This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

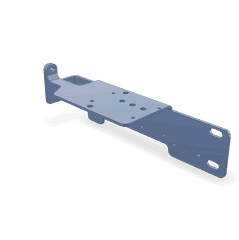

The Magnetic Switch Bracket, identified by Part #4019678, is a component manufactured by Cummins, a well-established name in the automotive industry. This bracket serves a specific purpose in the operation of commercial trucks, contributing to the efficient functioning of various systems. Cummins, known for its commitment to innovation and quality, produces this part to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts

Understanding the Magnetic Switch Bracket requires a grasp of the fundamental principles behind magnetic switches. These switches operate based on the principles of magnetism, where a magnetic field is used to actuate a switch mechanism. In automotive systems, magnetic switches are employed for various applications, including controlling electrical circuits, activating relays, and managing other functions. The Magnetic Switch Bracket plays a role in housing and securing these switches, ensuring they function correctly within the truck’s electrical system 2.

Purpose and Function

The Magnetic Switch Bracket is designed to support and secure magnetic switches within a truck’s electrical system. It plays a role in the operation of a truck by providing a stable mounting point for these switches, which are integral to the control of various electrical components. The bracket ensures that the switches are correctly positioned and protected, allowing them to interact efficiently with other components to maintain optimal truck performance. This interaction is vital for the reliable operation of systems such as lighting, engine management, and auxiliary equipment.

Key Features

The Magnetic Switch Bracket is characterized by several key features that enhance its functionality. Its design is robust, constructed from durable materials to withstand the harsh conditions typical of commercial truck environments. The bracket is engineered to provide a secure fit for magnetic switches, ensuring they remain in place and operate correctly. Additionally, it features precise mounting points and alignment guides to facilitate easy and accurate installation. These attributes contribute to the overall reliability and performance of the truck’s electrical system.

Benefits

The incorporation of the Magnetic Switch Bracket into a truck’s system offers several advantages. One of the primary benefits is improved reliability, as the secure mounting of magnetic switches reduces the risk of electrical failures. Ease of installation is another significant advantage, as the bracket’s design allows for straightforward integration into the truck’s existing system. Furthermore, the durability of the bracket can lead to potential cost savings for fleet operators by reducing the need for frequent replacements or repairs.

Installation and Integration

Proper installation of the Magnetic Switch Bracket is crucial for ensuring its effective operation. Before installation, it is important to verify that the truck’s electrical system is compatible with the bracket and that all necessary components are in place. The installation process involves securely mounting the bracket in the designated location, ensuring that it is level and firmly attached. Once installed, the magnetic switches can be positioned within the bracket, followed by connecting them to the appropriate electrical circuits. Careful attention to these steps will ensure the bracket integrates seamlessly into the truck’s system.

Troubleshooting and Maintenance

Common issues that may arise with the Magnetic Switch Bracket include loose connections, damage to the bracket, or malfunction of the magnetic switches. Troubleshooting these issues involves inspecting the bracket and switches for signs of wear or damage, ensuring all connections are secure, and verifying that the switches are operating correctly. Regular maintenance, such as cleaning the bracket and switches and checking for corrosion, can help prevent issues and ensure longevity and optimal performance. Promptly addressing any problems that arise will help maintain the efficiency of the truck’s electrical system.

Safety Considerations

When working with the Magnetic Switch Bracket, it is important to observe several safety practices. These include ensuring the truck’s electrical system is de-energized before beginning any installation or maintenance work to prevent electrical shocks. Additionally, using the appropriate tools and personal protective equipment (PPE) is crucial to protect against injuries. Following the manufacturer’s guidelines for installation and maintenance will help ensure safe and effective operation of the bracket.

Cummins Overview

Cummins has a long-standing reputation in the automotive industry for producing high-quality components for commercial trucks. Founded with a commitment to innovation and excellence, Cummins has consistently delivered reliable and durable parts that meet the rigorous demands of heavy-duty applications. Their focus on quality and performance has made them a trusted name among fleet operators and manufacturers alike, ensuring that their components, including the Magnetic Switch Bracket, contribute to the efficient and reliable operation of commercial trucks.

Magnetic Switch Bracket 4019678 in Cummins Engines

The Magnetic Switch Bracket 4019678, manufactured by Cummins, is a critical component in several Cummins engine models. This part plays a pivotal role in the engine’s operation by ensuring the magnetic switch is correctly positioned and secured.

Application in Specific Cummins Engines

6B5.9 Engine Series

In the 6B5.9 engine series, the Magnetic Switch Bracket 4019678 is integral to the engine’s ignition system. It ensures that the magnetic switch, which is responsible for triggering the ignition coil, is accurately aligned and held in place. This precision is crucial for maintaining optimal engine performance and reliability.

Other Cummins Engine Models

While the 6B5.9 series is a primary focus, the Magnetic Switch Bracket 4019678 is also compatible with various other Cummins engine models. Its design and functionality remain consistent across different engine types, ensuring that the magnetic switch operates efficiently and reliably.

Importance of the Magnetic Switch Bracket

The Magnetic Switch Bracket 4019678 is essential for several reasons:

- Alignment and Stability: It ensures that the magnetic switch is correctly aligned with the engine’s rotating components, which is vital for accurate timing and ignition.

- Durability: Constructed from high-quality materials, this bracket withstands the harsh conditions within the engine compartment, including high temperatures and vibrations.

- Ease of Installation: Designed for straightforward installation, it simplifies maintenance and repair processes, reducing downtime for engine servicing.

Compatibility and Usage

The Magnetic Switch Bracket 4019678 is engineered to fit seamlessly with the specified Cummins engines. Its compatibility extends across various models, making it a versatile component for different engine applications. Technicians and mechanics can rely on this bracket to provide a secure and reliable mounting solution for the magnetic switch.

Role of Part 4019678 Magnetic Switch Bracket in Engine Systems

The 4019678 Magnetic Switch Bracket is an integral component in the orchestration of various engine systems, ensuring seamless operation and efficiency.

In the context of electric starting systems, the Magnetic Switch Bracket securely mounts the magnetic switch, which is responsible for engaging the starter motor. This bracket ensures a stable connection, allowing the starter motor to function correctly when the ignition is activated.

For instrument systems, the bracket plays a supportive role by providing a reliable mounting point for sensors and other instrumentation components. This stability is essential for accurate readings and consistent performance of the engine’s monitoring systems.

When considering engine components, the Magnetic Switch Bracket contributes to the overall structural integrity of the engine bay. By offering a robust attachment point for the magnetic switch, it helps maintain the precise alignment and operation of the starting mechanism, which is vital for the engine’s reliable start-up process.

In accessories integration, the bracket facilitates the addition of various aftermarket or supplementary components that may require a secure mounting solution near the engine’s starting system. This versatility enhances the engine’s functionality and adapts to different user needs.

Overall, the 4019678 Magnetic Switch Bracket is a foundational element that supports the efficient and reliable operation of multiple engine systems, ensuring that each component functions harmoniously within the engine’s complex network.

Conclusion

The Magnetic Switch Bracket, part number 4019678, is a critical component in the operation of commercial trucks and Cummins engines. Its role in securing and aligning magnetic switches ensures the reliable and efficient functioning of various engine systems. The robust design, ease of installation, and compatibility with multiple engine models make this Cummins part a valuable asset for fleet operators and technicians. Regular maintenance and adherence to safety practices are essential for maximizing the performance and longevity of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.