300 is its improved resistance to environmental factors, which can significantly extend the lifespan of the components it supports. This enhanced durability can lead to potential cost savings over time, as the need for frequent replacements or repairs is reduced. Furthermore, the bracket’s reliable performance contributes to the overall efficiency and safety of the truck 3.

Installation

Proper installation of the Corrosion Resistor Bracket 4910300 is vital to ensure optimal performance. It is recommended to follow the manufacturer’s guidelines closely, which may include specific torque settings for fasteners and alignment instructions. Ensuring that the bracket is correctly positioned and secured will help maintain its effectiveness and contribute to the truck’s overall durability.

Maintenance and Troubleshooting

To ensure the longevity and performance of the Corrosion Resistor Bracket 4910300, regular maintenance is advised. This may include inspecting the bracket for signs of wear or corrosion, ensuring that all fasteners are tight, and cleaning the area around the bracket to prevent the buildup of debris. Common issues that may arise include loosening of fasteners or minor corrosion, which can often be addressed through routine checks and adjustments.

Environmental Considerations

The use of the Corrosion Resistor Bracket 4910300 can contribute to the overall environmental performance of the truck by reducing the frequency of maintenance and replacement needs. This not only minimizes waste but also reduces the environmental impact associated with manufacturing and disposing of replacement parts. Additionally, the longevity provided by the bracket can lead to more efficient truck operations, potentially lowering fuel consumption and emissions over time 4.

Compatibility and Applications

The Corrosion Resistor Bracket 4910300 is designed for use in a variety of heavy-duty truck models and engine types. It is commonly applied in trucks that operate in challenging environments, where corrosion resistance is particularly beneficial. Specific application notes may include compatibility with certain engine models or truck makes, ensuring that the bracket is suited to the intended use.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the heavy-duty truck industry. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of modern transportation and power generation needs.

Cummins Corrosion Resistor Bracket 4910300 Compatibility

The Cummins Corrosion Resistor Bracket, part number 4910300, is designed to enhance the durability and longevity of specific engine models by providing resistance against corrosion. This part is engineered to fit seamlessly within the architecture of various Cummins engines, ensuring optimal performance and protection.

QSK19 and CM2350 Engines

The QSK19 and CM2350 engines, both known for their robust design and high performance, benefit significantly from the installation of the 4910300 bracket. This bracket is specifically tailored to fit into the structural framework of these engines, providing a reliable barrier against corrosive elements that can degrade engine components over time. Its precise engineering ensures that it integrates smoothly with the existing parts, maintaining the integrity of the engine’s design and function.

K105 Engine

Similarly, the K105 engine, which is part of Cummins’ lineup of reliable and efficient power solutions, is also compatible with the 4910300 Corrosion Resistor Bracket. This bracket is designed to fit the unique specifications of the K105, ensuring that it provides the necessary protection against corrosion without compromising the engine’s performance. Its integration into the K105’s design is seamless, contributing to the overall durability and efficiency of the engine.

By ensuring that the 4910300 bracket is compatible with these specific engine models, Cummins maintains a high standard of quality and reliability, providing engine owners with a part that enhances the lifespan and performance of their engines.

Role of Part 4910300 Corrosion Resistor Bracket in Engine Systems

The 4910300 Corrosion Resistor Bracket is a component in the assembly and maintenance of various engine systems. It is specifically designed to enhance the durability and efficiency of the engine by providing a robust mounting solution for the resistor.

In the context of engine systems, the resistor plays a role in regulating the electrical current, ensuring that the engine operates within safe parameters. The Corrosion Resistor Bracket, therefore, serves as a protective and supportive structure for the resistor, shielding it from environmental factors that could lead to corrosion.

This bracket is typically installed in areas where the resistor is exposed to moisture, chemicals, or high temperatures, which are common in engine compartments. By securing the resistor firmly in place, the bracket prevents it from shifting or becoming dislodged, which could otherwise lead to electrical malfunctions or engine performance issues.

Furthermore, the bracket’s corrosion-resistant properties ensure that it maintains its structural integrity over time, even in harsh operating conditions. This longevity is vital for the consistent performance of the resistor and, by extension, the engine system as a whole.

In summary, the 4910300 Corrosion Resistor Bracket is a key component in maintaining the reliability and efficiency of engine systems by providing a secure and corrosion-resistant mounting solution for the resistor.

Conclusion

The Corrosion Resistor Bracket 4910300 is a vital component for enhancing the durability and functionality of heavy-duty trucks and engines. Its corrosion-resistant properties, precise engineering, and compatibility with various engine models make it a reliable choice for truck operators and maintenance professionals. Proper installation, regular maintenance, and understanding its role in engine systems are essential for maximizing its benefits and ensuring the longevity and efficiency of the vehicle.

-

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Martyr, A. J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.