This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

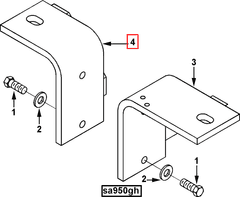

The Marine Gear Bracket 4019393, manufactured by Cummins, is a component designed for use in commercial trucks. It is integral to the functionality of heavy-duty trucks, particularly in marine applications. Marine gear brackets serve as a vital link in the mechanical systems of trucks, ensuring the proper operation and integration of various components.

Basic Concepts of Marine Gear Brackets

Marine gear brackets are components that facilitate the connection and alignment of gears within a mechanical system. They play a role in maintaining the structural integrity and operational efficiency of the gear system by providing a stable mounting point 1. This part is specifically designed to meet the demands of heavy-duty applications, offering a robust solution for the mounting and alignment of marine gears.

Role and Function in Truck Operation

This Cummins part contributes to the operation of a truck by ensuring the precise alignment and secure mounting of marine gears. This alignment is crucial for the efficient transfer of power within the drivetrain system. By maintaining the correct positioning of gears, the bracket helps to enhance the overall efficiency and reliability of the truck’s drivetrain, reducing the likelihood of mechanical failures and improving operational performance 2.

Key Features

The 4019393 is characterized by its durable material composition, which is designed to withstand the rigors of heavy-duty use. Its design incorporates elements that enhance its performance, such as precise machining for accurate gear alignment and robust construction for longevity. These features contribute to the bracket’s ability to support the demanding requirements of marine applications.

Benefits

Utilizing this part offers several benefits, including improved stability of the gear system, enhanced performance through precise alignment, and increased longevity due to its durable construction. These advantages contribute to the efficient operation and maintenance of the truck, reducing downtime and repair costs.

Installation and Compatibility

Proper installation of the Marine Gear Bracket involves ensuring it is correctly aligned and securely fastened to the truck’s frame or designated mounting point. Compatibility with various truck models and engine types is a consideration, as the bracket must be suited to the specific application to ensure optimal performance and integration within the truck’s mechanical system.

Troubleshooting and Maintenance

Common issues with this Cummins part may include misalignment or wear over time. Troubleshooting these issues involves inspecting the bracket for signs of damage or misalignment and making necessary adjustments or replacements. Regular maintenance, such as checking for secure fastening and inspecting for wear, can help ensure the longevity and optimal performance of the bracket 3.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive and commercial vehicle industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and components like the 4019393, Cummins has built a reputation for delivering reliable and high-performance solutions to its customers. The company’s focus on quality and innovation is evident in its product offerings, which are designed to meet the demanding requirements of various applications.

Cummins Marine Gear Bracket 4019393 Compatibility

The Cummins Marine Gear Bracket part number 4019393 is designed to fit seamlessly with a variety of Cummins marine engines. This bracket is a critical component in the engine’s gear assembly, ensuring proper alignment and secure mounting of the gear mechanism.

Engine Compatibility

-

6B5.9 Series: The 4019393 bracket is specifically engineered to fit the 6B5.9 series engines. This series is known for its robust performance and reliability in marine applications. The bracket’s design ensures that it can handle the stresses and vibrations inherent in marine environments, providing a stable and durable connection between the engine and the gear assembly.

-

Other Cummins Marine Engines: While the primary focus is on the 6B5.9 series, the 4019393 bracket is also compatible with other Cummins marine engines. This compatibility extends to various models within the Cummins marine engine lineup, ensuring that the bracket can be used across different engine configurations while maintaining its functionality and performance.

Installation and Usage

When installing the Cummins Marine Gear Bracket 4019393, it is essential to follow the manufacturer’s guidelines to ensure proper alignment and secure attachment. The bracket’s design allows for easy installation, with precise fitting to accommodate the specific engine model it is intended for.

Proper installation of the 4019393 bracket is crucial for the efficient operation of the engine’s gear assembly. It helps in maintaining the integrity of the gear mechanism, reducing wear and tear, and extending the overall lifespan of the engine components.

Importance of the Bracket

The Cummins Marine Gear Bracket 4019393 plays a vital role in the engine’s operation by ensuring that the gear assembly is correctly positioned and securely fastened. This is particularly important in marine environments where the engine is subjected to various stresses, including saltwater corrosion, high vibrations, and fluctuating temperatures.

By providing a reliable and durable connection, the 4019393 bracket helps maintain the performance and reliability of the engine, contributing to the overall efficiency and longevity of the marine power system.

Role of Part 4019393 Marine Gear Bracket in Engine Systems

The 4019393 is an essential component in the assembly and functionality of marine engine systems. It primarily interfaces with the support and power train components to ensure efficient operation and structural integrity.

Integration with Support Components

The Marine Gear Bracket is designed to securely attach to various support structures within the engine system. This includes mounting brackets, chassis elements, and other foundational components that provide the necessary stability for the engine. By firmly anchoring the gear assembly, the bracket prevents undue movement and vibration, which can lead to wear and potential failure of other engine parts.

Interaction with Power Train Components

In the power train, the Marine Gear Bracket plays a significant role in aligning and supporting the gear assembly. It ensures that the gears are correctly positioned relative to the engine’s drive shaft and transmission components. This precise alignment is vital for the smooth transfer of power from the engine to the propulsion system. The bracket also helps in managing the load distribution across the gear teeth, reducing the risk of gear slippage or damage during operation.

Enhanced System Performance

By providing a stable and well-aligned platform for the gear assembly, the Marine Gear Bracket contributes to the overall performance and reliability of the engine system. It allows for consistent power delivery, improved fuel efficiency, and reduced maintenance requirements. The bracket’s robust design also enhances the durability of the engine components, ensuring long-term operation under various marine conditions.

Conclusion

The 4019393 Marine Gear Bracket is a critical component in the operation and maintenance of heavy-duty trucks, particularly in marine applications. Its role in ensuring the precise alignment and secure mounting of marine gears contributes to the efficient transfer of power within the drivetrain system. The bracket’s durable construction and precise machining enhance the overall efficiency and reliability of the truck’s drivetrain, reducing the likelihood of mechanical failures and improving operational performance. Proper installation and regular maintenance of this part are essential for ensuring its longevity and optimal performance within the truck’s mechanical system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.