This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

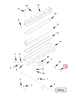

The Cummins 4068693 Switch Bracket is a component designed for use in commercial trucks. Its primary role is to facilitate the secure mounting and organization of electrical switches within the vehicle’s electrical system. By providing a structured framework for switch placement, it contributes to the efficient operation and maintenance of the truck’s electrical components 1.

Purpose and Functionality

The 4068693 Switch Bracket serves a function in the electrical system of a truck by securing and organizing electrical switches. This bracket ensures that switches are held firmly in place, reducing the risk of disconnection or damage during operation. It also aids in the systematic arrangement of switches, which is beneficial for both the driver’s ease of use and for maintenance personnel during servicing 2.

Key Features

The design of the 4068693 Switch Bracket incorporates several features that enhance its performance and durability. Constructed from high-quality materials, it is built to withstand the rigors of commercial truck environments. Its design allows for easy attachment and detachment of switches, facilitating quick changes or repairs. Additionally, the bracket is engineered to provide a stable platform for switches, ensuring consistent electrical connections 3.

Benefits

Utilizing the 4068693 Switch Bracket offers several advantages. It improves the organization of electrical components within the truck, making it easier for drivers to locate and operate switches. This organization also enhances safety by ensuring that all electrical connections are secure and properly managed. Furthermore, the bracket simplifies maintenance tasks by providing a clear and accessible layout for electrical switches 4.

Installation Process

Installing the 4068693 Switch Bracket involves several steps to ensure proper setup. Begin by identifying the location where the bracket will be mounted. Use the appropriate tools to secure the bracket to the designated area, ensuring it is level and firmly attached. Once the bracket is in place, electrical switches can be mounted onto it, following the manufacturer’s guidelines for secure attachment. It is important to verify all connections are secure and that the switches operate correctly after installation 5.

Maintenance and Troubleshooting

To maintain the 4068693 Switch Bracket, regular inspections should be conducted to ensure all switches are securely mounted and that there are no signs of wear or damage to the bracket itself. Common issues may include loose connections or damaged switches, which can often be resolved by tightening connections or replacing faulty components. For more complex problems, consulting the manufacturer’s guidelines or a professional technician is recommended 6.

Compatibility and Usage

The 4068693 Switch Bracket is designed for use in specific types of trucks and electrical systems. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. Usage guidelines provided by the manufacturer should be followed to maximize the effectiveness and longevity of the bracket 7.

Safety Considerations

When installing or maintaining the 4068693 Switch Bracket, it is crucial to adhere to electrical safety practices. This includes ensuring the truck’s electrical system is powered down during installation or maintenance to prevent electrical shocks. Additionally, all work should be conducted in a well-ventilated area, and appropriate personal protective equipment should be worn 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s products are known for their reliability, efficiency, and performance, making them a preferred choice for commercial vehicle operators worldwide 9.

Cummins Switch Bracket 4068693 Compatibility

The Cummins Switch Bracket part number 4068693 is designed to fit seamlessly with a variety of engine models. This part is integral to the proper functioning of the engine’s electrical and mechanical systems. Below is a detailed overview of the engines with which this switch bracket is compatible:

QST30 Series

The QST30 series engines benefit from the robust design of the 4068693 switch bracket. This bracket ensures that the electrical switches are securely mounted and properly aligned, which is crucial for maintaining the engine’s operational integrity. The QST30 engines, known for their reliability and performance, are often used in heavy-duty applications, and the switch bracket plays a role in ensuring that these engines run smoothly.

CM552 Series

Similarly, the CM552 series engines are designed to work efficiently with the 4068693 switch bracket. This bracket provides the necessary support and alignment for the switches, which is essential for the engine’s electrical systems. The CM552 engines are also used in various demanding applications, and the switch bracket helps to maintain the engine’s performance and reliability.

Grouping of Compatible Engines

The 4068693 switch bracket is not limited to individual models but is compatible with a range of Cummins engines. This compatibility is due to the standardized design and manufacturing processes used by Cummins, ensuring that the switch bracket fits well with multiple engine models. The grouping of compatible engines includes:

- QST30 Series: QST30, QST30-1, QST30-2

- CM552 Series: CM552, CM552-1, CM552-2

By ensuring that the switch bracket is compatible with these engine series, Cummins maintains a high level of consistency and reliability across its engine lineup. This compatibility allows for easier maintenance and repair, as technicians can use the same switch bracket across multiple engine models.

Role of Part 4068693 Switch Bracket in Engine Systems

The Part 4068693 Switch Bracket is an integral component in the orchestration of various engine systems, facilitating the seamless interaction between the Aftercooler, Manifold, and Air Intake.

Integration with the Aftercooler

In engine systems equipped with an Aftercooler, the Switch Bracket plays a role. It securely mounts switches that monitor the temperature and pressure within the Aftercooler. These switches send data to the engine control unit (ECU), allowing for precise adjustments to maintain optimal cooling and efficiency.

Functionality within the Manifold

When integrated into the Manifold system, the Switch Bracket supports switches that detect pressure variations. This data is essential for the ECU to make real-time adjustments to fuel injection and air-fuel ratio, ensuring the engine operates within its performance parameters while minimizing emissions.

Contribution to the Air Intake System

In the Air Intake system, the Switch Bracket is employed to mount sensors that measure the volume and temperature of the incoming air. This information is critical for the ECU to calculate the correct amount of fuel to inject, thereby optimizing combustion efficiency and power output.

Overall, the Part 4068693 Switch Bracket enhances the functionality and efficiency of these engine components by providing a stable platform for essential monitoring switches.

Conclusion

The Cummins 4068693 Switch Bracket is a vital component in the electrical systems of commercial trucks, ensuring the secure mounting and organization of electrical switches. Its design and features contribute to the efficient operation and maintenance of the truck’s electrical components, enhancing safety and simplifying maintenance tasks. Compatibility with various Cummins engine models further underscores its importance in maintaining the performance and reliability of these engines.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 3666260.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 3666260.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 3666260.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 3666260.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 3666260.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 3666260.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.