This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

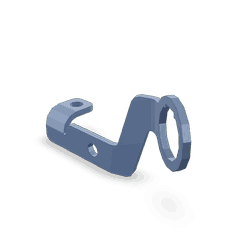

The 4383236 Wiring Retainer Bracket is a component designed to enhance the electrical system’s organization and security in heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical operations, ensuring that wiring harnesses are properly managed and secured.

Basic Concepts of Wiring Retainer Brackets

A Wiring Retainer Bracket serves as a structural element within a vehicle’s electrical system. Its primary function is to organize and secure wiring harnesses, preventing them from moving or becoming damaged during operation. This contributes to the overall reliability and safety of the truck’s electrical system by maintaining the integrity of the connections and reducing the risk of electrical faults 1.

Purpose of the 4383236 Wiring Retainer Bracket

This Cummins part is specifically designed to play a role in the electrical system of a truck by organizing and securing wiring harnesses. This ensures that the wires remain in place and are protected from potential damage caused by vibrations or movement, which can occur during the operation of a heavy-duty truck.

Key Features

The 4383236 features a robust construction, typically made from durable materials that can withstand the harsh conditions encountered in heavy-duty truck operations. Its design includes elements that allow for easy installation and secure fastening of wiring harnesses. Additionally, it may incorporate features that enhance its performance and durability, such as corrosion-resistant coatings or reinforced mounting points.

Benefits

The use of the 4383236 offers several benefits. It improves wire management within the truck, reducing the likelihood of wires becoming tangled or damaged. This, in turn, reduces the risk of electrical faults that could lead to system failures. Furthermore, its durable construction ensures that it can withstand the rigors of heavy-duty truck operations, providing long-lasting performance 2.

Installation Process

Installing this part requires following a series of steps to ensure it is securely and effectively placed. This process may involve using specific tools to fasten the bracket in place and ensuring that wiring harnesses are properly routed and secured within the bracket. Best practices include verifying that all connections are tight and that the bracket is firmly attached to prevent any movement that could lead to wire damage.

Troubleshooting Common Issues

Common issues with Wiring Retainer Brackets may include loose connections or damage to the bracket itself. Troubleshooting these problems involves inspecting the bracket and connections for signs of wear or damage, ensuring that all fasteners are tight, and replacing any damaged components as necessary to maintain the integrity of the electrical system.

Maintenance Tips

Regular maintenance of the 4383236 is important to ensure continued reliable performance. This includes periodic inspections to check for signs of wear or damage, ensuring that all connections remain secure, and cleaning the bracket to remove any debris that could affect its operation. Following these maintenance tips can help prevent issues and ensure the longevity of the component.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. The company’s history of innovation and excellence provides a solid foundation for the quality and performance of components like the 4383236, ensuring that it meets the demanding requirements of heavy-duty truck operations.

Compatibility

The Wiring Retainer Bracket part number 4383236, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This bracket is a crucial component in securing and organizing the engine’s wiring harness, ensuring that electrical connections remain stable and protected from potential damage.

QSK95 and CM2350 Engines

The QSK95 and CM2350 engines, both known for their robust performance and reliability, benefit from the precise fit and function of the 4383236. These engines are often utilized in heavy-duty applications, where maintaining the integrity of the wiring system is essential for operational efficiency and safety.

K113 Engine

Similarly, the K113 engine, which is part of Cummins’ lineup of industrial and marine engines, also integrates seamlessly with the 4383236. This compatibility ensures that the wiring harness is effectively managed, contributing to the overall reliability and longevity of the engine.

Compatibility Summary

- QSK95 Engine: The 4383236 is engineered to fit the QSK95 engine, providing a secure mounting point for the wiring harness.

- CM2350 Engine: This bracket is also suitable for the CM2350 engine, ensuring that the wiring is neatly organized and protected.

- K113 Engine: The K113 engine is another beneficiary of this bracket, which helps in maintaining the structural integrity of the wiring system.

Role of Part 4383236 Wiring Retainer Bracket in Engine Systems

The 4383236 is instrumental in maintaining the integrity and organization of the wiring system within engine assemblies. It is specifically designed to secure and manage the wiring harness and the Electronic Control Module (ECM) wiring, ensuring they remain in optimal condition and position.

Integration with Wiring Harness

The Wiring Retainer Bracket plays a significant role in supporting the wiring harness. By securely holding the harness in place, it prevents undue stress and potential damage to the wires. This is particularly important in dynamic environments where vibrations and movements are common. The bracket ensures that the harness remains taut and organized, reducing the risk of chafing against other components and maintaining efficient signal transmission.

Support for ECM Wiring

In addition to the harness, the Wiring Retainer Bracket is essential for the ECM wiring. The ECM is a vital component in modern engine systems, responsible for controlling various engine functions. The bracket ensures that the ECM wiring is neatly routed and protected. This is important for maintaining the reliability of the ECM signals, which are critical for the engine’s performance and diagnostics. By keeping the wiring organized and secure, the bracket helps in preventing issues such as short circuits or intermittent connections.

Overall System Benefits

The use of the Wiring Retainer Bracket in engine systems offers several benefits. It enhances the durability of the wiring by protecting it from physical damage and environmental factors. Additionally, it contributes to the overall neatness and professionalism of the engine compartment, making maintenance and troubleshooting more straightforward. The bracket also aids in reducing electromagnetic interference by keeping the wiring away from other electrical components, thus ensuring stable and reliable engine operation 3.

Conclusion

The 4383236 Wiring Retainer Bracket by Cummins is a vital component for maintaining the integrity and efficiency of heavy-duty truck electrical systems. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of wire management and protection make it an essential part for ensuring reliable engine operation and safety.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.