This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

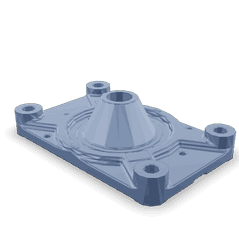

The Shock Absorber Bracket 4382822 is a component designed for use in the suspension systems of commercial trucks. Its purpose is to securely mount shock absorbers to the truck frame, thereby playing a role in the overall suspension system by ensuring the shock absorbers are correctly positioned and function as intended 1.

Basic Concepts of Shock Absorber Brackets

A Shock Absorber Bracket serves as a mounting point for shock absorbers within the suspension system. It facilitates the connection between the shock absorber and the truck frame, allowing the shock absorber to effectively manage the compression and rebound phases of the suspension. This interaction helps in absorbing and dissipating the energy generated by road irregularities, contributing to vehicle stability and ride comfort 2.

Purpose of the 4382822 Shock Absorber Bracket

The 4382822 Shock Absorber Bracket is integral to the operation of a truck’s suspension system. It contributes to maintaining vehicle stability by ensuring the shock absorber is correctly aligned and securely attached to the frame. This alignment is vital for the shock absorber to effectively perform its function, which in turn enhances ride comfort by reducing the impact of road irregularities on the vehicle and its occupants. Additionally, the proper functioning of the shock absorber, supported by the bracket, helps in the overall efficiency and longevity of the suspension system 3.

Key Features

The 4382822 Shock Absorber Bracket is characterized by its robust design and material composition, which typically includes high-strength steel to withstand the stresses and strains of commercial truck operations. It features precise mounting points that ensure accurate alignment of the shock absorber with the truck frame. Unique characteristics may include corrosion-resistant coatings or treatments that enhance its performance and durability in various operating environments 4.

Benefits

The use of the 4382822 Shock Absorber Bracket offers several benefits. It contributes to improved handling by ensuring the shock absorber is correctly positioned, which is crucial for the vehicle’s response to steering inputs and road conditions. Reduced wear on suspension components is another advantage, as the bracket helps maintain the optimal operation of the shock absorber, thereby extending the lifespan of both the bracket and the shock absorber. Enhanced safety is a direct result of the improved stability and handling, while the increased longevity of the shock absorbers can lead to cost savings over time.

Installation Process

Installing the 4382822 Shock Absorber Bracket requires careful attention to detail to ensure optimal performance. The process involves preparing the mounting area on the truck frame, aligning the bracket with the designated mounting points, and securing it in place using the appropriate fasteners. Tools required may include a torque wrench to ensure fasteners are tightened to the manufacturer’s specifications, and alignment tools to confirm the bracket is correctly positioned relative to the shock absorber and frame.

Troubleshooting Common Issues

Common issues with the 4382822 Shock Absorber Bracket may include mounting problems, such as misalignment or looseness, which can affect the performance of the shock absorber. Damage to the bracket, such as cracks or bends, may also occur due to impacts or corrosion. Troubleshooting steps involve inspecting the bracket for signs of damage or wear, ensuring it is correctly aligned and securely fastened, and replacing it if necessary to maintain the integrity of the suspension system.

Maintenance Tips

Regular maintenance of the 4382822 Shock Absorber Bracket is important for its longevity and effectiveness. This includes periodic inspection for signs of wear, corrosion, or damage, and cleaning the bracket and its mounting points to remove dirt and debris that could affect its performance. It is also advisable to check the tightness of the fasteners at regular intervals to ensure the bracket remains securely attached to the frame. Replacement should be considered if the bracket shows significant signs of wear or damage that cannot be repaired.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range includes components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles, reflecting its dedication to excellence and technological advancement.

Compatibility with Cummins Engines

This part is designed to fit seamlessly with several Cummins engine models, including the QSK95, CM2350, and K113 engines. It is crucial for maintaining the structural integrity and operational efficiency of these engines by securing the shock absorber in place.

Role in Engine Systems

The Shock Absorber Bracket 4382822 plays a significant role in various engine systems. In the context of an Engine Support system, it provides a stable mounting point for the shock absorber, ensuring the engine remains securely positioned within the vehicle’s chassis. When included in a Service Kit, it facilitates the easy installation of new shock absorbers, streamlining the maintenance process. In conjunction with a Vibration Isolator, it helps mitigate the transmission of vibrations from the engine to the vehicle’s chassis, leading to a smoother ride and reduced wear on other components.

Conclusion

The Shock Absorber Bracket 4382822 by Cummins is a critical component in the suspension and engine systems of commercial trucks. Its robust design, precise mounting points, and compatibility with various Cummins engines ensure optimal performance, stability, and longevity of the vehicle’s suspension and engine systems. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Reif, Konrad, ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.