This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

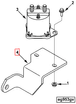

The 4078802 Magnetic Switch Bracket, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the engine and component manufacturing industry, produces this part to enhance the functionality and efficiency of commercial trucks. This bracket is integral to the operation of certain truck systems, ensuring that the vehicle performs optimally under various conditions.

Basic Concepts and Functionality

Magnetic switch brackets are designed to hold and secure switches or sensors in place using magnetic force. They operate by providing a stable and reliable mounting solution that can be easily attached and detached as needed. In automotive systems, these brackets are used to secure components that require precise positioning and easy access for maintenance or replacement. The magnetic property allows for quick installation and removal without the need for additional fasteners 1.

Purpose and Role in Truck Operation

The 4078802 Magnetic Switch Bracket serves a specific purpose in the operation of commercial trucks by securely mounting switches or sensors that are critical to the vehicle’s systems. It ensures that these components remain in the correct position, which is vital for the accurate functioning of the truck’s electronic systems. By providing a stable mounting solution, the bracket contributes to the overall reliability and efficiency of the truck, allowing for seamless operation of the systems it supports.

Key Features

The 4078802 Magnetic Switch Bracket features a robust design that incorporates high-quality materials to ensure durability and longevity. Its magnetic mounting system allows for easy installation and removal, which is particularly beneficial during maintenance or when adjustments are needed. The bracket is engineered to withstand the rigors of commercial truck operations, providing a secure hold even in demanding environments. Additionally, its design ensures compatibility with a range of switches and sensors, making it a versatile component for various applications.

Benefits

Using the 4078802 Magnetic Switch Bracket offers several advantages. Its magnetic mounting system simplifies the installation process, reducing the time and effort required compared to traditional fastening methods. The bracket’s durable construction ensures long-lasting performance, minimizing the need for frequent replacements. Additionally, its design allows for easy access to mounted components, facilitating maintenance and repairs. The bracket’s compatibility with a wide range of switches and sensors makes it a cost-effective solution for commercial truck operators.

Installation Process

Installing the 4078802 Magnetic Switch Bracket involves several steps to ensure proper attachment and functionality. Begin by identifying the location where the bracket will be mounted. Ensure the surface is clean and free of any debris that could interfere with the magnetic attachment. Align the bracket with the designated mounting area and press it firmly into place. Verify that the bracket is securely attached by gently attempting to lift it. Once confirmed, proceed to mount the switch or sensor onto the bracket. Use any provided tools or accessories to complete the installation, following safety guidelines to prevent injury or damage.

Troubleshooting Common Issues

Common issues with the 4078802 Magnetic Switch Bracket may include difficulty in attachment, detachment, or securing the switch or sensor. If the bracket does not attach securely, check the mounting surface for cleanliness and ensure there are no obstructions. If detachment is problematic, gently rock the bracket back and forth to break the magnetic hold before lifting. For issues with securing the switch or sensor, verify that it is properly aligned and seated on the bracket. Consulting the manufacturer’s guidelines or seeking professional assistance can provide further solutions to any encountered problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 4078802 Magnetic Switch Bracket, regular maintenance is recommended. Inspect the bracket and its mounting surface for any signs of wear, corrosion, or damage. Clean the bracket and surface as needed to remove dirt, grime, or other contaminants that could affect the magnetic attachment. Check the alignment and security of any mounted switches or sensors, ensuring they are functioning correctly. Following these maintenance routines will help maintain the bracket’s effectiveness and contribute to the overall reliability of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and components designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence is evident in its continuous investment in research and development, ensuring that its products deliver superior performance and durability.

Magnetic Switch Bracket 4078802 in Cummins Engines

The Magnetic Switch Bracket 4078802, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the operation of the engine’s ignition system, ensuring that the magnetic switch is properly positioned and secured.

Application in Specific Engine Models

6B5.9

The 6B5.9 engine benefits from the precise alignment and secure mounting provided by the Magnetic Switch Bracket 4078802. This bracket ensures that the magnetic switch operates correctly, which is essential for the engine’s ignition timing and overall performance.

QSB5.9 CM850 and QSB6.7 M CM2250

In the QSB5.9 CM850 and QSB6.7 M CM2250 engines, the Magnetic Switch Bracket 4078802 plays a similar role. These engines, known for their robust performance and reliability, depend on this bracket to maintain the integrity of the ignition system. The bracket’s design allows for precise positioning, which is crucial for the magnetic switch to function effectively.

Importance of the Magnetic Switch Bracket

The Magnetic Switch Bracket 4078802 is essential for the following reasons:

- Secure Mounting: It ensures that the magnetic switch is securely attached to the engine, preventing any movement that could disrupt the ignition process.

- Alignment: Proper alignment of the magnetic switch is critical for accurate timing and efficient engine operation.

- Durability: The bracket is designed to withstand the rigors of engine operation, ensuring long-term reliability and performance.

By integrating the Magnetic Switch Bracket 4078802 into these engines, Cummins ensures that the ignition system operates smoothly, contributing to the overall efficiency and longevity of the engine.

Role of Part 4078802 Magnetic Switch Bracket in Engine Systems

In the orchestration of engine systems, the 4078802 Magnetic Switch Bracket serves as a pivotal component, ensuring seamless integration and operation of various subsystems. This bracket is instrumental in the electric starting system, where it securely mounts the magnetic switch, facilitating the connection between the battery and the starter motor.

When the ignition is turned, the magnetic switch, held firmly by the bracket, engages the starter motor, initiating the engine’s startup sequence. This action is fundamental for the engine’s operation, as it translates the electrical energy from the battery into mechanical energy to crank the engine.

Moreover, the 4078802 Magnetic Switch Bracket plays a significant role in the accessories system. It ensures that the magnetic switch is positioned optimally to manage the flow of electricity to various engine accessories. This includes components like the fuel pump, ignition system, and other electrical accessories that require a consistent and reliable power supply to function correctly.

The bracket’s design and placement are tailored to accommodate the specific requirements of the magnetic switch, enhancing the overall efficiency and reliability of the engine’s electrical system. Its integration into the engine system underscores the importance of precise component interaction in achieving optimal engine performance.

Conclusion

The 4078802 Magnetic Switch Bracket is a vital component in the operation of commercial trucks and Cummins engines. Its robust design, magnetic mounting system, and compatibility with various switches and sensors make it an essential part for ensuring the reliability and efficiency of truck and engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall performance and longevity of the vehicle.

-

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.