4381975

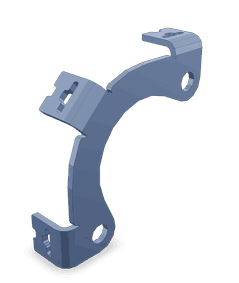

Wiring Retainer Bracket

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4381975 Wiring Retainer Bracket is a component designed for use in commercial trucks. Its primary role is to secure and organize the wiring within the truck’s electrical system. By doing so, it helps maintain the integrity and efficiency of the electrical connections, which is vital for the overall operation and safety of the vehicle 1.

Purpose and Function

The Wiring Retainer Bracket serves to hold and arrange the wiring in a truck’s electrical system. This organization prevents wires from becoming tangled or damaged, which could lead to electrical faults. By securing the wires, the bracket ensures that they remain in their intended positions, reducing the risk of wear and tear or accidental disconnections. This contributes to the consistent and reliable performance of the truck’s electrical components 2.

Key Features

The Cummins 4381975 Wiring Retainer Bracket is characterized by its robust design and the materials used in its construction. Typically made from durable plastics or metals, the bracket is engineered to withstand the vibrations and environmental conditions encountered in commercial trucking. Its design includes features that allow for easy attachment and adjustment, ensuring that it can accommodate various wiring configurations and remain secure over time 3.

Benefits

The use of the Wiring Retainer Bracket offers several advantages. It enhances wire management by keeping cables organized and protected, which can simplify troubleshooting and maintenance tasks. Additionally, by securing the wiring, the bracket helps reduce the likelihood of electrical faults that could arise from loose or damaged wires. This contributes to the safety and reliability of the truck’s electrical system, potentially reducing downtime and repair costs 4.

Installation and Compatibility

Proper installation of the Wiring Retainer Bracket is important to ensure it functions as intended. Installation guidelines typically include securing the bracket in a location that allows for easy access to the wiring while also providing sufficient protection from physical damage. Compatibility with various truck models and electrical systems is a consideration, ensuring that the bracket can be effectively utilized across different applications 5.

Maintenance and Troubleshooting

To ensure the optimal performance of the Wiring Retainer Bracket, regular maintenance is recommended. This may include checking the bracket for signs of wear or damage and ensuring that all wiring remains securely fastened. Common issues that may arise include loose connections or bracket displacement, which can often be addressed by re-securing the wiring or adjusting the bracket’s position 6.

Safety Considerations

When working with the Wiring Retainer Bracket, it is important to follow safety procedures to avoid electrical hazards. This includes ensuring that the truck’s electrical system is de-energized before beginning any work and using appropriate personal protective equipment. Proper handling and installation of the bracket are also crucial to prevent damage to the wiring or the bracket itself 7.

Regulatory Compliance

The Wiring Retainer Bracket must meet certain regulatory standards to ensure compliance with industry regulations and safety standards. This may involve adhering to specifications regarding material durability, electrical safety, and environmental resistance. Compliance with these standards helps ensure that the bracket performs reliably and safely within the truck’s electrical system 8.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has built a reputation for excellence in the manufacturing of automotive parts, including those for commercial trucks. The company’s focus on research and development ensures that its products, like the Wiring Retainer Bracket, meet the evolving needs of the industry 9.

Compatibility

The Wiring Retainer Bracket 4381975 is designed to be compatible with a range of Cummins engines, ensuring secure and organized wiring management. This bracket is essential for maintaining the integrity of the engine’s electrical system by keeping wiring neatly in place and preventing potential damage from movement or vibration.

Engine Compatibility

-

QSK50: The Wiring Retainer Bracket 4381975 is engineered to fit seamlessly with the QSK50 engine, providing a reliable solution for managing the complex wiring systems found in this high-performance engine.

-

CM2350: For the CM2350 engine, this bracket ensures that the wiring is securely fastened, reducing the risk of electrical faults and enhancing the overall reliability of the engine’s electrical components.

-

K108: The K108 engine also benefits from the use of the 4381975 Wiring Retainer Bracket. This part is crucial in maintaining the structural integrity of the engine’s wiring harness, ensuring that all connections remain stable and secure during operation.

By using the Cummins Wiring Retainer Bracket 4381975, technicians and operators can ensure that the electrical systems of these engines remain protected and functional, contributing to the overall performance and longevity of the engines 10.

Role of Part 4381975 Wiring Retainer Bracket in Engine Systems

The 4381975 Wiring Retainer Bracket is an essential component in organizing and securing various wiring systems within engine assemblies. Its primary function is to maintain the integrity and order of the wiring, ensuring that it does not interfere with other engine components or become damaged during operation 11.

Integration with the Aftercooler

In systems equipped with an aftercooler, the Wiring Retainer Bracket plays a significant role. It secures the wiring that runs alongside the aftercooler, preventing any potential chafing or abrasion that could occur from the vibrations and movements inherent in engine operation. This ensures that the wiring remains intact and functional, contributing to the overall efficiency and reliability of the aftercooler system 12.

Harness Organization

The bracket is instrumental in managing the engine harness. By providing a structured path for the harness, it reduces the risk of wire entanglement and ensures that the harness is positioned away from high-temperature areas and moving parts. This organization is vital for maintaining the harness’s durability and performance over time 13.

Electronic Control Module (ECM) Wiring

For the Electronic Control Module (ECM) wiring, the 4381975 bracket offers a secure mounting point. This is particularly important as the ECM wiring needs to be protected from environmental factors and mechanical stress. The bracket helps in maintaining a tidy and protected route for these sensitive wires, ensuring consistent and reliable communication between the ECM and various engine components 14.

Turbocharger Wiring

In turbocharged engine systems, the Wiring Retainer Bracket assists in securing the wiring associated with the turbocharger. This includes sensors and control wires that are critical for monitoring and regulating turbocharger performance. By keeping these wires organized and protected, the bracket helps in maintaining the turbocharger’s operational efficiency and longevity 15.

Conclusion

Overall, the 4381975 Wiring Retainer Bracket is a key component in ensuring that the wiring within engine systems remains organized, protected, and functional, contributing to the engine’s overall performance and reliability 16.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩ -

Cummins Inc. (n.d.). Service Manual (4358390).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.