This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

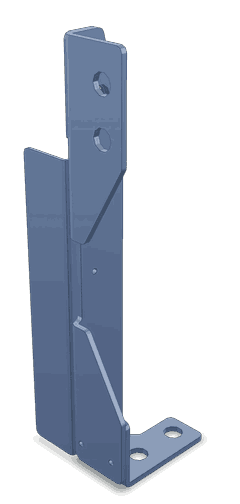

The Cummins 4385440 Heat Shield Bracket is a vital component in heavy-duty trucks, designed to enhance operational efficiency and safety. It protects adjacent components from the intense heat generated by the engine and exhaust system, contributing to the longevity and reliability of the truck’s systems 1.

Purpose and Function

The Heat Shield Bracket insulates and protects nearby components from high engine and exhaust temperatures. This protection is essential for maintaining the integrity and performance of these components. By reducing thermal stress, the bracket ensures parts operate within their designed parameters, contributing to the truck’s overall efficiency and safety 2.

Key Features

Engineered for durability and heat resistance, the Cummins 4385440 Heat Shield Bracket is constructed from high-quality materials to withstand extreme operating conditions. Its design allows for seamless integration with other truck components, ensuring a secure and effective fit. The bracket’s robust construction and precise engineering make it a reliable component in heavy-duty trucking 3.

Benefits

Installing this Cummins part offers several advantages. It enhances the longevity of adjacent components by shielding them from excessive heat, which can lead to premature wear and failure. Improved safety is another benefit, as the bracket helps prevent heat-related issues that could pose risks to the vehicle and its occupants. Additionally, by reducing thermal stress on nearby parts, the bracket may contribute to potential fuel efficiency gains, as components operate more efficiently under optimal conditions.

Installation and Compatibility

Proper installation of the Heat Shield Bracket is crucial for its effective performance. Detailed guidelines should be followed to ensure it is securely and correctly fitted. The bracket is compatible with various Cummins engine models and has been designed to fit a range of truck makes and models, ensuring versatility and widespread applicability.

Maintenance and Troubleshooting

Regular inspection and maintenance of the Heat Shield Bracket are recommended to ensure its continued effectiveness. Common issues may include damage from road debris or wear over time. Troubleshooting steps should involve checking for signs of wear, ensuring secure attachment, and replacing the bracket if any damage is detected. Proper maintenance helps prevent potential issues and ensures the bracket continues to provide the intended protection.

Safety Considerations

The proper installation and maintenance of the Heat Shield Bracket are important for the safety of the vehicle and its occupants. A malfunctioning or damaged heat shield can lead to increased thermal stress on nearby components, potentially causing failures that could affect the truck’s operation. Ensuring the bracket is in good condition and correctly installed helps mitigate these risks.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality components and innovative solutions in the automotive and heavy-duty truck industries. With a rich history of engineering excellence, Cummins plays a significant role in developing and producing components like the 4385440 Heat Shield Bracket, which are designed to enhance the performance, efficiency, and safety of heavy-duty trucks.

Compatibility with Cummins Engines

The Cummins Heat Shield Bracket, part number 4385440, is designed to fit seamlessly with several high-performance Cummins engines, ensuring optimal thermal management and operational efficiency. This bracket is crucial for maintaining the integrity of the engine’s heat shield system, which helps in protecting sensitive components from excessive heat.

QSK95 Engine

The QSK95 engine series, known for its robust design and high power output, benefits significantly from the Heat Shield Bracket 4385440. This bracket is engineered to fit precisely with the QSK95, ensuring that the heat shield remains securely in place, thereby enhancing the engine’s overall performance and longevity.

CM2350 Engine

The CM2350 engine, a part of Cummins’ medium-duty engine lineup, is another beneficiary of the Heat Shield Bracket 4385440. This bracket’s design aligns perfectly with the CM2350’s specifications, providing a reliable solution for heat management. Its integration with the CM2350 ensures that the engine operates within safe temperature limits, contributing to its durability and efficiency.

K113 Engine

The K113 engine, recognized for its versatility and adaptability across various applications, also integrates the Heat Shield Bracket 4385440 effectively. This bracket’s compatibility with the K113 ensures that the heat shield is optimally positioned, safeguarding the engine from thermal stress and enhancing its operational lifespan.

Grouping for Efficiency

The Heat Shield Bracket 4385440 is designed to be versatile across different engine models, making it a valuable component for maintenance and repair. Its compatibility with the QSK95, CM2350, and K113 engines highlights its importance in maintaining the thermal integrity of these engines, ensuring they perform reliably under various conditions.

Role of 4385440 Heat Shield Bracket in Engine Systems

The 4385440 Heat Shield Bracket is an integral component in the assembly and functionality of various engine systems. Its primary role is to securely mount the heat shield, which is essential for protecting adjacent components from the high temperatures generated by the engine.

Integration with Engine Components

-

Exhaust System: The Heat Shield Bracket is positioned to hold the heat shield in place over the exhaust manifold and pipes. This arrangement ensures that the intense heat from the exhaust is contained, preventing damage to nearby wiring, hoses, and other sensitive components.

-

Turbocharger: In turbocharged engines, the bracket supports the heat shield that covers the turbocharger and its associated piping. This shielding is vital for maintaining the structural integrity of the turbocharger and ensuring optimal performance by preventing heat-induced stress.

-

Fuel Lines: The bracket is also used to secure heat shields around fuel lines. This protection is important for preventing fuel line degradation due to excessive heat, which could lead to leaks or other dangerous conditions.

-

Wiring Harnesses: Electrical wiring harnesses routed near the engine can be susceptible to heat damage. The Heat Shield Bracket ensures that the heat shield effectively covers these harnesses, safeguarding them against heat-related failures.

-

Engine Bay Components: Various other engine bay components, such as sensors and control units, benefit from the protection offered by the heat shield secured by the bracket. This shielding helps in maintaining the operational efficiency and longevity of these components.

Functional Benefits

-

Thermal Management: By effectively holding the heat shield in place, the bracket plays a significant role in the thermal management of the engine bay. It helps in dissipating heat away from critical components, thus enhancing overall engine performance and reliability.

-

Safety: The bracket contributes to the safety of the engine system by reducing the risk of heat-related damages, which could lead to engine malfunctions or fires.

-

Durability: Protecting components from excessive heat prolongs their lifespan, reducing the need for frequent replacements and maintenance.

Conclusion

The Cummins 4385440 Heat Shield Bracket is a key component in ensuring the efficient and safe operation of engine systems by providing essential thermal protection to a variety of critical components. Its robust design, compatibility with various Cummins engines, and the functional benefits it offers make it an indispensable part of heavy-duty truck maintenance and operation.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.