This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

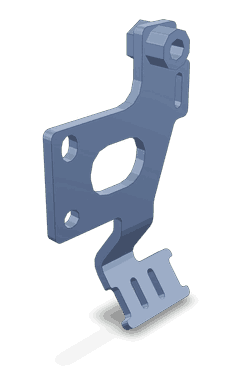

The Cummins 4381206 Wiring Retainer Bracket is a component designed to enhance the electrical system’s integrity in heavy-duty trucks. Its role is to secure and organize wiring harnesses, which are vital for the truck’s operation. This bracket ensures that the wiring remains protected and well-organized, contributing to the overall efficiency and reliability of the vehicle.

Purpose and Function

The Wiring Retainer Bracket serves to secure and organize the wiring harnesses within the electrical system of heavy-duty trucks. By holding the wires in place, it prevents them from coming into contact with moving parts or sharp edges, which could cause damage. This organization also aids in maintaining a tidy and accessible wiring layout, facilitating easier diagnosis and repair of electrical issues. The bracket contributes to the efficient operation of the truck by ensuring that the electrical connections remain intact and functional under various operating conditions.

Key Features

This part is constructed with durable materials to withstand the rigors of heavy-duty truck environments. It is designed with multiple mounting options to accommodate different truck configurations and engine types. The bracket’s design includes features that enhance its performance and longevity, such as corrosion-resistant coatings and robust attachment points. These attributes ensure that the bracket can endure the vibrations and harsh conditions typical of heavy-duty truck operations.

Benefits

The use of the 4381206 offers several advantages. It improves wire management by keeping the wiring harnesses organized and protected. This reduces the risk of electrical faults that can arise from damaged or loose wires. Additionally, the bracket enhances the overall reliability of the truck’s electrical system by ensuring that all connections remain secure and functional. This can lead to fewer downtimes and more consistent performance from the vehicle.

Installation and Compatibility

Proper installation of the Wiring Retainer Bracket involves securing it in the designated location using the appropriate tools and following the manufacturer’s guidelines. It is important to ensure that the bracket is correctly aligned and tightly fastened to provide the intended level of protection and organization for the wiring harnesses. The bracket is compatible with various Cummins engine models and has been designed to fit a range of truck makes and models, making it a versatile component for fleet management.

Maintenance and Troubleshooting

Regular maintenance checks for the 4381206 are recommended to ensure continued optimal performance. This includes inspecting the bracket for signs of wear or damage and ensuring that all wiring harnesses are securely held in place. Common issues that may arise include loose connections or bracket misalignment, which can be addressed by re-securing the bracket or adjusting the wiring as necessary. Prompt attention to these issues can prevent more significant electrical problems down the line.

Safety Considerations

When working with the 4381206, it is important to observe electrical safety practices. This includes ensuring that the truck’s electrical system is de-energized before beginning any work to prevent the risk of electric shock. Proper handling procedures should be followed to avoid damage to the bracket or the wiring harnesses. Additionally, all work should be conducted in accordance with the manufacturer’s guidelines and relevant safety standards to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leading manufacturer of diesel engines and a provider of high-quality automotive components. The company’s commitment to innovation and quality is evident in its range of products, including the 4381206, which is designed to meet the demanding requirements of heavy-duty truck operations 1.

Cummins Wiring Retainer Bracket 4381206 Compatibility

The Wiring Retainer Bracket 4381206, manufactured by Cummins, is designed to fit seamlessly within a range of their engine models. This part is crucial for maintaining the integrity of the engine’s electrical system by securing and organizing wiring harnesses.

QSK50 Engine Series

For the QSK50 engine series, the Wiring Retainer Bracket 4381206 is engineered to integrate with the engine’s complex wiring architecture. Given the QSK50’s robust design, this bracket ensures that all wiring is properly managed, reducing the risk of damage and enhancing overall engine reliability.

CM2350 Engine

In the CM2350 engine, the Wiring Retainer Bracket 4381206 plays a pivotal role in the engine’s electrical management system. This engine, known for its high performance and efficiency, benefits from the bracket’s ability to keep wiring organized and secure, contributing to the engine’s smooth operation.

K108 Engine

The K108 engine also utilizes the Wiring Retainer Bracket 4381206 to maintain an orderly and secure wiring system. This engine, designed for durability and power, relies on this bracket to prevent wiring issues that could lead to operational disruptions.

Grouping of Engines

When considering the QSK50, CM2350, and K108 engines together, it is evident that the Wiring Retainer Bracket 4381206 is a versatile component. Its design accommodates the specific wiring needs of each engine model, ensuring compatibility and functionality across different engine types.

Role of Part 4381206 Wiring Retainer Bracket in Engine Systems

The 4381206 is instrumental in maintaining the integrity and organization of the wiring systems within engine components. Specifically, it ensures that wires are securely held in place, reducing the risk of chafing, disconnection, or interference with other moving parts.

Integration with Nitrogen Oxide Sensor

In systems equipped with a Nitrogen Oxide (NOx) sensor, the 4381206 plays a significant role. The NOx sensor is vital for monitoring the levels of nitrogen oxides in the exhaust, which is essential for compliance with emissions regulations. The wiring retainer bracket secures the sensor’s wiring, ensuring it remains in the correct position and orientation. This stability is important for accurate sensor readings and reliable data transmission to the engine control unit (ECU).

Placement and Location

The location of the 4381206 is strategically chosen to maximize efficiency and protection. It is often positioned near high-traffic areas where wiring is prone to movement or stress. By securing the wiring in these areas, the bracket helps prevent potential damage that could lead to system failures or intermittent issues.

Conclusion

The 4381206 Wiring Retainer Bracket is a key component in ensuring the reliability and performance of engine systems, particularly in conjunction with sensors like the NOx sensor. Its role in securing and organizing wiring cannot be overstated, as it contributes to the overall stability and functionality of the engine’s electronic systems.

-

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.