This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

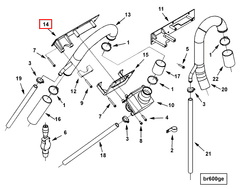

The Cummins 4000948 Breather Bracket is a component designed to facilitate ventilation and pressure regulation within the engine system of heavy-duty trucks. Its purpose is to ensure that the engine operates efficiently by managing the airflow and pressure within the crankcase. This component is integral to maintaining the overall health and performance of the engine 1.

Function and Operation

The Breather Bracket operates by allowing air to enter and exit the engine’s crankcase, which helps in maintaining optimal pressure levels. This process is vital for the proper lubrication of engine components and the removal of contaminants that may accumulate during operation. By regulating the airflow, the breather bracket contributes to the engine’s ventilation system, which is crucial for dissipating heat and preventing the buildup of harmful gases 2.

Key Features

This Cummins part is constructed from durable materials that are resistant to corrosion and wear, ensuring longevity and reliable performance. Its design includes precise engineering to fit securely within the engine system, providing a stable platform for the breather elements. Additionally, the bracket may feature unique attributes such as integrated mounting points or seals that enhance its functionality and ease of installation 3.

Benefits of Using the Cummins 4000948 Breather Bracket

Utilizing this part can lead to improved engine performance due to its role in maintaining proper ventilation and pressure within the crankcase. This can result in enhanced engine longevity as it helps to prevent the accumulation of sludge and other contaminants. Furthermore, the design of the bracket may contribute to easier maintenance, allowing for straightforward access to the breather system components 4.

Installation Process

To install the Breather Bracket, begin by ensuring the engine is cool and the vehicle is parked on a level surface. Gather the necessary tools, which may include wrenches and screwdrivers. Follow the manufacturer’s instructions for removing the old bracket, if applicable, and then position the new bracket in place. Secure it using the provided fasteners, ensuring a snug fit without over-tightening. Finally, verify that all connections are secure and that the breather system is functioning correctly 5.

Maintenance and Troubleshooting

Regular maintenance of the Breather Bracket involves inspecting it for signs of wear or damage, such as cracks or loose fasteners. It is also important to check the breather elements for clogging or contamination, which can impede airflow. If issues are detected, such as unusual noises or a decrease in engine performance, it may be necessary to clean or replace the breather elements. Always refer to the manufacturer’s guidelines for specific maintenance procedures 6.

Safety Considerations

When installing or maintaining the Breather Bracket, it is important to follow safety guidelines to protect both personnel and equipment. Ensure that the engine is off and has cooled down before beginning any work. Use the appropriate personal protective equipment, such as gloves and safety glasses, to prevent injury. Additionally, be mindful of the tools and components being used to avoid accidents or damage to the engine system 7.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range serves various applications, from on-highway to off-highway and industrial uses, demonstrating its versatility and expertise in the field 8.

Conclusion

The 4000948 Breather Bracket is a fundamental component in the efficient operation of engine systems, particularly in its interaction with the breather, crankcase, and as part of a breather kit. Its proper installation and function are key to maintaining the health and performance of the engine.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Cummins Inc. (n.d.). ISB/ISD6.7 CM2150 B120 Service Manual (4358470).

↩ -

Cummins Inc. (n.d.). ISB/ISD6.7 CM2150 B120 Service Manual (4358470).

↩ -

Cummins Inc. (n.d.). ISB/ISD6.7 CM2150 B120 Service Manual (4358470).

↩ -

Cummins Inc. (n.d.). ISB/ISD6.7 CM2150 B120 Service Manual (4358470).

↩ -

Cummins Inc. (n.d.). ISB/ISD6.7 CM2150 B120 Service Manual (4358470).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.