This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4011091 Switch Bracket is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s electrical system, contributing to the overall operation and efficiency of the truck. Understanding its purpose and significance can help in maintaining and troubleshooting the vehicle’s electrical components.

Basic Concepts of Switch Brackets

A switch bracket is a mounting component used to secure switches, relays, or other electrical components in place. It ensures that these components are held firmly and are properly aligned within the vehicle’s electrical system. The switch bracket integrates with various electrical components, providing a stable platform for their operation and contributing to the efficient functioning of the vehicle’s electrical circuits 1.

Purpose of the Cummins 4011091 Switch Bracket

The Cummins 4011091 Switch Bracket plays a role in the operation of a truck by securely mounting electrical switches and relays. This ensures that these components are correctly positioned and protected, allowing for reliable electrical connections and efficient operation of the truck’s systems. Its function within the electrical system is vital for the proper signaling and control of various truck functions 2.

Key Features

The Cummins 4011091 Switch Bracket is constructed from durable materials, ensuring longevity and resistance to wear and tear. Its design includes specific elements that allow for easy installation and secure mounting of electrical components. Unique attributes may include corrosion resistance and compatibility with a range of switch and relay types, enhancing its versatility and reliability in various operating conditions 3.

Benefits

The Cummins 4011091 Switch Bracket offers several benefits, including enhanced durability due to its material construction. It facilitates ease of installation, reducing downtime during maintenance or repair procedures. Additionally, its reliable performance in various operating conditions ensures consistent electrical system functionality, contributing to the overall efficiency and safety of the truck.

Installation Process

Installing the Cummins 4011091 Switch Bracket involves several steps to ensure proper placement and functionality. Begin by identifying the correct location for the bracket within the truck’s electrical system. Use the appropriate tools to secure the bracket in place, ensuring it is firmly attached. Connect the electrical components to the bracket, following the manufacturer’s guidelines for wiring and connections. Finally, test the installation to confirm that all components are securely mounted and functioning correctly.

Troubleshooting Common Issues

Common problems with switch brackets may include loose connections, corrosion, or damage to the bracket itself. To troubleshoot these issues, first, inspect the bracket and connections for signs of wear or corrosion. Tighten any loose connections and clean the bracket and surrounding areas to remove any corrosion. If the bracket is damaged, it may need to be replaced to ensure the electrical system’s reliability.

Maintenance Tips

Regular maintenance of the Cummins 4011091 Switch Bracket involves inspecting it for signs of wear, corrosion, or damage. Cleaning the bracket and its connections can prevent corrosion and ensure reliable electrical connections. Additionally, checking the tightness of all connections and the bracket’s securement can help maintain the electrical system’s efficiency and safety.

Compatibility and Applications

The Cummins 4011091 Switch Bracket is designed for use in specific types of trucks and engine models. Its compatibility ensures that it can be effectively integrated into the electrical systems of these vehicles, providing reliable performance and durability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the commercial truck industry, providing reliable and efficient power solutions for a wide range of applications.

Cummins Switch Bracket 4011091 Compatibility with Engine Models

The Cummins Switch Bracket part number 4011091 is designed to fit seamlessly with a range of Cummins engine models. This part is integral to the proper functioning of the engine’s electrical and control systems, ensuring reliable operation and performance.

QSV81G and QSV91G Engines

The Switch Bracket 4011091 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and efficiency, making them suitable for heavy-duty applications. The bracket’s precise fit ensures that the electrical switches are securely mounted, facilitating smooth operation and reducing the risk of electrical faults.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the Switch Bracket 4011091 is engineered to integrate perfectly with the engine’s architecture. This compatibility is crucial for maintaining the integrity of the engine’s electrical pathways, ensuring that all switches are properly aligned and secured. The bracket’s design accommodates the specific layout of these engines, providing a stable and reliable mounting solution.

QSW27 and QSW36 Engines

The Switch Bracket 4011091 also fits the QSW27 and QSW36 engines. These engines are part of Cummins’ lineup of smaller, yet powerful, engines designed for various applications. The bracket’s compatibility with these models ensures that the electrical switches are correctly positioned, enhancing the overall reliability and performance of the engines.

QSW73 Engine

Lastly, the QSW73 engine is another model that benefits from the Switch Bracket 4011091. This bracket is tailored to fit the unique specifications of the QSW73, ensuring that the electrical components are securely mounted and functioning optimally. The bracket’s design supports the engine’s operational needs, contributing to its overall efficiency and durability.

Role of Part 4011091 Switch Bracket in Engine Systems

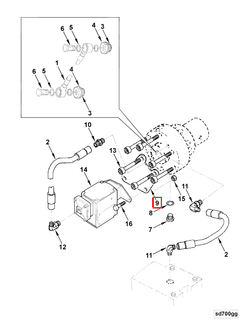

The 4011091 Switch Bracket is an integral component in the assembly and operation of various engine systems. It serves as a mounting point for switches that are essential for the monitoring and control of engine functions.

In the Engine Monitoring System, the Switch Bracket secures switches that monitor parameters such as temperature, pressure, and RPM. These switches provide real-time data to the engine control unit, allowing for precise adjustments and ensuring optimal performance.

Within the Lubricating Oil Pressure Assembly, the Switch Bracket holds switches that detect the pressure levels of the lubricating oil. This is vital for maintaining the correct viscosity and flow of oil to critical engine components, thereby preventing wear and ensuring smooth operation.

In the broader Lubricating Oil Pressure System, the Switch Bracket facilitates the integration of switches that monitor oil pressure throughout the system. This enables the detection of any anomalies or drops in pressure, which could indicate a leak or malfunction, allowing for timely intervention.

Overall, the Switch Bracket plays a significant role in ensuring that all interconnected systems within the engine operate harmoniously. By providing a stable mounting solution for essential switches, it contributes to the reliability and efficiency of the engine’s performance.

Conclusion

The Cummins 4011091 Switch Bracket is a vital component in the electrical systems of commercial trucks, ensuring the secure mounting of switches and relays. Its durable construction, ease of installation, and reliable performance contribute to the overall efficiency and safety of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.