This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

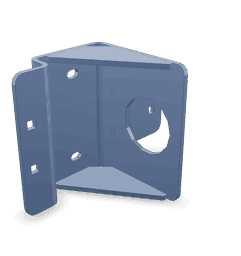

The Cummins 4322996 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses in heavy-duty truck systems. Its purpose is to maintain the integrity and efficiency of the electrical system by preventing damage to the wiring and ensuring that it remains in the correct position.

Purpose and Function

The Wiring Retainer Bracket plays a role in the electrical system of heavy-duty trucks by securing and organizing wiring harnesses. This helps prevent damage to the wiring from vibrations and other mechanical stresses that occur during operation. By keeping the wiring in an organized manner, it also ensures that the electrical system operates efficiently, reducing the risk of electrical faults 1.

Key Features

This Cummins part is designed with durability in mind, utilizing materials that can withstand the harsh conditions found in heavy-duty truck environments. It is engineered for ease of installation, allowing for quick and straightforward attachment to the truck’s frame. The bracket is compatible with a variety of truck models, ensuring versatility across different applications 2.

Benefits

Using the 4322996 Wiring Retainer Bracket provides several advantages. It improves wire management by keeping the wiring organized and secure, which can lead to a reduction in the risk of electrical faults. Additionally, it enhances the overall reliability of the truck’s electrical system by protecting the wiring from damage 3.

Installation Process

To install the Wiring Retainer Bracket, begin by identifying the correct location on the truck’s frame where the bracket will be attached. Ensure that the area is clean and free of any obstructions. Next, align the bracket with the mounting points and secure it in place using the provided fasteners. It is important to follow the manufacturer’s instructions carefully to ensure a proper installation. Common pitfalls to avoid include over-tightening the fasteners, which can damage the bracket or the frame, and not ensuring that the wiring is properly routed through the bracket.

Maintenance and Troubleshooting

To maintain the Wiring Retainer Bracket, regularly inspect it for signs of wear or damage. Ensure that the fasteners remain tight and that the wiring is securely held in place. If any issues are detected, such as loose fasteners or damaged wiring, address them promptly to prevent further complications. Common issues may include wiring becoming dislodged or the bracket showing signs of corrosion. In such cases, re-secure the wiring or replace the bracket as necessary.

Compatibility and Usage

The Cummins 4322996 Wiring Retainer Bracket is designed for use in various heavy-duty truck models. It is applicable in different truck configurations and environments, providing a versatile solution for wire management across a range of applications.

Safety Considerations

When working with the Wiring Retainer Bracket, it is important to follow safety guidelines to avoid electrical hazards. Ensure that the truck’s battery is disconnected before beginning any work on the electrical system. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself during installation and maintenance. Additionally, be mindful of the potential for sharp edges on the bracket and the frame, taking care to avoid injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its commitment to quality and innovation in the automotive and heavy-duty truck industry. The company’s products are designed to meet the demanding requirements of various applications, ensuring reliability and performance.

Role of Part 4322996 Wiring Retainer Bracket in Engine Systems

The 4322996 Wiring Retainer Bracket is an essential component that ensures the secure and organized placement of wiring within engine systems. Its application is particularly significant in the context of the following components:

Arrangement

In the arrangement of engine components, the Wiring Retainer Bracket plays a key role by maintaining the structural integrity of wiring. It prevents wires from becoming tangled or damaged, which is vital for the continuous and reliable operation of the engine.

Pressure Regulator Valve

When integrated with the Pressure Regulator Valve, the Wiring Retainer Bracket helps in keeping the electrical connections to the valve stable and protected. This ensures that the valve operates efficiently, maintaining the correct fuel pressure within the system.

Fuel Transfer Kit

Within the Fuel Transfer Kit, the Wiring Retainer Bracket secures the wiring that powers the transfer pump and other electrical components. This organization is important for the safe and effective transfer of fuel between tanks, minimizing the risk of electrical faults.

Fuel Transfer Right Hand Engine Kit

In the Fuel Transfer Right Hand Engine Kit, the bracket ensures that all wiring related to the right-hand engine’s fuel transfer system is neatly arranged. This is important for the system’s reliability, especially in dual-engine setups where synchronization is key.

Service Kit

During maintenance procedures outlined in the Service Kit, the Wiring Retainer Bracket facilitates easier access to wiring for inspection and repair. It ensures that wires are not only protected during operation but also readily accessible when servicing is required.

Conclusion

The Cummins 4322996 Wiring Retainer Bracket is a vital component in the maintenance and efficiency of heavy-duty truck electrical systems. By securing and organizing wiring harnesses, it prevents damage, reduces the risk of electrical faults, and enhances the overall reliability of the truck’s electrical system. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.