This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

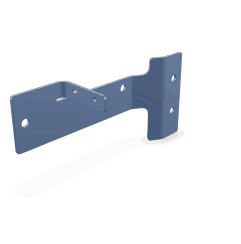

The Wiring Retainer Bracket, part number 4009598, manufactured by Cummins, is a component designed to enhance the functionality and reliability of commercial truck electrical systems. Cummins, a well-established name in the automotive and heavy-duty truck industries, produces this bracket to meet the demanding requirements of commercial operations. The significance of this part lies in its role in maintaining the integrity and efficiency of the truck’s electrical system, which is vital for safe and reliable vehicle performance 2.

Purpose and Function

This part plays a role in the electrical system of a truck by securing and organizing wiring harnesses. This function is important for preventing damage to the wires and ensuring reliable electrical connections. By keeping the wiring harnesses in place, the bracket helps to protect the wires from abrasion, vibration, and other potential sources of damage that could lead to electrical failures 2.

Key Features

The design and material characteristics of the Wiring Retainer Bracket contribute to its effectiveness and longevity. Constructed from durable materials, the bracket is resistant to corrosion, which is particularly important in the harsh environments often encountered by commercial trucks. Its design allows for compatibility with various wiring configurations, providing flexibility in installation and use across different truck models 2.

Benefits

The advantages provided by the Wiring Retainer Bracket include improved reliability of the electrical system, reduced risk of short circuits, and enhanced overall safety and performance of the truck. By securing the wiring harnesses, the bracket helps to maintain consistent electrical connections, which is important for the operation of various truck systems. This contributes to the truck’s safety and efficiency, reducing the likelihood of electrical failures that could lead to downtime or accidents 2.

Installation and Maintenance

Proper installation of the Wiring Retainer Bracket is important for ensuring its effectiveness. Recommended procedures involve securing the bracket in the designated location using the appropriate tools to avoid damage to the bracket or the wiring harnesses. Maintenance tips include regular inspection of the bracket and wiring harnesses for signs of wear or damage, and ensuring that all connections remain secure. This helps to ensure the longevity and optimal performance of the bracket 2.

Troubleshooting Common Issues

Common problems associated with Wiring Retainer Brackets may include loose connections or bracket damage. Troubleshooting steps involve inspecting the bracket and wiring harnesses for any signs of wear or damage, ensuring that all connections are secure, and replacing any damaged components as necessary. Addressing these issues promptly helps to maintain the reliability and safety of the truck’s electrical system 2.

Regulatory Compliance

The Wiring Retainer Bracket complies with industry standards and regulations governing truck electrical systems. This compliance ensures that the bracket meets the necessary safety and reliability requirements for use in commercial operations, contributing to the overall safety and performance of the truck 1.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and commercial truck industries, with a history of producing high-quality parts and engines. The company’s product offerings include a wide range of components designed to enhance the performance, reliability, and efficiency of commercial vehicles. Cummins’ reputation in the industry is built on its commitment to quality, innovation, and customer satisfaction 2.

Cummins Engine Compatibility with Wiring Retainer Bracket Part 4009598

The Wiring Retainer Bracket, part number 4009598, manufactured by Cummins, is a component in the electrical system of certain Cummins engines. This part is designed to secure and organize wiring harnesses, ensuring that electrical connections remain stable and protected from potential damage.

QSK19 CM500

The QSK19 CM500 engine is part of Cummins’ QSK series, which is known for its robust design and high performance. The Wiring Retainer Bracket part 4009598 is specifically engineered to fit seamlessly within the engine’s architecture, providing a reliable means to manage and secure the wiring. This bracket is important for maintaining the integrity of the electrical system, ensuring that all connections are properly managed and protected.

Grouping of Engines

While the QSK19 CM500 is a notable example, the Wiring Retainer Bracket part 4009598 is also compatible with other models within the Cummins QSK series. This part is designed to be versatile, fitting various engine configurations while maintaining its primary function of securing wiring harnesses. The bracket’s design allows for easy installation and adjustment, making it a valuable component for both original equipment and aftermarket applications.

The compatibility of the Wiring Retainer Bracket part 4009598 with the QSK19 CM500 and other similar engines underscores Cummins’ commitment to providing high-quality, reliable parts that enhance the performance and longevity of their engines 2.

Role of Part 4009598 Wiring Retainer Bracket in Engine Systems

The part 4009598 Wiring Retainer Bracket is a component in the organization and protection of wiring within engine systems. Its primary function is to secure and manage the wiring harnesses that connect various engine components, ensuring they remain in place and are protected from potential damage.

Integration with the Engine Control Module (ECM)

When integrating with the Engine Control Module (ECM), the Wiring Retainer Bracket plays a role in maintaining the integrity of the electrical connections. The ECM relies on a network of wires to communicate with sensors, actuators, and other control units. The bracket ensures that these wires are neatly organized and secured, reducing the risk of wire fatigue, chafing, or accidental disconnection. This organization is vital for the ECM to receive accurate data from sensors and send precise commands to actuators, thereby ensuring optimal engine performance and efficiency 2.

Interaction with the Engine

In the context of the engine itself, the Wiring Retainer Bracket helps in managing the wiring that runs through various engine compartments. This includes securing wires that connect to the fuel injectors, ignition coils, and other critical engine components. By keeping these wires organized and protected, the bracket helps prevent issues such as short circuits or damage from heat and vibration, which are common in the engine environment. This protection ensures that the engine receives consistent electrical signals, contributing to reliable operation and reduced maintenance needs 2.

Overall System Benefits

The use of the Wiring Retainer Bracket in engine systems offers several benefits. It enhances the durability of the wiring by shielding it from physical stress and environmental factors. Additionally, it simplifies the troubleshooting process by keeping wires easily accessible and organized, allowing for quicker identification and resolution of electrical issues. This component is a small yet significant part of maintaining the overall health and performance of engine systems 2.

Conclusion

The Wiring Retainer Bracket, part number 4009598, manufactured by Cummins, is a vital component in the electrical systems of commercial trucks and Cummins engines. Its role in securing and organizing wiring harnesses ensures the reliability and safety of the electrical system, contributing to the overall performance and efficiency of the vehicle. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part, ensuring the longevity and optimal operation of the truck’s electrical system 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.