This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

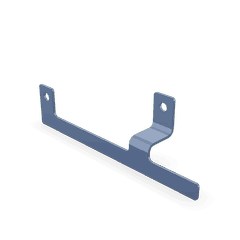

The Cummins 4100584 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses in commercial trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical system. By providing a structured environment for the wiring, it helps in preventing damage and ensuring that the electrical components function as intended.

Purpose and Function

The primary purpose of the Wiring Retainer Bracket is to secure and organize the wiring harnesses within a truck’s electrical system. This Cummins part plays a role in preventing wires from coming into contact with moving parts or sharp edges, which could lead to abrasions or cuts. By keeping the wires neatly arranged, it also aids in reducing the risk of electrical faults that could arise from wire tangling or short-circuiting. Furthermore, it contributes to the overall efficiency of the electrical system by ensuring that wires are positioned in a manner that facilitates optimal signal transmission and power distribution 1.

Key Features

The 4100584 is characterized by its robust design and the materials used in its construction. Typically made from durable plastics or metals, it is engineered to withstand the vibrations and harsh conditions encountered in commercial truck operations. Its design includes features such as mounting points and channels specifically tailored to accommodate and secure various sizes of wiring harnesses. These features enhance its performance and durability, ensuring long-term reliability in demanding environments 2.

Benefits

The installation of the Wiring Retainer Bracket offers several benefits. It improves wire management by providing a structured path for the wiring, which reduces the likelihood of damage and enhances the overall organization of the electrical system. This organization leads to a reduced risk of electrical faults, contributing to the safety and reliability of the truck’s operation. Additionally, by securing the wiring, it helps in maintaining the integrity of the electrical connections, which is crucial for the consistent performance of the truck’s electrical components.

Installation and Usage

Proper installation of the Wiring Retainer Bracket involves securing it in the designated location within the truck’s engine compartment. This process includes aligning the bracket with the mounting points and using the appropriate fasteners to ensure it is firmly in place. Once installed, the wiring harnesses can be routed through the bracket, following the designed channels and securing them as needed. To ensure optimal performance and longevity, it is important to periodically check the bracket and wiring for any signs of wear or damage and make adjustments or repairs as necessary.

Maintenance and Troubleshooting

Regular maintenance of the Wiring Retainer Bracket involves inspecting it for any signs of physical damage or wear. It is also important to ensure that the wiring remains securely fastened within the bracket and that there are no exposed wires that could lead to short circuits. Common issues may include bracket loosening or wiring displacement, which can be addressed by re-securing the bracket and repositioning the wiring as needed. Troubleshooting should involve a systematic approach to identifying the source of any electrical issues, with the bracket and wiring being among the first components to inspect.

Compatibility and Applications

The Cummins 4100584 Wiring Retainer Bracket is designed for use in specific types of trucks and engine models. Its applications span various commercial truck settings, where it plays a role in ensuring the electrical system’s reliability and efficiency. The bracket’s design and functionality make it suitable for integration into different truck models, contributing to the overall performance and safety of the vehicle.

Safety Considerations

When working with the Wiring Retainer Bracket, it is important to follow safety guidelines to ensure a safe working environment. This includes wearing appropriate personal protective equipment, ensuring the truck’s engine is off and cooled down before beginning any work, and following all manufacturer instructions for installation and maintenance. Additionally, it is crucial to be aware of the electrical system’s components and to work carefully around live wires to prevent electrical shocks or other injuries.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, including the Cummins 4100584 Wiring Retainer Bracket, which is designed to meet the demanding requirements of commercial truck applications.

Conclusion

The Cummins 4100584 Wiring Retainer Bracket is a vital component in the maintenance and efficiency of a truck’s electrical system. Its robust design, ease of installation, and the benefits it offers in terms of wire management and electrical system reliability make it an essential part for commercial truck operations. Regular maintenance and adherence to safety guidelines are crucial for ensuring the longevity and performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.