This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

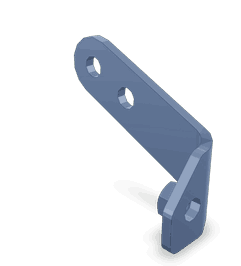

The Wiring Retainer Bracket, identified by part number 4306260, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This bracket plays a significant role in the electrical systems of commercial trucks, ensuring the efficient organization and secure placement of wiring harnesses. Cummins, known for its robust and reliable parts, provides this bracket as part of its comprehensive range of truck components designed to enhance vehicle performance and durability 1.

Purpose and Function

The Wiring Retainer Bracket serves a pivotal role in the electrical system of a truck. Its primary function is to organize and secure wiring harnesses, which are essential for the operation of various electrical components within the vehicle. By keeping the wires neatly arranged and firmly in place, the bracket helps prevent tangling, abrasion, and potential damage to the wires. This organization is vital for maintaining the integrity of the electrical system, ensuring consistent performance and reducing the likelihood of electrical faults 2.

Key Features

The design and material characteristics of the Wiring Retainer Bracket contribute to its effectiveness and longevity. Crafted from durable materials, the bracket is built to withstand the harsh conditions often encountered in commercial trucking. Its design facilitates ease of installation, allowing for quick and secure attachment to the vehicle’s frame. Additionally, the bracket is compatible with a wide range of truck models, making it a versatile component for fleet management and maintenance 3.

Benefits

Incorporating the Wiring Retainer Bracket into a truck’s electrical system offers several advantages. Improved wire management is one of the primary benefits, as it ensures that wires are neatly organized and less prone to damage. This organization reduces the risk of electrical faults, contributing to the overall safety and reliability of the truck’s electrical system. Furthermore, by securing the wiring harnesses, the bracket helps maintain the efficiency of the electrical connections, which is essential for the optimal operation of the vehicle.

Installation Process

Installing the Wiring Retainer Bracket involves a series of steps to ensure proper fitting and functionality. The process begins with identifying the correct location on the truck’s frame for bracket attachment. Necessary tools, such as wrenches and screwdrivers, should be prepared beforehand. Following the manufacturer’s guidelines, the bracket is secured in place, ensuring that it is firmly attached and aligned correctly. It is important to double-check the installation to confirm that the wiring harnesses are properly organized and secured within the bracket.

Maintenance and Troubleshooting

To ensure the longevity and effectiveness of the Wiring Retainer Bracket, regular maintenance is recommended. This includes periodic checks to ensure that the bracket remains securely attached and that the wiring harnesses are in good condition. Common issues may include loose connections or damaged wires, which can be identified through routine inspections. Basic troubleshooting involves securing any loose components and replacing damaged wires as necessary to maintain the integrity of the electrical system.

Safety Considerations

When working with electrical components and installing the Wiring Retainer Bracket, it is important to follow safety precautions to prevent accidents and ensure personal safety. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, and ensuring that the vehicle’s battery is disconnected before beginning any work on the electrical system. Additionally, it is crucial to follow the manufacturer’s instructions carefully to avoid damaging the bracket or the wiring harnesses during installation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product portfolio and commitment to excellence ensure that components like the Wiring Retainer Bracket meet the high standards required for commercial vehicle applications.

Wiring Retainer Bracket 4306260 Compatibility with Cummins Engines

The Wiring Retainer Bracket part number 4306260, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This bracket is crucial for securing and organizing the engine’s wiring, ensuring that electrical connections remain stable and protected from potential damage.

ISX12 and CM2350 Engines

The Wiring Retainer Bracket 4306260 is specifically engineered to fit the ISX12 and CM2350 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as commercial trucks and industrial machinery. The bracket’s design ensures that it can handle the rigorous demands of these engines, providing a secure mounting point for the wiring harness and preventing any unnecessary movement that could lead to wear and tear.

X102 Engine

Similarly, the X102 engine benefits from the use of the Wiring Retainer Bracket 4306260. This engine, typically found in agricultural and construction equipment, requires a reliable method to manage its wiring. The bracket’s precision fit ensures that the wiring is held firmly in place, reducing the risk of electrical issues that could arise from loose or damaged connections.

Grouping of Engines

When considering the ISX12, CM2350, and X102 engines together, it becomes evident that the Wiring Retainer Bracket 4306260 is a versatile component. Its design accommodates the unique requirements of each engine type while providing a consistent solution for wiring management. This compatibility highlights Cummins’ commitment to offering parts that enhance the functionality and longevity of their engines.

Role of Part 4306260 Wiring Retainer Bracket in Engine Systems

The part 4306260 Wiring Retainer Bracket is an essential component in the organization and protection of wiring systems within engine assemblies. It is specifically designed to secure and manage the harness and Electronic Control Module (ECM) wiring, ensuring that these vital components remain safely in place and are protected from potential damage.

Integration with Harness

The harness, a complex network of wires and cables, is responsible for transmitting electrical signals and power throughout the engine system. The Wiring Retainer Bracket plays a significant role in maintaining the structural integrity of the harness. By securing the harness in designated areas, it prevents chafing, abrasion, and potential short circuits that could arise from unsecured wiring. This ensures consistent and reliable electrical performance, which is fundamental for the engine’s operation.

Securing ECM Wiring

The ECM wiring is integral to the engine’s electronic control system, connecting the ECM to various sensors and actuators throughout the engine. The Wiring Retainer Bracket helps in organizing and securing these wires, reducing the risk of disconnection or damage. This is particularly important as the ECM relies on accurate and timely data from these connections to manage engine functions such as fuel injection, ignition timing, and emissions control. Proper securing of ECM wiring ensures that the ECM receives consistent signals, leading to optimized engine performance and efficiency.

Overall System Benefits

Incorporating the Wiring Retainer Bracket into engine systems offers several benefits. It enhances the durability and reliability of the wiring by protecting it from physical damage and environmental factors. Additionally, it contributes to a cleaner and more organized engine compartment, which can simplify maintenance and troubleshooting processes. The bracket also aids in vibration damping, further protecting the wiring from the dynamic forces present within an operating engine.

Conclusion

In summary, the part 4306260 Wiring Retainer Bracket is a key component in maintaining the integrity and functionality of the harness and ECM wiring within engine systems. Its role in securing and protecting these elements is vital for the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.