4067011

Wiring Retainer Bracket

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

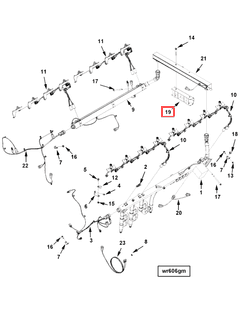

The Cummins 4067011 Wiring Retainer Bracket is a component designed to enhance the electrical system’s organization and security in heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical network, ensuring that wiring harnesses are properly secured and managed 1.

Purpose and Function

The Wiring Retainer Bracket serves to secure and organize the wiring harnesses within a truck’s electrical system. By holding the wires in place, it prevents them from moving excessively, which could lead to wear, damage, or disconnection. This bracket contributes to the overall stability and reliability of the electrical connections, ensuring that power is consistently and safely distributed throughout the vehicle 2.

Key Features

This Cummins part is crafted from durable materials, designed to withstand the harsh conditions often encountered in heavy-duty truck operations. Its design includes features that allow for easy attachment and adjustment, ensuring a secure fit around the wiring harnesses. The bracket’s construction is robust, providing long-lasting performance and resistance to environmental factors such as vibration, moisture, and temperature fluctuations 3.

Benefits

Utilizing the Wiring Retainer Bracket offers several advantages. It improves wire management by keeping the harnesses organized and protected, which can reduce the risk of electrical faults. This organization contributes to the safety and reliability of the truck’s electrical system, potentially lowering the likelihood of downtime due to electrical issues. Additionally, by securing the wiring, the bracket helps maintain the efficiency of the electrical connections, supporting the overall performance of the vehicle.

Installation and Usage

Installing the 4067011 involves securing it around the designated wiring harnesses. The process requires ensuring that the bracket is correctly aligned and tightened to hold the wires firmly in place without causing damage. Tools such as wrenches may be necessary for proper installation. It’s important to follow the manufacturer’s guidelines for placement to ensure the bracket effectively serves its purpose.

Maintenance and Troubleshooting

Regular maintenance of the Wiring Retainer Bracket includes checking for any signs of wear or damage and ensuring that the wiring harnesses remain securely fastened. Common issues may include loosening of the bracket or damage to the wiring, which can be addressed by retightening the bracket or repairing the wiring as necessary. Troubleshooting should involve a thorough inspection of the electrical system to identify any potential problems early.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a trusted name among professionals in the automotive and heavy-duty truck sectors.

Role of 4067011 Wiring Retainer Bracket in Engine Systems

This part is an essential component in organizing and securing the wiring within engine systems. It ensures that the harness and electronic control module (ECM) wiring remain neatly arranged and protected from potential damage caused by engine vibrations or heat.

When integrating the Wiring Retainer Bracket into an engine system, it is positioned to hold the wiring harness in place. This bracket prevents the wires from coming into contact with moving parts or hot surfaces, thereby reducing the risk of wear, fraying, or melting.

In systems where the ECM is utilized, the bracket plays a significant role in maintaining the integrity of the ECM wiring. By securing these wires, the bracket helps ensure consistent and reliable communication between the ECM and various engine components. This is particularly important for systems that rely on precise data transmission for optimal performance.

Additionally, the Wiring Retainer Bracket contributes to the overall organization within the engine compartment. It allows for easier access during maintenance or repairs, as the wiring is kept tidy and out of the way. This organization also aids in troubleshooting, as technicians can more easily trace wires and identify potential issues.

Conclusion

In summary, the 4067011 Wiring Retainer Bracket is a key component in maintaining the functionality and reliability of engine systems by securing and organizing critical wiring.

-

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.