4295617

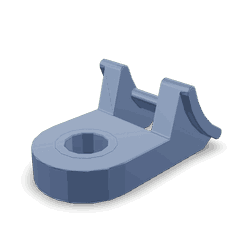

Wiring Retainer Bracket

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4295617 Wiring Retainer Bracket is a component designed to support and organize the wiring harnesses in heavy-duty truck electrical systems. Its role is significant as it ensures that the wiring remains secure, organized, and protected from potential damage, thereby contributing to the overall efficiency and reliability of the truck’s electrical system 1.

Purpose and Function

The Cummins Wiring Retainer Bracket serves to organize and secure wiring harnesses within the truck’s electrical system. By holding the wires in place, it prevents them from moving excessively, which can lead to wear and tear or accidental disconnections. This part plays a role in maintaining the integrity of the electrical connections and ensuring that the wires are less likely to come into contact with other components, which could cause short circuits or other electrical issues 2.

Key Features

The Cummins 4295617 Wiring Retainer Bracket is constructed from durable materials that are designed to withstand the harsh conditions often encountered in heavy-duty truck environments. Its design includes features that allow for easy attachment and adjustment, ensuring that it can accommodate various wiring configurations. The bracket is also designed to be corrosion-resistant, which enhances its longevity and performance in demanding applications 3.

Benefits

The use of the Cummins Wiring Retainer Bracket offers several benefits. It improves wire management by keeping the wiring organized and secure, which can simplify troubleshooting and maintenance tasks. Additionally, by reducing the risk of electrical faults due to wire chafing or disconnections, it contributes to enhanced system reliability. The bracket also helps protect the wiring from physical damage, which can extend the lifespan of the electrical components and reduce the likelihood of unexpected downtime.

Installation and Usage

Proper installation of the Cummins Wiring Retainer Bracket is crucial for its effective performance. It should be securely fastened in a location that allows for adequate wire management without impeding the operation of other components. Best practices include ensuring that the wiring is not overly tight or loose within the bracket, as this can affect its function and durability. Regular checks should be performed to ensure that the bracket remains in good condition and that the wiring is properly secured.

Maintenance and Troubleshooting

To maintain the Cummins Wiring Retainer Bracket, regular inspections should be conducted to check for signs of wear, corrosion, or damage. Cleaning the bracket and the surrounding area can help prevent the buildup of debris that could affect its performance. If wire chafing or bracket corrosion is detected, appropriate measures should be taken to address these issues promptly to prevent further damage to the electrical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its high-quality products and innovative solutions. The company’s extensive product offerings and commitment to customer satisfaction have established it as a trusted name in the industry.

Compatibility

The Cummins Wiring Retainer Bracket part number 4295617 is designed to be compatible with a variety of Cummins engine models. This bracket is essential for securing wiring harnesses and ensuring that electrical connections remain stable and protected within the engine compartment.

Compatible Engines

- ISX12 G CM2180 EJ

- ISX15 CM2350 X101

- QSK50 CM2150 K107

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK95 CM2350 K111

- QSK95 CM2350 K113

- QST30 CM2350 T101

- QST30 CM552

- VTA903 CM2250 V105

- X15 CM2350 X116B

- X15 CM2450 X134B

This wiring retainer bracket is a critical component for maintaining the integrity of the electrical system in these engines, ensuring that all connections remain secure and protected from the elements and mechanical stresses.

Role of Part 4295617 Wiring Retainer Bracket in Engine Systems

The Part 4295617 Wiring Retainer Bracket is an essential component in organizing and securing the wiring harness within various engine systems. Its primary function is to maintain the integrity and order of the wiring harness, ensuring that it does not interfere with other components or become damaged during engine operation.

Integration with Key Components

Aftercooler and Brackets

The Wiring Retainer Bracket is often positioned near the aftercooler and its associated brackets. It helps in securing the wiring harness that connects to the aftercooler, ensuring that the connections remain stable and do not get dislodged due to vibrations.

Air Heater Starting and Alarm Systems

For systems like the air heater starting and alarm, the Wiring Retainer Bracket plays a significant role. It organizes the wiring that powers these systems, preventing any potential short circuits or damage that could arise from loose wires.

Breather and Lubricating Oil Systems

In the crankcase breather and lubricating oil drain tube areas, the bracket ensures that the wiring harness is neatly routed. This is particularly important to avoid any oil contamination or damage to the wires from moving parts.

Compressor and Electronic Control Module

The Wiring Retainer Bracket is vital in the compressor area, where it secures the wiring harness connected to the electronic control module. This ensures reliable communication between the compressor and the engine control module, enhancing overall system performance.

Fuel Filter and Starting Aid Mounting

Near the fuel filter and starting aid mounting points, the bracket helps in organizing the wiring that supplies power to these components. This ensures that the fuel system operates efficiently without any electrical issues.

Plumbing and Sensor Connections

For plumbing components like the compressor coolant, fuel drain, and injector systems, the Wiring Retainer Bracket secures the wiring harness that connects to various sensors, such as the exhaust gas temperature sensor. This ensures accurate data transmission for engine monitoring systems.

Turbocharger and Water Transfer Tube

In the turbocharger and water transfer tube areas, the bracket ensures that the wiring harness is properly secured. This is essential for maintaining the turbocharger’s electronic controls and ensuring the water transfer tube’s plumbing system functions correctly.

Ignition and Engine Monitoring Systems

Finally, the Wiring Retainer Bracket plays a role in the ignition system by securing the wiring that connects to the ignition components. It also ensures that the engine monitoring system’s wiring remains intact, providing accurate and reliable data for engine diagnostics.

Conclusion

The Cummins 4295617 Wiring Retainer Bracket is a vital component in the maintenance and efficiency of heavy-duty truck electrical systems. Its role in securing and organizing wiring harnesses ensures the integrity of electrical connections, reduces the risk of faults, and protects wiring from damage. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are key to maximizing its benefits and ensuring the reliability of the truck’s electrical system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.