This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

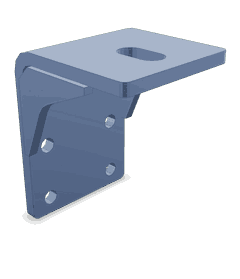

The Marine Gear Bracket 4003452, manufactured by Cummins, is a component designed for use in commercial trucks. It plays a role in the functionality of truck transmissions by providing structural support and facilitating the integration of various transmission components. Understanding the role of marine gear brackets is important for maintaining and optimizing the performance of heavy-duty truck transmissions.

Basic Concepts of Marine Gear Brackets

A marine gear bracket is a structural component that supports and aligns the gears within a transmission system. Its primary functions include securing gears in place, ensuring proper alignment, and distributing mechanical loads. The bracket integrates with the transmission system by connecting to both the transmission housing and the gears, allowing for smooth operation and efficient power transfer. The mechanical principles behind its operation involve the precise alignment of gears to minimize friction and wear, and the distribution of forces to prevent component failure 1.

Purpose of the 4003452 Marine Gear Bracket

The 4003452 Marine Gear Bracket supports the transmission system by providing a stable mounting point for gears and other components. It contributes to the truck’s performance and durability by ensuring that the gears remain properly aligned and securely in place, which is important for efficient power transmission and reduced wear on transmission components.

Key Features

The 4003452 Marine Gear Bracket features a durable material composition, typically consisting of high-strength steel or cast iron, which provides resistance to wear and corrosion. Its design includes precise mounting points and alignment features to ensure accurate gear placement. Additionally, the bracket may incorporate unique attributes such as vibration dampening elements or enhanced surface coatings to further improve its functionality and reliability.

Benefits

Using the 4003452 Marine Gear Bracket in truck transmissions offers several advantages. These include improved durability due to its robust material and design, enhanced performance through precise gear alignment, and potential cost savings over time as a result of reduced maintenance and repair needs. The bracket’s reliable operation contributes to the overall efficiency and longevity of the transmission system.

Installation Process

Installing the 4003452 Marine Gear Bracket involves several steps to ensure proper integration with the truck’s transmission system. Begin by preparing the transmission housing and ensuring it is clean and free of debris. Align the bracket with the mounting points and secure it in place using the appropriate fasteners. Verify that the bracket is properly aligned with the gears and other components, making any necessary adjustments. Finally, conduct a thorough inspection to confirm that all connections are secure and that the bracket is functioning as intended.

Troubleshooting and Maintenance

Common issues associated with marine gear brackets include misalignment, wear, and corrosion. To troubleshoot these problems, inspect the bracket for signs of damage or wear, check the alignment of the gears, and ensure that all fasteners are secure. Regular maintenance tips to prolong the life of the 4003452 Marine Gear Bracket include cleaning the bracket and surrounding components, applying protective coatings as needed, and performing routine inspections to identify and address any issues early.

Cummins: Manufacturer Overview

Cummins is a well-established manufacturer with a strong reputation in the heavy-duty truck industry. Founded in 1919, Cummins has a history of innovation and quality in engine and component manufacturing. Their range of products for heavy-duty trucks includes engines, transmissions, and various components designed to enhance performance and reliability. Cummins is trusted by professionals in the industry for their commitment to quality and durability, making them a preferred choice for truck components 2.

Cummins Marine Gear Bracket 4003452 Compatibility

The Cummins Marine Gear Bracket part number 4003452 is designed to fit seamlessly with a range of Cummins marine engines, ensuring robust and reliable performance in marine applications. This bracket is integral to the proper functioning of the engine’s gear system, providing a secure mounting point that helps maintain alignment and stability.

Engine Compatibility

-

6C8.3 Series: The 4003452 bracket is specifically engineered to fit the 6C8.3 series engines. This series is known for its durability and efficiency, making it a popular choice for marine environments. The bracket’s design ensures that it can withstand the rigors of marine use, providing a stable connection between the engine and the gear system.

-

Other Cummins Marine Engines: While the primary focus is on the 6C8.3 series, the 4003452 bracket is also compatible with other Cummins marine engines. This compatibility extends to various engine models within the Cummins marine engine lineup, ensuring that users can find a suitable fit for their specific engine type.

Installation and Usage

Proper installation of the Cummins Marine Gear Bracket 4003452 is crucial for maintaining the integrity of the engine’s gear system. The bracket should be installed according to the manufacturer’s guidelines, ensuring that all bolts and fasteners are tightened to the specified torque settings. This will help prevent any loosening or misalignment over time, which could lead to performance issues or damage to the engine.

Maintenance

Regular maintenance of the 4003452 bracket is essential to ensure its longevity and effectiveness. Periodic inspections should be conducted to check for any signs of wear, corrosion, or damage. If any issues are detected, the bracket should be repaired or replaced as necessary to maintain the engine’s performance and reliability.

By ensuring that the Cummins Marine Gear Bracket 4003452 is properly installed and maintained, marine engine operators can enjoy the benefits of a secure and stable gear system, contributing to the overall efficiency and durability of their engines.

Role of Part 4003452 Marine Gear Bracket in Engine Systems

The 4003452 Marine Gear Bracket is an essential component that interfaces with various elements of the engine system, ensuring efficient and reliable operation.

Integration with the Support System

The Marine Gear Bracket is designed to provide a stable mounting point for the marine gear within the engine assembly. It securely attaches to the support structure, which typically includes the engine bed or frame. This bracket ensures that the marine gear remains firmly in place, minimizing vibrations and potential misalignments that could lead to operational inefficiencies or damage. The support system, in turn, relies on the bracket to distribute the load evenly, enhancing the overall stability of the engine setup.

Interaction with the Power Train

In the context of the power train, the 4003452 Marine Gear Bracket plays a significant role in transmitting power from the engine to the propulsion system. It connects the marine gear to the power train components, such as the transmission and driveshaft. This connection is vital for the smooth transfer of rotational force, ensuring that the engine’s power is effectively translated into forward motion. The bracket’s precise alignment and secure fit are essential for maintaining the integrity of the power train, reducing wear and tear on connected components, and enhancing the engine’s performance and durability 3.

Conclusion

The 4003452 Marine Gear Bracket is a critical component in the functionality of heavy-duty truck transmissions. Its role in providing structural support, ensuring proper gear alignment, and facilitating efficient power transfer is essential for the performance and durability of the transmission system. Proper installation, regular maintenance, and understanding its integration within the engine system are key to maximizing the benefits of this Cummins part.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.