This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

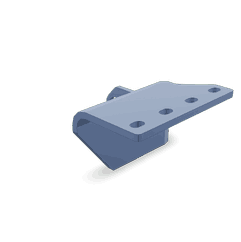

The Cummins 4017623 Magnetic Switch Bracket is a component designed for use in heavy-duty trucks. It serves a specific function within the truck’s electrical system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance can provide valuable insights into the complexities of truck systems and the importance of each component within them.

Basic Concepts and Functionality

Magnetic switch brackets are integral to the operation of various electrical components in trucks. They function by securely holding magnetic switches in place, ensuring consistent and reliable performance. These brackets play a role in maintaining the alignment and stability of the switches, which are often responsible for controlling critical systems such as lighting, engine components, and other electrical circuits. The magnetic properties of the bracket allow for a secure and vibration-resistant mounting solution, which is particularly important in the rugged environment of heavy-duty trucking 1.

Purpose of the Cummins 4017623 Magnetic Switch Bracket

The Cummins 4017623 Magnetic Switch Bracket is designed to hold magnetic switches in the appropriate position within a truck’s electrical system. It interacts with other components by providing a stable platform for the switches, which may control various functions such as engine start systems, lighting, and other electrical circuits. The bracket ensures that the switches remain in the correct orientation and are protected from physical damage or displacement due to vibrations or impacts 2.

Key Features

The Cummins 4017623 Magnetic Switch Bracket is characterized by its robust design and the materials used in its construction. It is typically made from durable metals that offer resistance to corrosion and physical stress. The bracket’s magnetic properties are a key feature, allowing it to securely hold the switch in place without the need for additional fasteners. This design not only simplifies the installation process but also enhances the reliability of the switch’s operation 3.

Benefits

The use of the Cummins 4017623 Magnetic Switch Bracket offers several advantages. It contributes to improved efficiency by ensuring that the magnetic switch operates within the correct parameters. The bracket’s design enhances the reliability of the switch, reducing the likelihood of malfunctions due to displacement or damage. Additionally, the bracket’s durability and resistance to environmental factors contribute to the longevity of the switch and the overall electrical system 4.

Installation and Integration

Proper installation of the Cummins 4017623 Magnetic Switch Bracket is important for ensuring its effectiveness. It should be mounted in a location that provides easy access for maintenance while also offering protection from physical damage. The installation process may require the disconnection of certain electrical components, and it is important to follow the manufacturer’s guidelines to ensure a secure and proper fit. Integration within the truck’s system should consider the bracket’s interaction with other electrical components to avoid interference or damage 5.

Troubleshooting and Maintenance

Common issues with the Cummins 4017623 Magnetic Switch Bracket may include displacement of the switch, corrosion of the bracket, or failure of the magnetic properties. Troubleshooting should begin with a visual inspection of the bracket and switch for any signs of damage or misalignment. Maintenance tips include regular cleaning to remove dirt and debris, inspection for signs of corrosion, and ensuring that the bracket remains securely mounted. Any issues should be addressed promptly to prevent further complications within the truck’s electrical system 6.

Safety Considerations

When working with the Cummins 4017623 Magnetic Switch Bracket, it is important to observe certain safety guidelines. This includes ensuring that the truck’s electrical system is de-energized before beginning any work to prevent the risk of electric shock. Additionally, proper personal protective equipment should be worn to protect against any potential hazards. It is also important to follow the manufacturer’s instructions and guidelines to ensure safe and effective installation and maintenance of the bracket 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient components for the automotive and heavy-duty truck industries. The company’s focus on research and development ensures that its products, including the Cummins 4017623 Magnetic Switch Bracket, meet the high standards required for modern truck systems 8.

Compatibility with Cummins Engines

The Cummins 4017623 Magnetic Switch Bracket is compatible with a variety of Cummins engines, ensuring the proper functioning of the engine’s ignition system. This bracket is essential for the correct operation of the magnetic switch.

K-Series Engines

- K19

- K38

- K50

The bracket is compatible with the K-Series engines, including the K19, K38, and K50, which are known for their robust design and are often used in various industrial and agricultural applications.

KTA19GC

This bracket also fits the KTA19GC engine, a variant of the K-Series engines, often used in generator sets and other heavy-duty applications.

N14 MECHANICAL

The Cummins 4017623 is also suitable for the N14 MECHANICAL engine, a high-performance engine often used in heavy-duty trucks and industrial applications.

NH/NT 855

This bracket is compatible with the NH/NT 855 engine, part of the Cummins NH/NT series, known for its reliability and efficiency in various applications.

QSK45 CM500

The Cummins 4017623 fits the QSK45 CM500 engine, part of the QSK series, designed for heavy-duty applications such as power generation and marine use.

QSK50 CM2150 MCRS and QSK50 CM2350 K108

This bracket is also compatible with the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines. These engines are part of the QSK series and are known for their high power output and reliability in demanding applications.

QSK60 CM500 and QSK60 CM850 MCRS

The Cummins 4017623 fits the QSK60 CM500 and QSK60 CM850 MCRS engines, which are part of the QSK series and are used in heavy-duty applications such as power generation and marine use.

QSK78 CM500

This bracket is compatible with the QSK78 CM500 engine, part of the QSK series and designed for high-power applications.

V28

Lastly, the Cummins 4017623 fits the V28 engine, part of the Cummins V-Series engines, known for their durability and performance in various applications.

Role in Engine Systems

The Cummins 4017623 Magnetic Switch Bracket is an integral component in various engine systems, facilitating the secure and efficient mounting of magnetic switches. This bracket is designed to work seamlessly with a range of engine accessories and electric starting systems, ensuring reliable performance and integration.

Integration with Electric Starting Systems

In electric starting systems, particularly those utilizing a Dual Delco-Remy 24V Start configuration, the Magnetic Switch Bracket plays a significant role. It provides a stable mounting solution for the magnetic switch, which is essential for the operation of the starter. The bracket ensures that the magnetic switch remains firmly in place, allowing for consistent and reliable engagement of the starter motor. This is particularly important in high-vibration environments typical of engine operation 9.

Compatibility with Electric System Kits

When incorporated into an Electric System Kit, the Magnetic Switch Bracket enhances the overall reliability of the system. It supports the magnetic switch, which controls the flow of electricity to the starter, ensuring that the starting process is smooth and efficient. The bracket’s design allows for easy installation and adjustment, making it a versatile component in various electric system configurations 10.

Instrument Panel Mounting

The Magnetic Switch Bracket is also utilized in Instrument Panel Mounting applications. It securely holds the magnetic switch in place on the instrument panel, ensuring that the switch operates correctly within the electrical system. This is vital for the accurate functioning of the instrument panel, as it relies on precise electrical signals to display essential engine information to the operator 11.

Magnetic Mounting Switch Applications

In systems where a Magnetic Mounting Switch is employed, the bracket ensures that the switch is correctly positioned and maintained. This is particularly important in environments where space is limited, and precise component placement is necessary for optimal performance. The bracket’s magnetic properties aid in securing the switch without the need for additional fasteners, simplifying the installation process 12.

Starter and Starter 12 Volt Systems

For Starter and Starter 12 Volt Systems, the Magnetic Switch Bracket is essential for the proper functioning of the starter motor. It ensures that the magnetic switch, which activates the starter, is securely mounted and can operate under the stresses of engine starting. This is particularly important in 12-volt systems, where the starter motor must engage quickly and reliably to start the engine 13.

Conclusion

The Cummins 4017623 Magnetic Switch Bracket is a versatile and essential component in various engine systems. Its role in securely mounting magnetic switches ensures the reliable operation of electric starting systems, instrument panels, and starter motors. Whether in high-vibration environments or space-constrained applications, this bracket provides the necessary stability and support for optimal system performance.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388711.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388711.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388711.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388711.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388711.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388711.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388711.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388711.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.