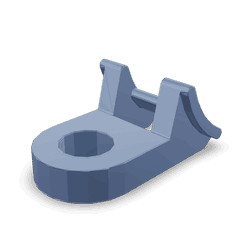

4295618

Wiring Retainer Bracket

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4295618 Wiring Retainer Bracket by Cummins is a component designed to enhance the functionality and reliability of heavy-duty truck electrical systems. This bracket serves a role in securing and organizing wiring harnesses, which are vital for the efficient operation of a truck’s electrical system.

Purpose and Function

The 4295618 Wiring Retainer Bracket plays a role in the electrical system by securing and organizing wiring harnesses. This function helps prevent damage to the wires from vibrations and other mechanical stresses that occur during operation. By maintaining the integrity and organization of the wiring, the bracket contributes to the overall efficiency and safety of the truck’s electrical system 1.

Key Features

The 4295618 Wiring Retainer Bracket is characterized by its robust design and material composition, which includes high-strength materials to ensure durability under demanding conditions. Its design facilitates ease of installation, allowing for quick and secure attachment to the truck’s frame. Additionally, the bracket is compatible with various wiring configurations, making it a versatile component for different truck models 2.

Benefits

The use of the 4295618 Wiring Retainer Bracket offers several advantages. It improves wire management by keeping the wiring harnesses organized and protected. This organization reduces the risk of electrical faults that can arise from damaged or misplaced wires. Furthermore, the bracket enhances the overall reliability of the truck’s electrical system by ensuring that the wiring remains secure and intact during operation 3.

Installation Process

Installing the 4295618 Wiring Retainer Bracket involves several steps to ensure it is securely and effectively placed within the truck’s electrical system. First, identify the appropriate location on the truck’s frame for mounting the bracket. Then, using the provided hardware, attach the bracket to the frame, ensuring it is level and firmly secured. Finally, route the wiring harnesses through the bracket, adjusting as necessary to ensure they are neatly organized and protected.

Maintenance and Troubleshooting

Regular inspection and maintenance of the 4295618 Wiring Retainer Bracket are recommended to ensure its continued effectiveness. Check for any signs of wear or damage to the bracket and the wiring harnesses. Common issues may include loose connections or damaged wires, which can be addressed by tightening connections or replacing damaged sections as needed.

Compatibility and Applications

The 4295618 Wiring Retainer Bracket is designed for use in various heavy-duty truck models. Its compatibility with different wiring configurations makes it suitable for a wide range of applications, ensuring that it can be effectively utilized across different makes and models of trucks.

Safety Considerations

When handling and installing the 4295618 Wiring Retainer Bracket, it is important to follow safety guidelines to avoid electrical hazards. Ensure that the truck’s electrical system is powered down before beginning installation. Adhere to manufacturer recommendations for installation and maintenance to ensure the safety and reliability of the electrical system.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its wide range of high-quality components. The company’s history of innovation and commitment to excellence has established Cummins as a trusted name among professionals. Components like the 4295618 Wiring Retainer Bracket exemplify Cummins’ dedication to providing reliable and durable solutions for the industry.

Cummins Engine Wiring Retainer Bracket 4295618

The Wiring Retainer Bracket 4295618, manufactured by Cummins, is a component in the electrical system of various Cummins engines. This part is designed to secure and organize the wiring harness, ensuring that electrical connections remain stable and protected from vibrations and environmental factors.

Application in Cummins Engines

QSK50 CM2150 K107

The Wiring Retainer Bracket 4295618 is compatible with the QSK50 CM2150 K107 engine. In this engine, the bracket helps maintain the integrity of the wiring harness, which is for the proper functioning of the engine’s electronic control unit (ECU) and other electrical components.

QSK95 CM2350 K111 and QSK95 CM2350 K113

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the Wiring Retainer Bracket 4295618 plays a similar role. These engines, known for their robust performance, require a reliable method to manage their complex wiring systems. The bracket ensures that the wiring harness is securely fastened, preventing any potential damage that could lead to electrical failures.

QST30 CM2350 T101 and QST30 CM552

In the QST30 CM2350 T101 and QST30 CM552 engines, the Wiring Retainer Bracket 4295618 is equally important. These engines, often used in heavy-duty applications, benefit from the bracket’s ability to keep the wiring harness in place. This is particularly crucial in environments where the engines are subjected to significant vibrations and harsh conditions, as it helps maintain the reliability and longevity of the electrical system.

By ensuring that the wiring harness is properly secured, the Wiring Retainer Bracket 4295618 contributes to the overall efficiency and reliability of these Cummins engines.

Conclusion

The 4295618 Wiring Retainer Bracket is an essential component in maintaining the integrity and organization of the wiring systems within engine assemblies. Its primary function is to secure and retain the wiring harness in place, ensuring that the wires remain neatly organized and protected from potential damage caused by engine vibrations or movement. This part plays a role in various applications, including the alarm system, electronic control module (ECM) wiring harness, and engine control module mounting, contributing to the overall reliability and efficiency of the electrical system.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.